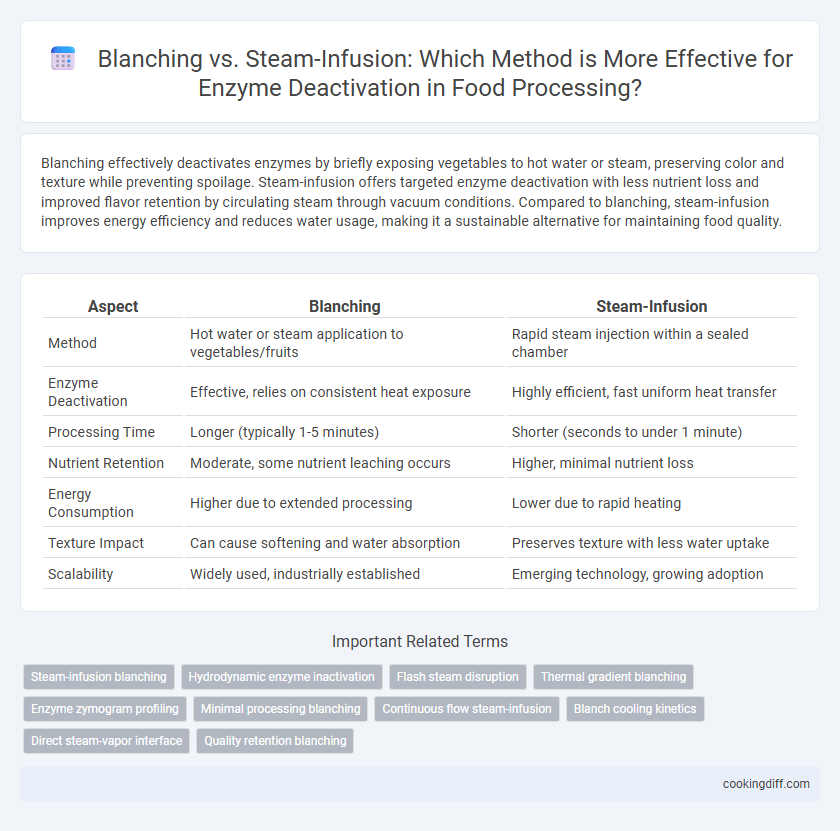

Blanching effectively deactivates enzymes by briefly exposing vegetables to hot water or steam, preserving color and texture while preventing spoilage. Steam-infusion offers targeted enzyme deactivation with less nutrient loss and improved flavor retention by circulating steam through vacuum conditions. Compared to blanching, steam-infusion improves energy efficiency and reduces water usage, making it a sustainable alternative for maintaining food quality.

Table of Comparison

| Aspect | Blanching | Steam-Infusion |

|---|---|---|

| Method | Hot water or steam application to vegetables/fruits | Rapid steam injection within a sealed chamber |

| Enzyme Deactivation | Effective, relies on consistent heat exposure | Highly efficient, fast uniform heat transfer |

| Processing Time | Longer (typically 1-5 minutes) | Shorter (seconds to under 1 minute) |

| Nutrient Retention | Moderate, some nutrient leaching occurs | Higher, minimal nutrient loss |

| Energy Consumption | Higher due to extended processing | Lower due to rapid heating |

| Texture Impact | Can cause softening and water absorption | Preserves texture with less water uptake |

| Scalability | Widely used, industrially established | Emerging technology, growing adoption |

Introduction to Enzyme Deactivation in Cooking

Enzyme deactivation is a critical step in cooking to preserve food quality by halting enzymatic reactions that lead to spoilage and nutrient loss. Blanching and steam-infusion are two effective methods employed to inactivate enzymes, each with unique mechanisms and efficiency levels.

- Blanching - Involves immersing food briefly in boiling water to rapidly deactivate enzymes and preserve color, texture, and flavor.

- Steam-infusion - Utilizes high-velocity steam to penetrate food quickly, providing uniform heating and enzyme deactivation with less water use.

