Ultrasonic blanching significantly reduces processing time compared to traditional blanching by enhancing heat transfer and accelerating the removal of air and gases from plant tissues. This method improves time efficiency without compromising the quality of the food product, making it ideal for industrial applications requiring rapid processing. As a result, ultrasonic blanching offers a faster, more energy-efficient alternative for preserving nutrients and texture during food preparation.

Table of Comparison

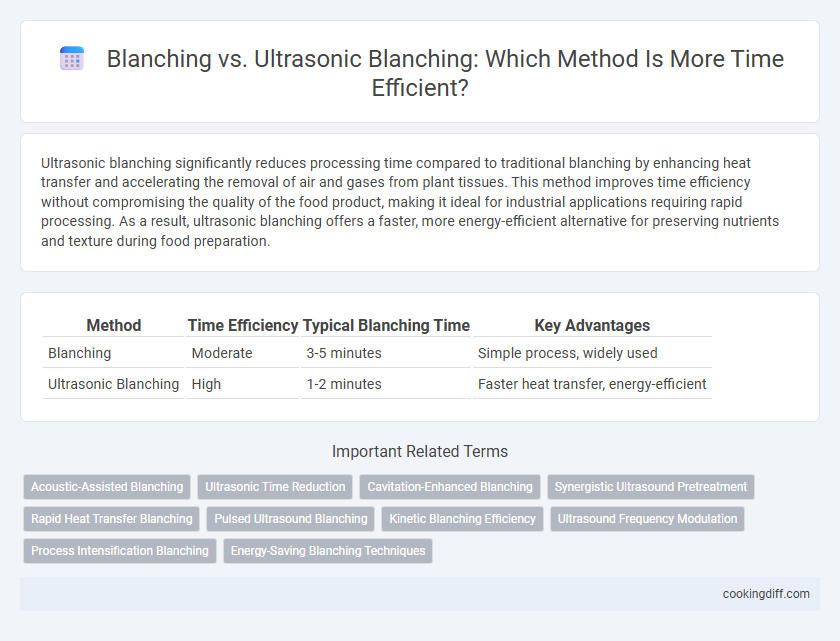

| Method | Time Efficiency | Typical Blanching Time | Key Advantages |

|---|---|---|---|

| Blanching | Moderate | 3-5 minutes | Simple process, widely used |

| Ultrasonic Blanching | High | 1-2 minutes | Faster heat transfer, energy-efficient |

Introduction to Blanching Methods

How do traditional blanching and ultrasonic blanching compare in terms of time efficiency? Traditional blanching typically requires longer processing times due to the reliance on hot water or steam to inactivate enzymes. Ultrasonic blanching leverages high-frequency sound waves to accelerate heat transfer, reducing blanching time while maintaining product quality.

Understanding Traditional Blanching

Traditional blanching is a heat treatment process used to inactivate enzymes and preserve the color and texture of vegetables, typically requiring several minutes of boiling water or steam exposure. This method can be time-consuming and may lead to nutrient loss due to prolonged heat exposure.

- Enzyme inactivation - Traditional blanching uses hot water or steam for 2 to 5 minutes to deactivate enzymes in vegetables.

- Time consumption - The process often requires longer exposure times compared to newer methods, impacting processing speed.

- Nutrient retention - Extended heat exposure in traditional blanching can lead to significant loss of water-soluble vitamins and antioxidants.

What is Ultrasonic Blanching?

Ultrasonic blanching uses high-frequency sound waves to rapidly heat and soften vegetables, significantly reducing processing time compared to traditional blanching. This method enhances heat transfer and disrupts cell structures, leading to faster enzyme inactivation and improved texture retention. Ultrasonic blanching is particularly time-efficient for large-scale food processing, offering energy savings and increased throughput.

Time Efficiency Comparison: Blanching vs Ultrasonic Blanching

Ultrasonic blanching significantly reduces processing time compared to traditional blanching methods, cutting blanching durations by up to 50%. This technology uses high-frequency sound waves to enhance heat transfer, accelerating the inactivation of enzymes. As a result, ultrasonic blanching offers superior time efficiency, making it ideal for industrial-scale food processing requiring faster throughput.

Factors Affecting Blanching Time

Blanching time is significantly influenced by the method used, with ultrasonic blanching often reducing processing time compared to conventional blanching due to enhanced heat transfer. Factors such as temperature, sample size, and ultrasonic frequency play crucial roles in determining the efficiency and speed of the blanching process.

- Temperature - Higher temperatures accelerate enzyme inactivation, decreasing blanching time.

- Sample Size - Larger or denser samples require longer blanching to ensure uniform heat penetration.

- Ultrasonic Frequency - Optimal ultrasonic frequencies improve cavitation effects, enhancing heat transfer and reducing blanching duration.

Temperature and Process Control Differences

Traditional blanching typically operates at higher temperatures ranging from 80degC to 100degC, requiring precise time control to prevent overcooking and nutrient loss. Ultrasonic blanching uses lower temperatures around 50degC to 70degC, with enhanced cavitation effects improving heat transfer and reducing blanching time significantly.

