Blanching involves briefly boiling vegetables to deactivate enzymes and preserve color, flavor, and texture, while shock-chilling rapidly cools them in ice water to stop the cooking process immediately. This combination helps maintain optimal freshness and nutrient retention during vegetable preparation. Compared to shock-chilling alone, blanching is essential for improving shelf life and preventing spoilage in frozen or refrigerated vegetables.

Table of Comparison

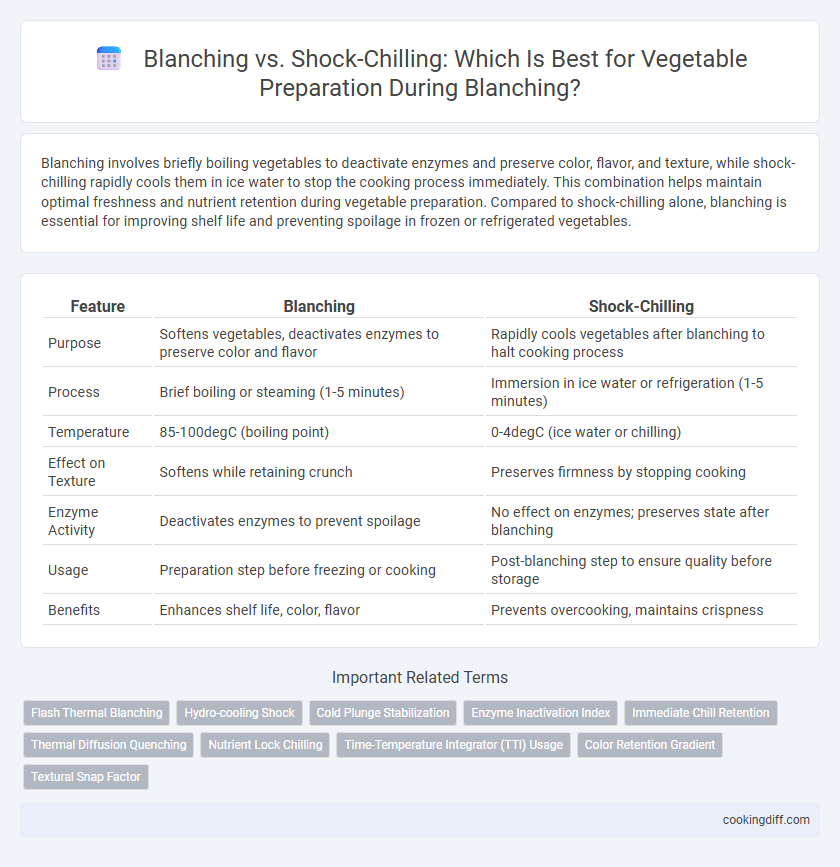

| Feature | Blanching | Shock-Chilling |

|---|---|---|

| Purpose | Softens vegetables, deactivates enzymes to preserve color and flavor | Rapidly cools vegetables after blanching to halt cooking process |

| Process | Brief boiling or steaming (1-5 minutes) | Immersion in ice water or refrigeration (1-5 minutes) |

| Temperature | 85-100degC (boiling point) | 0-4degC (ice water or chilling) |

| Effect on Texture | Softens while retaining crunch | Preserves firmness by stopping cooking |

| Enzyme Activity | Deactivates enzymes to prevent spoilage | No effect on enzymes; preserves state after blanching |

| Usage | Preparation step before freezing or cooking | Post-blanching step to ensure quality before storage |

| Benefits | Enhances shelf life, color, flavor | Prevents overcooking, maintains crispness |

Understanding Blanching: A Quick Overview

Blanching involves briefly boiling vegetables to inactivate enzymes and preserve color, texture, and nutritional value. Shock-chilling rapidly cools blanched vegetables using ice water to halt the cooking process and maintain freshness.

- Enzyme Inactivation - Blanching stops enzymatic activity that causes spoilage and degradation in vegetables.

- Texture Preservation - Quick cooking during blanching helps maintain the desired firmness and crispness.

