An ice bath bowl is ideal for small-scale blanching, offering precise temperature control and quick cooling to preserve texture and color. A shock tub provides a larger capacity suited for bulk processing, enabling efficient heat removal for multiple items simultaneously. Choosing between the two depends on the volume of blanching and the desired speed of cooling to maintain optimal pet food quality.

Table of Comparison

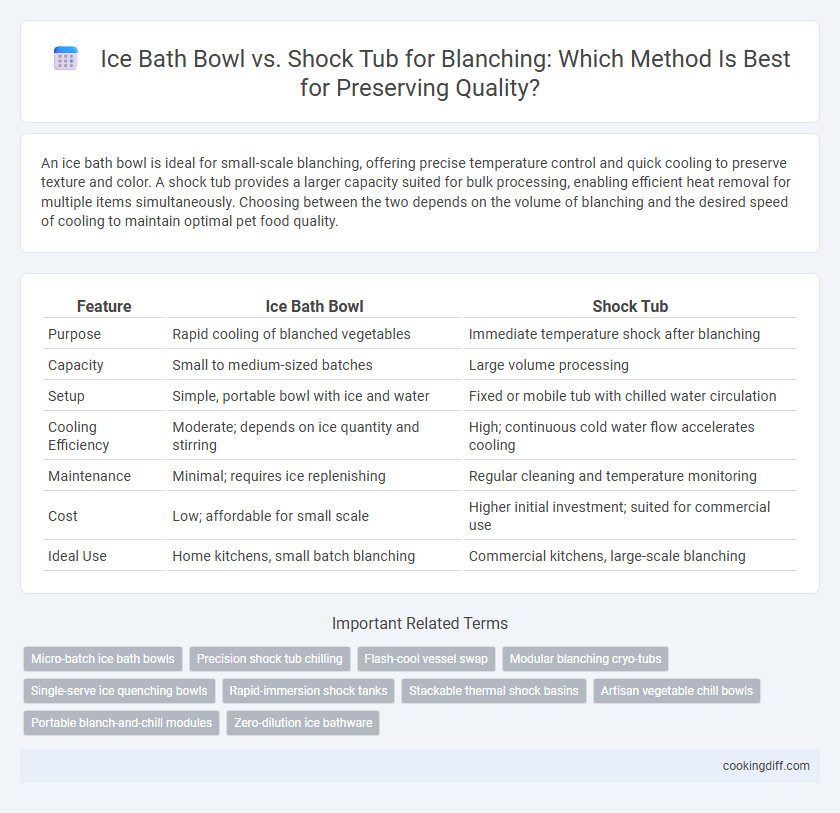

| Feature | Ice Bath Bowl | Shock Tub |

|---|---|---|

| Purpose | Rapid cooling of blanched vegetables | Immediate temperature shock after blanching |

| Capacity | Small to medium-sized batches | Large volume processing |

| Setup | Simple, portable bowl with ice and water | Fixed or mobile tub with chilled water circulation |

| Cooling Efficiency | Moderate; depends on ice quantity and stirring | High; continuous cold water flow accelerates cooling |

| Maintenance | Minimal; requires ice replenishing | Regular cleaning and temperature monitoring |

| Cost | Low; affordable for small scale | Higher initial investment; suited for commercial use |

| Ideal Use | Home kitchens, small batch blanching | Commercial kitchens, large-scale blanching |

Introduction: The Role of Cooling in Blanching

Cooling is a critical phase in the blanching process to halt enzyme activity and preserve vegetable texture and color. Efficient cooling prevents overcooking and maintains nutritional quality.

Ice bath bowls provide immediate temperature reduction by submerging vegetables in chilled water, ensuring rapid enzyme deactivation. Shock tubs, designed with larger capacities and continuous water circulation, offer consistent cooling for bulk blanching operations. Choosing between an ice bath bowl and a shock tub depends on processing volume, with shock tubs ideal for commercial-scale blanching and ice bath bowls suited for small batches.

Ice Bath Bowl: Overview and Typical Uses

The ice bath bowl is commonly used in blanching to rapidly cool vegetables, preserving their color, texture, and nutritional value after boiling. Its compact size makes it ideal for small batches and home cooking environments where precise control is needed.

Typically made of durable plastic or stainless steel, the ice bath bowl is filled with ice and water to halt the cooking process immediately. This method is especially effective for items like green beans, broccoli, and asparagus, ensuring optimal crispness and freshness.

Shock Tub: Definition and Application Explained

A shock tub is a large container filled with iced water used to rapidly cool blanched vegetables, preserving texture and color. Unlike a typical ice bath bowl, a shock tub accommodates higher volumes, making it ideal for commercial or bulk blanching processes.

