Blanching involves briefly immersing food in boiling water or steam to inactivate enzymes and prepare it for freezing, while rapid thermal cycling uses alternating heating and cooling to achieve similar pre-cooking effects more efficiently. Rapid thermal cycling offers better retention of texture, flavor, and nutrients compared to traditional blanching by minimizing overcooking and moisture loss. Both methods aid in shelf life extension, but rapid thermal cycling is often favored for its energy efficiency and superior product quality.

Table of Comparison

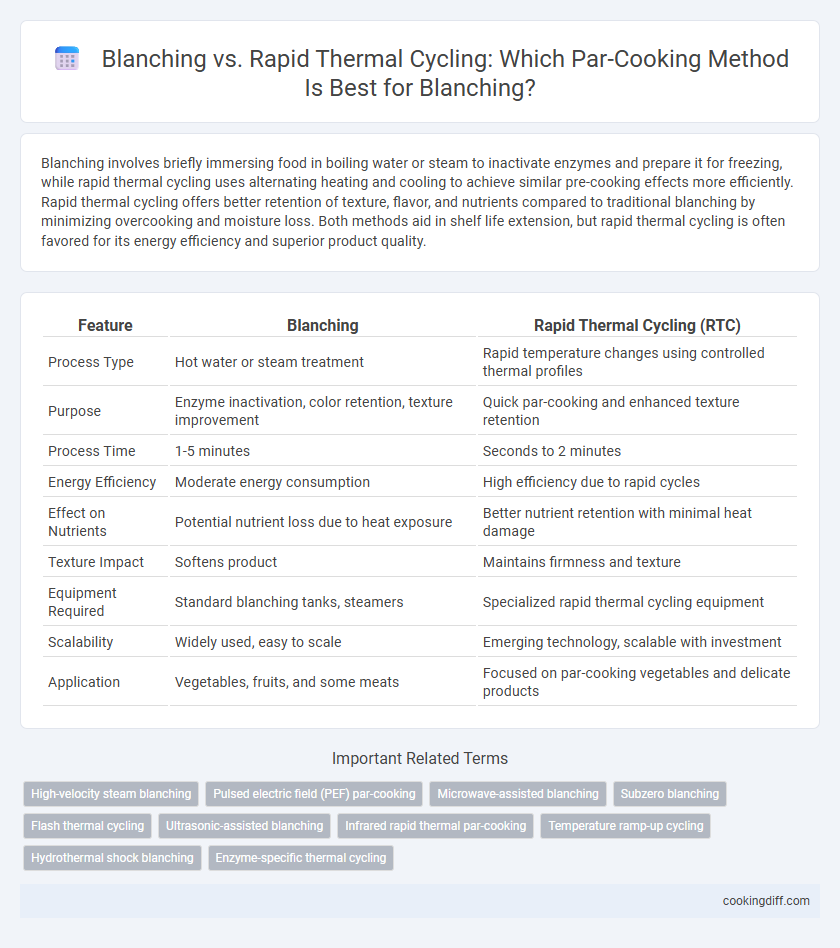

| Feature | Blanching | Rapid Thermal Cycling (RTC) |

|---|---|---|

| Process Type | Hot water or steam treatment | Rapid temperature changes using controlled thermal profiles |

| Purpose | Enzyme inactivation, color retention, texture improvement | Quick par-cooking and enhanced texture retention |

| Process Time | 1-5 minutes | Seconds to 2 minutes |

| Energy Efficiency | Moderate energy consumption | High efficiency due to rapid cycles |

| Effect on Nutrients | Potential nutrient loss due to heat exposure | Better nutrient retention with minimal heat damage |

| Texture Impact | Softens product | Maintains firmness and texture |

| Equipment Required | Standard blanching tanks, steamers | Specialized rapid thermal cycling equipment |

| Scalability | Widely used, easy to scale | Emerging technology, scalable with investment |

| Application | Vegetables, fruits, and some meats | Focused on par-cooking vegetables and delicate products |

Introduction to Par-Cooking Methods

Par-cooking methods like blanching and rapid thermal cycling are essential for partially cooking food to preserve texture and flavor. These techniques prepare ingredients for final cooking stages while maintaining quality and safety.