- Rapid Cooling - Shock-chilling prevents overcooking and microbial growth by quickly lowering temperature.

Blanching combined with shock-chilling optimizes vegetable quality for storage and further processing.

What Is Shock-Chilling in Vegetable Preparation?

Shock-chilling in vegetable preparation rapidly cools blanched vegetables by immersing them in ice water or using chilled air, halting the cooking process quickly. This technique preserves color, texture, and nutritional value, enhancing the overall quality of vegetables.

Unlike blanching, which uses hot water or steam to inactivate enzymes, shock-chilling immediately reduces temperature to prevent overcooking. The combination of blanching followed by shock-chilling is essential for maintaining freshness and extending shelf life in commercial vegetable processing.

Key Differences Between Blanching and Shock-Chilling

Blanching involves briefly boiling vegetables to inactivate enzymes and preserve color, texture, and nutritional value, while shock-chilling rapidly cools them in ice water to halt the cooking process. Blanching primarily prepares vegetables for freezing or further cooking, whereas shock-chilling is used immediately after blanching to prevent overcooking and maintain freshness. The key difference lies in their temperature and purpose: blanching applies heat to damage enzymes, and shock-chilling applies cold to quickly stop the heat's effect.

Benefits of Blanching Vegetables

Blanching vegetables involves briefly boiling them to inactivate enzymes, preserving color, flavor, and nutritional value more effectively than shock-chilling. This process reduces microbial load and softens vegetables, enhancing texture and shelf-life during storage and further processing.

Blanching helps maintain vitamin content and improve food safety by destroying harmful pathogens. Unlike shock-chilling, blanching prepares vegetables for freezing by preventing enzymatic browning and nutrient degradation, ensuring higher quality in frozen produce.

Advantages of Shock-Chilling for Freshness

Shock-chilling rapidly reduces the temperature of blanched vegetables, preserving vibrant color, texture, and nutritional value better than traditional blanching alone. This process minimizes enzymatic activity and microbial growth, extending shelf life and maintaining freshness during storage. The quick temperature drop also limits moisture loss, ensuring vegetables retain their natural crispness and flavor.

Effects on Nutrient Retention: Blanching vs Shock-Chilling

Blanching temporarily heats vegetables to inactivate enzymes, preserving color and texture while causing minimal nutrient loss, especially of vitamin C and B vitamins. Shock-chilling immediately cools blanched vegetables to halt cooking, effectively retaining water-soluble vitamins and preventing overcooking.

Blanching can cause slight degradation of heat-sensitive nutrients but improves overall nutrient stability by slowing enzymatic activity. Shock-chilling locks in nutrients by rapidly lowering the temperature, reducing oxidative damage and preserving antioxidant compounds. Combining blanching with shock-chilling optimizes nutrient retention and extends shelf life, making it a preferred method in vegetable preparation.

Best Vegetables for Blanching and Shock-Chilling

Blanching is ideal for dense, fibrous vegetables like green beans, broccoli, and carrots to preserve texture and color. Shock-chilling best suits delicate vegetables such as asparagus, peas, and spinach to halt cooking quickly and maintain crispness.

- Green Beans and Broccoli for Blanching - These vegetables withstand high-temperature blanching, which preserves nutrients and enhances color retention.

- Carrots for Blanching - Blanching softens carrots while maintaining firmness, making them ideal for freezing and extended storage.

- Asparagus and Peas for Shock-Chilling - Rapid cooling after blanching retains their vibrant green color and prevents overcooking, ensuring a crisp texture.

Step-by-Step Guide: Blanching vs Shock-Chilling Methods

Blanching involves briefly boiling vegetables to deactivate enzymes, preserving texture and color, while shock-chilling rapidly cools them to halt cooking and maintain freshness. These complementary techniques optimize vegetable preparation by balancing heat treatment and immediate cooling.

- Blanching - Submerge vegetables in boiling water for 1-5 minutes, depending on type and size, to inactivate enzymes and soften fibers.

