Blanching involves briefly heating food to inactivate enzymes, which can soften texture and cause slight nutrient loss, whereas cryogenic chilling rapidly freezes products using liquid nitrogen or carbon dioxide, preserving the original texture more effectively by preventing ice crystal formation. Cryogenic chilling is ideal for maintaining the structural integrity and crispness of delicate fruits and vegetables, ensuring superior texture retention compared to traditional blanching methods. This rapid cooling method minimizes cellular damage, resulting in a fresher mouthfeel and extended shelf life.

Table of Comparison

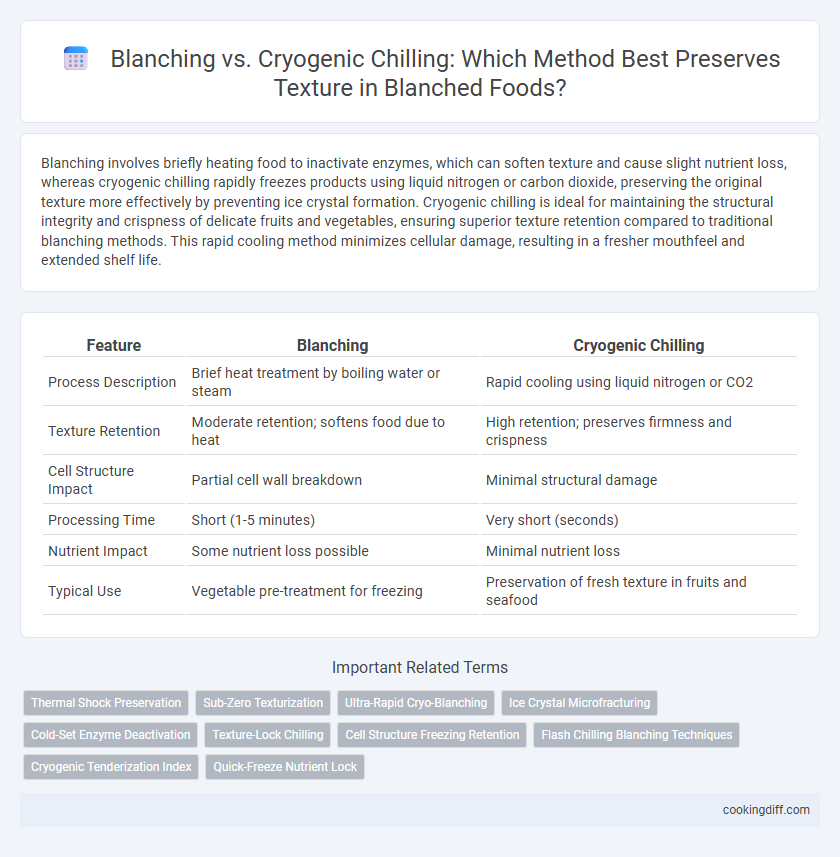

| Feature | Blanching | Cryogenic Chilling |

|---|---|---|

| Process Description | Brief heat treatment by boiling water or steam | Rapid cooling using liquid nitrogen or CO2 |

| Texture Retention | Moderate retention; softens food due to heat | High retention; preserves firmness and crispness |

| Cell Structure Impact | Partial cell wall breakdown | Minimal structural damage |

| Processing Time | Short (1-5 minutes) | Very short (seconds) |

| Nutrient Impact | Some nutrient loss possible | Minimal nutrient loss |

| Typical Use | Vegetable pre-treatment for freezing | Preservation of fresh texture in fruits and seafood |

Introduction to Texture Retention in Food Processing

Texture retention is a critical factor in food processing that affects consumer acceptance and product quality. Methods like blanching and cryogenic chilling play significant roles in preserving the structural integrity of food products.

- Blanching - Brief heat treatment that inactivates enzymes to prevent texture degradation.

- Cryogenic chilling - Rapid freezing using liquid nitrogen to preserve cellular structure and firmness.