- Blanching - Involves briefly boiling food and then cooling it rapidly to halt enzymatic activity and retain color and texture.

- Rapid Thermal Cycling - Uses quick temperature changes to partially cook food, minimizing nutrient loss and improving shelf life.

- Par-Cooking Purpose - Both methods aim to reduce cooking time later while preserving the physical and sensory properties of food.

Choosing the appropriate par-cooking method depends on the food type and desired quality outcomes.

What is Blanching?

Blanching is a food processing technique involving brief exposure of vegetables or fruits to boiling water or steam, followed by rapid cooling. This process helps inactivating enzymes that cause spoilage, preserving color, texture, and nutritional value.

Blanching is commonly used as a pre-treatment before freezing or drying to maintain food quality. It differs from rapid thermal cycling, which alternates temperature quickly to achieve par-cooking with minimal texture and flavor loss. While blanching primarily controls enzymes and microorganisms, rapid thermal cycling focuses on precise temperature control for faster cooking times.

Understanding Rapid Thermal Cycling

Rapid Thermal Cycling (RTC) offers precise temperature control for par-cooking, reducing nutrient loss compared to traditional blanching. RTC cycles food through rapid heating and cooling phases, preserving texture and flavor more effectively.

- Temperature control - RTC uses rapid fluctuations between high and low temperatures to minimize overcooking.

- Nutrient retention - Faster cycling reduces leaching of vitamins and minerals typical in conventional blanching.

- Texture preservation - Quick transitions help maintain firmness and prevent mushiness in vegetables.

Key Differences Between Blanching and Rapid Thermal Cycling

Blanching involves briefly immersing food in hot water or steam to inactivate enzymes and preserve color, flavor, and texture. Rapid thermal cycling (RTC) uses alternating temperature phases to partially cook food with precise control over thermal exposure.

Blanching is a traditional method focused on enzyme deactivation and surface heating, often leading to nutrient loss due to water contact. RTC offers improved retention of nutrients and texture by minimizing cooking time and avoiding prolonged exposure to high temperatures.

Effects on Nutrient Retention

Blanching causes partial nutrient loss due to heat-sensitive vitamins leaching into the water, particularly vitamin C and B-complex vitamins. However, it inactivates enzymes that may degrade nutrients, helping preserve overall nutritional quality during storage.

Rapid thermal cycling for par-cooking minimizes nutrient degradation by reducing exposure time to high temperatures and limiting nutrient leaching. This method better retains antioxidants and vitamins compared to traditional blanching, improving the nutritional profile of cooked vegetables.

Impact on Flavor and Texture

Blanching preserves brightness and texture by inactivating enzymes and softening cell walls, resulting in a milder impact on flavor compared to rapid thermal cycling. Rapid thermal cycling, with its quick temperature changes, can enhance flavor development through Maillard reactions but may cause uneven texture due to thermal stress. The choice between blanching and rapid thermal cycling influences product quality, balancing between retaining natural taste and achieving desired texture in par-cooked foods.

Efficiency and Time Comparison

| Blanching | Typically requires 2-5 minutes depending on the vegetable, involving hot water or steam to inactivate enzymes and preserve color and texture. |

| Rapid Thermal Cycling (RTC) | Par-cooks food within 30-90 seconds by alternating temperature rapidly, significantly reducing cooking time and improving energy efficiency. |

| Efficiency Comparison | RTC consumes up to 40% less energy due to shorter cooking cycles, while blanching uses prolonged heat exposure, increasing energy and water consumption. |

| Time Comparison | RTC decreases total processing time by up to 70%, enhancing throughput in commercial kitchens compared to traditional blanching methods. |

Equipment Needed for Each Method

Blanching requires basic steam or hot water baths to rapidly heat food items for short durations, while rapid thermal cycling utilizes advanced equipment capable of precise temperature control through rapid heating and cooling phases. The choice of equipment impacts energy efficiency, processing time, and final product texture during par-cooking.