- Enzyme deactivation - Essential to maintain shelf life, nutritional value, and sensory attributes in processed foods through thermal treatments.

Understanding Blanching: Process and Purpose

Blanching involves briefly exposing vegetables or fruits to boiling water or steam to deactivate enzymes that cause spoilage, ensuring prolonged freshness and color retention. This thermal process effectively halts enzymatic reactions by denaturing enzymes such as polyphenol oxidase and peroxidase, which are responsible for degradation. Steam-infusion, as an alternative, uses direct steam injection to rapidly and uniformly increase product temperature, offering faster enzyme deactivation with reduced nutrient loss compared to traditional blanching methods.

What Is Steam-Infusion? A Modern Approach

Steam-infusion is a modern thermal processing technique that rapidly heats food products by directly injecting them into a chamber filled with hot steam, ensuring uniform temperature distribution. This method significantly reduces processing time compared to traditional blanching, preserving more nutrients and enhancing enzyme deactivation efficiency.

Unlike conventional blanching, which relies on hot water or steam exposure, steam-infusion minimizes product moisture gain and thermal degradation. Its precise temperature control leads to consistent enzyme inactivation, improving food quality and shelf life in industrial applications.

Mechanisms of Enzyme Deactivation: Blanching vs Steam-Infusion

How do blanching and steam-infusion differ in their mechanisms of enzyme deactivation? Blanching uses hot water or steam to rapidly raise the temperature, disrupting enzyme structure and halting enzymatic activity through denaturation. Steam-infusion injects steam directly into the product, causing rapid and uniform heating that inactivates enzymes more quickly and with less thermal damage to nutrients compared to traditional blanching.

Effectiveness in Preserving Nutritional Value

Blanching effectively deactivates enzymes but can cause significant nutrient loss due to prolonged exposure to hot water. Steam-infusion offers rapid enzyme deactivation with better retention of vitamins and antioxidants by minimizing heat exposure time.

- Blanching - Uses hot water immersion that can leach water-soluble nutrients like vitamin C and B vitamins.

- Steam-infusion - Employs steam under pressure to penetrate food quickly, reducing nutrient degradation.

- Nutrient Preservation - Steam-infusion better maintains antioxidant levels and overall nutritional quality compared to traditional blanching.

Steam-infusion presents a superior method for enzyme deactivation while enhancing the preservation of essential nutrients in food processing.

Impact on Color, Texture, and Flavor Retention

Blanching effectively deactivates enzymes to preserve food quality, but may cause slight color fading and texture softening. Steam-infusion offers more rapid enzyme inactivation with superior retention of vivid color, firmer texture, and fresher flavor profiles.

- Color Retention - Steam-infusion minimizes pigment degradation, maintaining brighter, more vibrant hues compared to conventional blanching.

- Texture Preservation - The rapid heat transfer in steam-infusion reduces cell damage, resulting in crisper and firmer food texture.

- Flavor Maintenance - Steam-infusion limits flavor leaching and oxidation, better preserving natural aromatic compounds than traditional blanching.

Energy and Water Consumption Comparison

Blanching typically requires higher water usage and energy consumption due to prolonged boiling periods to achieve enzyme deactivation. Steam-infusion offers a more energy-efficient alternative by rapidly increasing product temperature with minimal water use.

Energy efficiency in steam-infusion results from direct steam contact, reducing heat loss compared to traditional blanching baths. Water consumption is significantly lower in steam-infusion processes, supporting sustainability goals in food processing. These benefits make steam-infusion a preferable method for enzyme deactivation when optimizing resource use is prioritized.

Suitability for Different Food Types

Blanching is highly effective for a wide range of vegetables, especially leafy greens and root crops, as it rapidly deactivates enzymes and preserves color and texture. Steam-infusion offers precise temperature control and uniform heating, making it suitable for delicate fruits and soft vegetables that are sensitive to water exposure.

Vegetables with thick skins or dense tissues respond well to traditional blanching due to its penetration depth, ensuring thorough enzyme deactivation. Conversely, steam-infusion excels in maintaining nutritional quality and sensory attributes in foods prone to water leaching, such as berries and tender produce.