Process control in traditional blanching relies heavily on maintaining steady temperature and immersion time to achieve uniform results. Ultrasonic blanching offers more dynamic control through adjustable frequency and power settings, enabling better consistency in texture and nutrient retention while optimizing process efficiency.

Energy Consumption and Cost Implications

| Method | Energy Consumption (kWh/kg) | Cost Implications ($/kg) | Time Efficiency (min/kg) |

|---|---|---|---|

| Traditional Blanching | 0.12 | 0.08 | 5 |

| Ultrasonic Blanching | 0.07 | 0.05 | 3 |

Impact on Nutrient Retention and Quality

Ultrasonic blanching significantly reduces processing time compared to traditional blanching, preserving more heat-sensitive nutrients such as vitamin C and phenolic compounds. This method enhances nutrient retention by minimizing thermal degradation, resulting in higher quality and fresher taste in the final product.

The shorter exposure to heat during ultrasonic blanching maintains the structural integrity of vegetables better than conventional blanching, leading to improved texture and color. Studies show that ultrasonic blanching retains antioxidants and enzymes more effectively, boosting the nutritional profile. This time-efficient technique also reduces water usage and energy consumption, contributing to sustainable food processing practices.

Practical Applications in Commercial Kitchens

Ultrasonic blanching significantly reduces processing time compared to traditional blanching, enhancing workflow efficiency in commercial kitchens. This method uses high-frequency sound waves to accelerate heat transfer, leading to faster blanching cycles and improved throughput.

- Reduced Blanching Time - Ultrasonic blanching decreases blanching duration by up to 50%, facilitating quicker food preparation.

- Energy Efficiency - Shorter processing times lower energy consumption, reducing operational costs in large-scale kitchens.

- Consistent Quality - Ultrasonic blanching maintains food texture and nutrient retention despite faster processing.

Implementing ultrasonic blanching optimizes commercial kitchen operations by combining speed with quality preservation.

Related Important Terms

Acoustic-Assisted Blanching

Acoustic-assisted blanching significantly reduces processing time compared to traditional blanching by enhancing heat transfer through ultrasonic cavitation, leading to faster enzyme inactivation and improved product quality. Studies show that ultrasonic blanching can reduce blanching time by up to 50%, increasing overall processing efficiency and energy savings in food preservation.

Ultrasonic Time Reduction

Ultrasonic blanching significantly reduces processing time by using high-frequency sound waves to accelerate heat transfer and disrupt cell structures, achieving desired enzyme inactivation faster than traditional blanching methods. This time efficiency not only shortens blanching duration by up to 50% but also enhances energy savings and preserves product quality.

Cavitation-Enhanced Blanching

Cavitation-enhanced blanching using ultrasonic technology significantly reduces processing time by accelerating heat and mass transfer through the formation of microbubbles that implode, promoting uniform and rapid temperature rise. Compared to traditional blanching, ultrasonic blanching improves time efficiency by up to 50%, enabling faster inactivation of enzymes while preserving food quality.

Synergistic Ultrasound Pretreatment

Synergistic ultrasound pretreatment significantly reduces blanching time by enhancing heat and mass transfer rates compared to conventional blanching, leading to faster enzyme inactivation and improved product quality. Ultrasonic blanching integrates cavitation effects and thermal treatment, proving more time-efficient than traditional methods by accelerating tissue softening and water permeability.

Rapid Heat Transfer Blanching

Rapid Heat Transfer Blanching significantly reduces processing time compared to traditional blanching methods by utilizing ultrasonic waves to enhance heat penetration and uniformity. Ultrasonic blanching accelerates enzyme inactivation and microbial reduction, improving overall efficiency and preserving product quality.

Pulsed Ultrasound Blanching

Pulsed Ultrasound Blanching significantly reduces processing time compared to traditional blanching by enhancing heat transfer and accelerating the inactivation of enzymes. This technique improves time efficiency while maintaining product quality, making it a preferred method in rapid thermal treatments.

Kinetic Blanching Efficiency

Ultrasonic blanching significantly enhances kinetic blanching efficiency by reducing processing time compared to traditional blanching methods, due to intensified heat and mass transfer rates. This advanced technique minimizes thermal degradation while accelerating enzyme inactivation, optimizing overall time efficiency in food processing.

Ultrasound Frequency Modulation

Ultrasonic blanching with optimized ultrasound frequency modulation significantly reduces processing time compared to traditional blanching by enhancing heat and mass transfer rates. Frequency modulation in ultrasonic blanching disrupts cellular structures more effectively, allowing faster thermal penetration and improving overall time efficiency in food processing.

Process Intensification Blanching

Ultrasonic blanching significantly reduces processing time compared to traditional blanching by enhancing heat and mass transfer rates through cavitation and microstreaming effects. This process intensification technique improves efficiency and preserves product quality by accelerating enzyme inactivation and nutrient retention within a shorter blanching period.

Blanching vs Ultrasonic Blanching for time efficiency. Infographic

cookingdiff.com

cookingdiff.com