- Blanching equipment - Includes steamers or hot water tanks designed to maintain consistent high temperatures for uniform heat transfer.

- Rapid thermal cycling equipment - Involves programmable ovens or thermal chambers with sensors for rapid temperature fluctuations and controlled cycling.

- Control systems - Blanching systems often use manual or simple timer controls; rapid thermal cycling requires sophisticated digital controllers for accurate thermal profiles.

Common Applications in Modern Cooking

How do blanching and rapid thermal cycling compare in par-cooking applications? Blanching is commonly used in modern kitchens to preserve color and texture in vegetables before freezing. Rapid thermal cycling offers precise temperature control, making it ideal for maintaining food safety and quality in ready-to-eat meals.

Related Important Terms

High-velocity steam blanching

High-velocity steam blanching enhances par-cooking by delivering rapid heat transfer that preserves nutrient integrity and reduces enzymatic activity more effectively than traditional blanching methods. Compared to rapid thermal cycling, it offers superior process control and energy efficiency, ensuring minimal texture degradation and improved product quality.

Pulsed electric field (PEF) par-cooking

Pulsed Electric Field (PEF) par-cooking offers a non-thermal alternative to traditional blanching by enhancing cell membrane permeability, leading to faster heat transfer and improved product texture compared to rapid thermal cycling. PEF treatment reduces nutrient loss and energy consumption while maintaining quality attributes, making it a promising technology for efficient pre-cooking processes.

Microwave-assisted blanching

Microwave-assisted blanching offers precise control over temperature and time, reducing nutrient loss and enzymatic activity more effectively than traditional blanching methods. Compared to rapid thermal cycling, it enables uniform heating with shorter processing times, enhancing texture retention and overall quality in par-cooked products.

Subzero blanching

Subzero blanching enhances par-cooking efficiency by rapidly reducing surface temperatures below freezing, preserving texture and nutrients more effectively than traditional blanching or rapid thermal cycling. This method minimizes enzymatic activity and microbial load while maintaining the sensory qualities of vegetables compared to higher temperature par-cooking techniques.

Flash thermal cycling

Flash thermal cycling offers a precise, rapid temperature control method for par-cooking that significantly reduces nutrient loss and texture degradation compared to traditional blanching. This technique accelerates the heat transfer process, improving cooking uniformity while preserving color, flavor, and essential vitamins in vegetables.

Ultrasonic-assisted blanching

Ultrasonic-assisted blanching enhances nutrient retention and reduces processing time compared to traditional blanching methods, offering superior quality in par-cooked foods. When compared to rapid thermal cycling, ultrasonic-assisted blanching provides more uniform heat distribution and minimizes thermal damage, improving texture and shelf life.

Infrared rapid thermal par-cooking

Infrared rapid thermal par-cooking offers a more efficient heat transfer method compared to traditional blanching, reducing cooking time while preserving nutrients and texture. This technique uses infrared radiation to quickly elevate product temperature, minimizing moisture loss and enhancing energy efficiency in industrial food processing.

Temperature ramp-up cycling

Blanching typically involves a gradual temperature ramp-up to inactivate enzymes and preserve food quality, while rapid thermal cycling employs swift temperature changes to achieve faster par-cooking and improved texture retention. The precise control of temperature ramp-up in rapid thermal cycling enhances nutrient preservation and reduces cooking time compared to conventional blanching methods.

Hydrothermal shock blanching

Hydrothermal shock blanching induces rapid temperature changes that enhance enzyme inactivation and microbial control more effectively than conventional blanching by causing thermal stress at the cellular level. Compared to rapid thermal cycling, hydrothermal shock blanching offers improved texture retention and nutrient preservation during par-cooking processes.

Blanching vs Rapid thermal cycling for par-cooking. Infographic

cookingdiff.com

cookingdiff.com