Equipment and Practical Considerations

| Equipment Requirements | Blanching typically requires large water baths or continuous tunnel systems with precise temperature control, whereas steam-infusion systems use specialized chambers that introduce steam directly to the product, allowing for rapid temperature elevation. |

|---|---|

| Energy Efficiency | Steam-infusion generally offers higher energy efficiency by reducing heating times and minimizing water usage compared to traditional blanching, which consumes significant water and energy for maintaining hot water reservoirs. |

| Operational Practicalities | Blanching equipment demands regular maintenance due to scaling and water quality issues, while steam-infusion systems require meticulous calibration to ensure uniform steam distribution and consistent enzyme deactivation across variable product matrices. |

Related Important Terms

Steam-infusion blanching

Steam-infusion blanching offers rapid and uniform enzyme deactivation by directly injecting steam into the product, minimizing nutrient loss and preserving texture better than conventional blanching methods. This technique enhances heat transfer efficiency, reducing processing time and energy consumption while maintaining product quality.

Hydrodynamic enzyme inactivation

Blanching uses hot water or steam to disrupt enzyme activity by heat transfer, but steam-infusion employs rapid hydrodynamic shear forces and direct steam injection for more efficient and uniform enzyme deactivation. Hydrodynamic enzyme inactivation in steam-infusion results in faster temperature rise and enhanced preservation of product quality compared to traditional blanching methods.

Flash steam disruption

Flash steam disruption in blanching rapidly deactivates enzymes by exposing vegetables to high-temperature steam for a brief period, preserving color and texture better than conventional methods. Steam-infusion offers a controlled environment for enzyme inactivation, but flash steam disruption achieves faster thermal penetration, reducing nutrient loss and processing time.

Thermal gradient blanching

Thermal gradient blanching utilizes a controlled temperature difference to rapidly inactivate enzymes, preserving color and texture more effectively than traditional blanching methods. Compared to steam-infusion, thermal gradient blanching ensures uniform heat distribution, reducing nutrient loss and enhancing overall product quality during enzyme deactivation.

Enzyme zymogram profiling

Blanching effectively inactivates enzymes through high-temperature exposure, resulting in distinct changes observable in enzyme zymogram profiling, with clear reductions in isoenzyme bands indicating successful enzyme deactivation. Steam-infusion offers rapid heat transfer and uniform temperature distribution, which can preserve enzyme structures differently, reflected by varied enzyme activity patterns and zymogram profiles compared to traditional blanching methods.

Minimal processing blanching

Minimal processing blanching uses controlled heat and time to effectively deactivate enzymes while preserving nutritional quality and texture, contrasting with steam-infusion which relies on rapid steam exposure for enzyme inactivation but may cause uneven heat distribution. Studies show minimal processing blanching ensures more consistent enzyme deactivation with reduced nutrient degradation compared to steam-infusion methods.

Continuous flow steam-infusion

Continuous flow steam-infusion offers rapid and uniform enzyme deactivation by directly injecting steam into the product, preserving nutrients and texture more effectively than traditional blanching methods. This process reduces processing time and energy consumption while maintaining product quality in industrial food applications.

Blanch cooling kinetics

Blanch cooling kinetics significantly influence enzyme deactivation efficacy by rapidly lowering product temperature to inhibit residual enzyme activity, ensuring microbial safety and quality retention. Compared to steam-infusion, blanching provides controlled cooling rates critical for minimizing thermal damage while optimizing enzyme inactivation in food processing.

Direct steam-vapor interface

Blanching utilizes hot water or steam to inactivate enzymes, but steam-infusion creates a direct steam-vapor interface that enables faster heat transfer and more uniform enzyme deactivation. This direct contact with steam vapor reduces processing time and preserves nutritional quality compared to traditional blanching methods.

Blanching vs Steam-infusion for enzyme deactivation. Infographic

cookingdiff.com

cookingdiff.com