- Texture retention impact - Cryogenic chilling generally offers superior texture preservation compared to blanching by minimizing moisture loss and cell damage.

Choosing the appropriate method depends on the desired texture and product type in food processing.

What is Blanching? Process and Purpose

What is blanching and how does it affect food texture? Blanching is a food processing method involving brief immersion of vegetables or fruits in boiling water or steam followed by rapid cooling. This process inactivates enzymes that cause spoilage and helps retain texture, color, and nutritional quality.

Understanding Cryogenic Chilling Technology

Cryogenic chilling technology utilizes ultra-low temperature gases, primarily liquid nitrogen or carbon dioxide, to rapidly reduce food temperature, preserving texture more effectively than traditional blanching. This rapid freezing process minimizes ice crystal formation, maintaining cell integrity and preventing the mushy texture often caused by blanching.

Understanding cryogenic chilling involves recognizing its ability to lock in freshness and nutritional quality by quickly arresting enzymatic activity without heat exposure. Unlike blanching, which uses hot water or steam and can lead to texture degradation, cryogenic chilling instantaneously cools product surfaces, significantly reducing moisture loss. This technology is especially beneficial in preserving the crispness and natural texture of fruits and vegetables during freezing and storage.

Comparative Impact on Food Structure

Blanching causes partial gelatinization of starch and softening of cell walls, which can lead to a loss of firmness and altered texture in vegetables. Cryogenic chilling rapidly lowers food temperature using liquid nitrogen or carbon dioxide, preserving the cellular structure and maintaining a crisp texture. Comparative studies highlight cryogenic chilling as superior for texture retention by minimizing enzymatic activity and moisture loss, unlike blanching which may compromise structural integrity.

Blanching: Effects on Texture and Nutrients

Blanching involves briefly exposing vegetables to boiling water or steam, which helps inactivate enzymes that cause texture degradation while retaining firmness. This process can cause some nutrient loss, particularly water-soluble vitamins like vitamin C and B-complex, due to heat exposure and leaching. Despite nutrient reduction, blanching effectively preserves the crisp texture desirable in frozen and canned foods, making it a preferred method for maintaining quality during storage.

Cryogenic Chilling: Preserving Freshness and Texture

Cryogenic chilling rapidly freezes produce using liquid nitrogen or carbon dioxide, preserving cellular structure and texture more effectively than blanching. This method minimizes moisture loss and maintains the freshness and crispness of fruits and vegetables.

- Rapid Freezing - Cryogenic chilling quickly lowers temperature, preventing cell damage and texture degradation.

- Moisture Retention - Unlike blanching, cryogenic chilling reduces water loss, preserving juiciness and firmness.

- Nutrient Preservation - The method locks in nutrients and freshness by avoiding heat exposure typical of blanching.

Key Advantages of Blanching vs Cryogenic Chilling

Blanching effectively inactivates enzymes that cause texture degradation, preserving the firmness of vegetables during storage and cooking. Its controlled heat treatment enhances cellular structure stability, resulting in improved texture retention compared to cryogenic chilling.

Cryogenic chilling rapidly freezes products using liquid nitrogen or carbon dioxide but may cause ice crystal formation that damages cell walls, leading to textural softening. Blanching's enzyme deactivation mechanism offers superior texture consistency, making it ideal for maintaining product quality in frozen and fresh applications.

Limitations and Challenges in Each Method

| Blanching Limitations | Blanching often causes nutrient loss, textural degradation, and color changes due to high-temperature exposure, limiting its effectiveness in preserving fresh-like texture in vegetables. |

| Cryogenic Chilling Limitations | Cryogenic chilling involves high operational costs and risk of surface frost formation, which can negatively impact product appearance and texture uniformity during rapid freezing processes. |

| Challenges Comparison | Blanching requires precise timing to avoid overcooking, while cryogenic chilling demands strict temperature control and specialized equipment; both methods pose challenges in balancing texture retention with process efficiency. |

Applications: Best Uses for Blanching and Cryogenic Chilling

Blanching is widely used in vegetable processing to inactivate enzymes and enhance color retention, making it ideal for products destined for freezing or canning. It is especially effective for leafy greens, beans, and peas where texture preservation alongside microbial control is critical.