- Shock-chilling - Immediately transfer blanched vegetables into ice-cold water or an ice bath to rapidly reduce temperature and stop the cooking process.

- Drying and Storage - Drain and dry vegetables thoroughly after shock-chilling to prevent ice crystals and preserve texture before packaging or freezing.

Common Mistakes to Avoid in Both Techniques

| Common mistakes in blanching include undercooking vegetables, which leads to poor enzyme inactivation, and overheating, causing nutrient loss and texture degradation. Shock-chilling errors often involve inadequate ice bath timing, resulting in incomplete cooling and potential microbial growth. Both techniques require precise timing and temperature control to maintain vegetable quality and safety. |

Related Important Terms

Flash Thermal Blanching

Flash Thermal Blanching offers rapid heat treatment that preserves nutrient content and texture better than traditional blanching, while shock-chilling rapidly cools vegetables to halt cooking and microbial growth, optimizing freshness and shelf life. Combining Flash Thermal Blanching with shock-chilling maximizes enzyme inactivation and maintains sensory quality, making it ideal for high-quality vegetable preparation.

Hydro-cooling Shock

Blanching effectively inactivates enzymes and preserves vegetable color and texture, but Hydro-cooling Shock, a rapid cooling method using chilled water, minimizes nutrient loss and prevents microbial growth more efficiently by quickly reducing produce temperature. Hydro-cooling Shock enhances shelf life and maintains sensory quality better than traditional blanching followed by air cooling.

Cold Plunge Stabilization

Blanching involves briefly heating vegetables to inactivate enzymes before cold plunge stabilization rapidly cools them in ice water to halt cooking and preserve texture. Cold plunge stabilization after blanching improves product quality by maintaining firmness, color, and nutritional content while preventing microbial growth.

Enzyme Inactivation Index

Blanching significantly reduces the Enzyme Inactivation Index by denaturing enzymes such as polyphenol oxidase and peroxidase, thereby preserving vegetable texture and color. In contrast, shock-chilling primarily lowers the temperature rapidly without effectively inactivating enzymes, resulting in a higher residual Enzyme Inactivation Index and potential quality degradation during storage.

Immediate Chill Retention

Blanching deactivates enzymes in vegetables to preserve color, texture, and nutrients, but immediate chill retention is crucial to halt cooking and prevent microbial growth. Shock-chilling rapidly reduces the temperature of blanched vegetables, enhancing quality retention by minimizing thermal degradation and extending shelf life.

Thermal Diffusion Quenching

Blanching uses hot water or steam to rapidly heat vegetables, inactivating enzymes and initiating thermal diffusion, whereas shock-chilling rapidly cools blanched vegetables to halt thermal diffusion and prevent overcooking. Thermal diffusion quenching is critical in shock-chilling as it rapidly lowers the internal temperature, preserving texture and nutrient retention in vegetable preparation.

Nutrient Lock Chilling

Blanching involves briefly boiling vegetables to inactivate enzymes, preserving color and texture while reducing nutrient loss, whereas shock-chilling rapidly cools blanched vegetables to halt cooking and lock in nutrients effectively. Nutrient lock chilling minimizes vitamin degradation and maintains antioxidant levels, ensuring optimal retention of essential nutrients in prepared vegetables.

Time-Temperature Integrator (TTI) Usage

Blanching involves briefly exposing vegetables to boiling water or steam to inactivate enzymes, while shock-chilling rapidly cools the produce to halt cooking and preserve texture. Time-Temperature Integrators (TTIs) optimize quality control by monitoring cumulative heat exposure during blanching and cooling phases, ensuring precise adherence to processing parameters for optimal vegetable preservation.

Color Retention Gradient

Blanching improves color retention in vegetables by inactivating enzymes that cause discoloration, resulting in a vivid and stable color gradient during cooking and storage. Shock-chilling rapidly cools blanched vegetables, preserving the enhanced color gradient by halting residual enzymatic activity and preventing pigment degradation.

Blanching vs Shock-chilling for vegetable prep. Infographic

cookingdiff.com

cookingdiff.com