Blanching involves briefly boiling vegetables to inactivate enzymes, which can cause some flavor loss due to heat exposure and leaching into the water. Vacuum infusion preserves flavor more effectively by using low pressure to infuse flavors directly into the food without high-temperature processing, minimizing nutrient and taste degradation. While blanching is efficient for enzyme control, vacuum infusion offers superior retention of fresh, vibrant flavors.

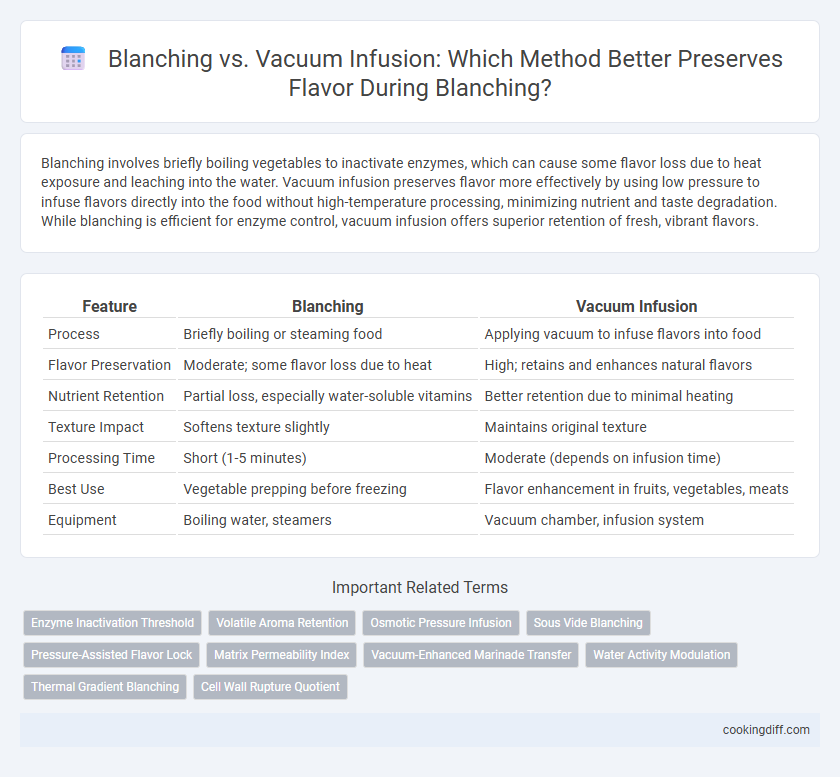

Table of Comparison

| Feature | Blanching | Vacuum Infusion |

|---|---|---|

| Process | Briefly boiling or steaming food | Applying vacuum to infuse flavors into food |

| Flavor Preservation | Moderate; some flavor loss due to heat | High; retains and enhances natural flavors |

| Nutrient Retention | Partial loss, especially water-soluble vitamins | Better retention due to minimal heating |

| Texture Impact | Softens texture slightly | Maintains original texture |

| Processing Time | Short (1-5 minutes) | Moderate (depends on infusion time) |

| Best Use | Vegetable prepping before freezing | Flavor enhancement in fruits, vegetables, meats |

| Equipment | Boiling water, steamers | Vacuum chamber, infusion system |

Introduction to Blanching and Vacuum Infusion

Blanching is a heat treatment process that quickly scalds food to halt enzyme actions, preserving color and flavor. Vacuum infusion uses reduced pressure to enhance flavor absorption by forcing liquids into the food's pores, offering a more controlled infusion.

- Blanching involves brief exposure to boiling water or steam - This process inactivates enzymes that cause spoilage and flavor degradation.

- Vacuum infusion applies low pressure to open food structure pores - This allows for deeper and more consistent flavor penetration without heat damage.

- Both methods prioritize flavor preservation but differ in technique - Blanching uses heat to stabilize flavor, while vacuum infusion enhances flavor by physical pressure changes.