Cryogenic chilling employs ultra-low temperatures using liquid nitrogen or carbon dioxide to rapidly cool or freeze food products, maintaining cellular integrity and minimizing moisture loss. This method is best suited for delicate fruits, seafood, and premium meat cuts requiring exceptional texture retention and quality during storage.

Related Important Terms

Thermal Shock Preservation

Blanching utilizes brief exposure to hot water or steam, causing a rapid thermal shock that denatures enzymes and partially cooks the tissue, improving texture retention by halting enzymatic degradation. Cryogenic chilling employs ultra-low temperatures to induce thermal shock through rapid freezing, preserving cellular structure and firmness by minimizing ice crystal formation and enzymatic activity.

Sub-Zero Texturization

Sub-zero texturization through cryogenic chilling preserves cellular integrity and reduces enzymatic activity, resulting in superior texture retention compared to blanching, which often causes cell wall degradation and softening. Cryogenic chilling's rapid and uniform freezing minimizes ice crystal formation, maintaining the firmness and crispness of produce better than the heat exposure involved in blanching.

Ultra-Rapid Cryo-Blanching

Ultra-Rapid Cryo-Blanching combines the enzymatic inactivation effect of blanching with the superior texture retention benefits of cryogenic chilling, minimizing cellular damage and preserving crispness in vegetables. This technique rapidly lowers the product temperature using liquid nitrogen or carbon dioxide, preventing moisture loss and maintaining structural integrity better than conventional blanching methods.

Ice Crystal Microfracturing

Blanching exposes vegetables to hot water or steam, causing partial cell wall breakdown that reduces the size and severity of ice crystal microfracturing during subsequent freezing, thereby better preserving texture. Cryogenic chilling freezes produce rapidly with liquid nitrogen, creating smaller ice crystals but can still cause microfractures that may compromise the structural integrity and texture of sensitive foods.

Cold-Set Enzyme Deactivation

Blanching effectively deactivates cold-set enzymes responsible for texture degradation by applying controlled heat, thereby preserving the firmness and crispness of vegetables. Cryogenic chilling, while preserving temperature-sensitive nutrients, is less efficient in enzyme deactivation, often resulting in compromised texture retention post-processing.

Texture-Lock Chilling

Texture-Lock chilling outperforms blanching and cryogenic chilling by preserving cell integrity and minimizing moisture loss, which enhances the firmness and crunchiness of fresh produce. This advanced chilling technique uses precise temperature control to lock in texture without the nutrient degradation typically caused by high-heat or rapid freezing methods.

Cell Structure Freezing Retention

Blanching partially denatures enzymes and softens cell walls, which can lead to some loss of cellular integrity and texture in frozen products, while cryogenic chilling rapidly freezes the product, preserving cell structure by minimizing ice crystal formation and preventing cellular rupture. This precise freezing retention in cryogenic chilling results in superior texture maintenance compared to the enzymatic and structural compromises arising from blanching.

Flash Chilling Blanching Techniques

Flash chilling blanching techniques rapidly cool blanched produce using cryogenic gases or liquid nitrogen, preserving cellular structure and minimizing texture degradation compared to traditional blanching methods. This rapid temperature drop inhibits enzymatic activity and moisture loss, resulting in superior texture retention and enhanced product quality.

Cryogenic Tenderization Index

Cryogenic chilling significantly enhances texture retention compared to blanching by maintaining a higher Cryogenic Tenderization Index, which measures the preservation of muscle fiber integrity during cooling. This advanced method minimizes cellular damage and moisture loss, resulting in a firmer, more tender texture ideal for high-quality meat processing.

Blanching vs Cryogenic chilling for texture retention. Infographic

cookingdiff.com

cookingdiff.com