Understanding the Science Behind Flavor Preservation

Blanching rapidly heats food to deactivate enzymes responsible for flavor degradation, whereas vacuum infusion uses pressure differences to infuse flavors without heat. Understanding enzyme inactivation and mass transfer principles is crucial for optimizing flavor preservation in both methods.

- Enzyme Inactivation - Blanching denatures enzymes like polyphenol oxidase, preventing off-flavors and spoilage.

- Mass Transfer Efficiency - Vacuum infusion enhances flavor penetration by creating pressure gradients that drive liquids into food tissues.

- Heat Sensitivity - Blanching's thermal process can alter volatile compounds, while vacuum infusion preserves volatile flavors by avoiding heat.

Choosing between blanching and vacuum infusion depends on balancing enzymatic control with flavor retention goals.

How Blanching Works to Preserve Flavor

Blanching preserves flavor by rapidly heating food in boiling water or steam, which deactivates enzymes responsible for flavor degradation and nutrient loss. This process effectively halts enzymatic activity without cooking the food fully, maintaining its original taste and texture.

Compared to vacuum infusion, blanching uses thermal treatment to stabilize flavor compounds quickly, whereas vacuum infusion introduces flavors by forcing liquids into the food under reduced pressure. Consequently, blanching primarily preserves natural flavors by preventing spoilage, while vacuum infusion enhances flavor by adding external elements.

The Process of Vacuum Infusion Explained

| Vacuum Infusion Process | Vacuum infusion involves placing food in a vacuum chamber where air is removed to create low pressure, allowing flavoring liquids to penetrate the food's cellular structure rapidly and deeply. |

| Flavor Preservation | The low pressure environment minimizes nutrient loss and preserves volatile aroma compounds better than blanching, which typically exposes food to heat and water, causing flavor dilution and degradation. |

| Comparison to Blanching | Unlike blanching where food undergoes brief heat treatment, vacuum infusion avoids thermal stress, resulting in enhanced flavor retention and texture maintenance, making it preferable for delicate ingredients. |

Key Differences Between Blanching and Vacuum Infusion

Blanching involves briefly boiling or steaming food to inactivate enzymes, preserving color and texture, whereas vacuum infusion uses reduced pressure to enhance flavor absorption by forcing liquids into food pores. Blanching primarily targets enzyme deactivation, while vacuum infusion focuses on flavor enhancement and uniform seasoning.

The key difference lies in their purpose: blanching is a thermal process that stabilizes food quality by halting enzymatic activity, and vacuum infusion is a mechanical process improving flavor penetration without heat. Blanching can cause some nutrient loss, while vacuum infusion maintains nutritional content while intensifying taste. Both techniques are valuable in food processing but serve distinct roles in flavor preservation and food texture management.

Impact on Texture and Color: Blanching vs Vacuum Infusion

Blanching rapidly heats food, causing partial gelatinization of starches and cell wall softening, which can lead to texture changes such as slight mushiness and color fading due to pigment degradation. Vacuum infusion preserves texture by infusing flavors under low pressure, maintaining cell integrity and vibrant color better than blanching. Studies show vacuum infusion retains up to 90% of natural color compounds compared to 70% in blanching, enhancing visual appeal and mouthfeel.

Nutrient Retention in Blanching vs Vacuum Infusion

Blanching involves briefly scalding vegetables in boiling water or steam to inactivate enzymes, which can cause some loss of water-soluble nutrients like vitamin C and B vitamins. However, this process helps preserve color and texture, indirectly maintaining nutrient quality by slowing degradation.

Vacuum infusion enhances flavor by forcing liquid solutions into plant tissues under reduced pressure, minimizing nutrient leaching and preserving heat-sensitive vitamins more effectively than blanching. This method retains higher levels of antioxidants and water-soluble vitamins due to the absence of high-temperature exposure during the infusion process.

Practical Applications in Home and Professional Kitchens

Blanching rapidly preserves vegetable color and texture by briefly boiling then shocking in ice water, ideal for home kitchens to maintain freshness. Vacuum infusion enhances flavor by using a vacuum to draw marinades deep into foods, preferred in professional kitchens for complex taste development.

- Blanching in Home Cooking - Quickly preserves nutrient content and bright color, making vegetables ready for freezing or immediate use.

- Vacuum Infusion in Professional Kitchens - Allows chefs to infuse robust flavors efficiently, improving consistency and depth in culinary creations.

- Equipment Requirements - Blanching needs only a pot and ice bath, while vacuum infusion requires specialized vacuum chambers for optimal results.

Pros and Cons of Blanching for Flavor Preservation

How effective is blanching for flavor preservation compared to other methods? Blanching helps inactivating enzymes that cause flavor degradation but may also lead to the loss of volatile flavor compounds due to heat exposure. This process is quick and cost-effective but can result in a less vibrant taste compared to vacuum infusion, which better retains natural flavors by minimizing heat damage.

Related Important Terms

Enzyme Inactivation Threshold

Blanching effectively preserves flavor by rapidly heating food to reach enzyme inactivation thresholds, typically between 70-90degC, which halts enzymatic activity responsible for flavor degradation. In contrast, vacuum infusion may enhance flavor absorption but does not consistently achieve the critical temperature needed for full enzyme inactivation, potentially allowing flavor loss over time.

Volatile Aroma Retention

Blanching often results in significant loss of volatile aroma compounds due to heat exposure, leading to diminished flavor intensity in treated foods. Vacuum infusion preserves volatile aroma retention more effectively by minimizing thermal degradation and maintaining the integrity of flavor compounds during processing.

Osmotic Pressure Infusion

Osmotic pressure infusion in vacuum infusion methods enhances flavor preservation by driving solutes into food tissues more effectively than blanching, which primarily uses heat to inactivate enzymes but can cause flavor loss. This controlled infusion process maintains the product's texture and nutritional quality while achieving superior flavor retention compared to traditional thermal blanching.

Sous Vide Blanching

Sous vide blanching precisely controls temperature and time to preserve cellular integrity and volatile flavor compounds better than traditional blanching or vacuum infusion methods. This technique minimizes nutrient loss while enhancing flavor retention by preventing overcooking and oxidation during the blanching process.

Pressure-Assisted Flavor Lock

Pressure-assisted flavor lock in vacuum infusion preserves volatile compounds more effectively than traditional blanching by minimizing heat exposure and preventing flavor loss during processing. This technique maintains the natural aroma and taste profiles of ingredients, ensuring superior flavor retention in food products.

Matrix Permeability Index

Blanching typically reduces the matrix permeability index by causing cell wall degradation, which diminishes flavor retention in food products. Vacuum infusion enhances matrix permeability without extensive cell damage, allowing better penetration of flavor compounds and superior flavor preservation compared to blanching.

Vacuum-Enhanced Marinade Transfer

Vacuum-enhanced marinade transfer significantly improves flavor preservation by accelerating the infusion of marinades into food, creating deeper and more uniform seasoning compared to traditional blanching. Unlike blanching, which primarily uses heat and water to partially cook and preserve food, vacuum infusion maintains food texture and enhances flavor absorption without nutrient loss.

Water Activity Modulation

Blanching reduces water activity by applying heat to deactivate enzymes and remove surface microbes, which helps preserve flavor by inhibiting spoilage reactions. Vacuum infusion modulates water activity by introducing flavor-infused solutions under reduced pressure, enhancing flavor retention without the thermal impact that can alter delicate compounds.

Thermal Gradient Blanching

Thermal Gradient Blanching uses controlled temperature differentials to rapidly inactivate enzymes while minimizing nutrient and flavor loss, offering superior preservation compared to Vacuum Infusion, which relies on pressure changes that may cause flavor dilution. This precise thermal control enhances retention of volatile aromatic compounds and maintains textural integrity, making it an effective method for preserving fresh flavor profiles in processed foods.

Blanching vs Vacuum Infusion for flavor preservation. Infographic

cookingdiff.com

cookingdiff.com