- Efficient Cooling - Shock tubs provide immediate temperature reduction to halt cooking, ensuring optimal vegetable quality.

- Capacity Advantage - The larger size of shock tubs allows blanching of substantial vegetable quantities simultaneously.

- Food Safety - Proper use of shock tubs reduces microbial activity and maintains freshness post-blanching.

Speed and Efficiency: Ice Bath Bowl vs Shock Tub

Ice bath bowls provide rapid cooling for small batches, allowing quick temperature reduction and preserving texture during blanching. Shock tubs offer greater capacity and faster overall processing for large quantities, improving workflow efficiency in commercial kitchens. Choosing between the two depends on batch size and desired cooling speed to optimize blanching results.

Water Volume and Temperature Control Comparison

Which offers better water volume and temperature control for blanching, an ice bath bowl or a shock tub? Ice bath bowls typically hold less water, making temperature control faster but limiting blanch capacity. Shock tubs provide larger water volumes, ensuring consistent temperature maintenance ideal for batch blanching processes.

Space, Storage, and Kitchen Practicality

Ice bath bowls are compact and ideal for kitchens with limited counter space, while shock tubs require more room due to their larger size. Storage is easier with ice bath bowls as they can be nested or stacked, whereas shock tubs typically need dedicated shelf or floor space.

- Space Efficiency - Ice bath bowls fit comfortably on most countertops, making them practical for small kitchens.

- Storage Convenience - Ice bath bowls nest inside each other, saving storage space compared to bulky shock tubs.

- Kitchen Practicality - Ice bath bowls are lightweight and portable, while shock tubs demand more preparation and cleaning time.

Cost Analysis: Setup and Maintenance

Ice bath bowls typically require lower initial investment and minimal maintenance, making them cost-effective for small-scale blanching operations. Shock tubs, while involving higher setup costs due to larger capacity and integrated chilling systems, offer long-term savings through improved efficiency and reduced labor. Evaluating the balance between upfront expenses and operational benefits is crucial for selecting the optimal blanching method based on production scale and budget.

Effect on Food Quality and Texture

Ice bath bowls cool blanched vegetables quickly, preserving vibrant color and crisp texture. Shock tubs provide rapid cooling but may cause uneven temperature distribution, impacting texture consistency.

- Ice bath bowls maintain food quality - Uniform cold temperature slows enzymatic activity, retaining freshness and nutrients.

- Shock tubs enhance cooling speed - Large volume and agitation expedite cooling but risk localized overcooling.

- Texture impact differs - Ice baths preserve firmness, while shock tubs may induce occasional sogginess.

Choosing between the two depends on balancing cooling efficiency with desired food texture outcomes.

Sustainability and Water Usage Considerations

| Ice Bath Bowl | Uses less water overall by recycling the ice and water mixture, reducing wastage and conserving resources. Ideal for small-scale blanching operations focused on minimizing environmental impact. Requires frequent replenishment of ice, which may increase energy consumption depending on ice production methods. |

| Shock Tub | Consumes larger volumes of water due to continuous flow systems, leading to higher water usage and less sustainability. Often integrated with water filtration and recirculation systems to mitigate environmental footprint. Suitable for large-scale blanching but demands infrastructure for efficient water management and reuse. |

Related Important Terms

Micro-batch ice bath bowls

Micro-batch ice bath bowls offer precise temperature control and reduced water usage compared to traditional shock tubs, making them ideal for small-scale blanching operations. Their compact design enhances efficiency by quickly halting the cooking process, preserving texture and color in delicate vegetables.

Precision shock tub chilling

Precision shock tubs provide consistent and controlled temperature regulation for blanching, ensuring rapid cooling and maintaining optimal texture and color of vegetables. Unlike ice bath bowls, shock tubs enable precise chilling cycles that improve product quality and reduce thermal stress during processing.

Flash-cool vessel swap

Ice bath bowls offer a compact solution for quick cooling but limit rapid temperature recovery during blanching, whereas shock tubs provide a larger volume of cold water, enabling faster heat dissipation and efficient flash-cool vessel swaps. Utilizing shock tubs enhances blanching throughput by minimizing temperature fluctuations and maintaining consistent food texture and color.

Modular blanching cryo-tubs

Modular blanching cryo-tubs offer precise temperature control and rapid cooling, outperforming traditional ice bath bowls in maintaining optimal blanching consistency and product quality. Compared to shock tubs, these modular systems provide scalable, energy-efficient solutions with enhanced sanitation features ideal for high-volume processing environments.

Single-serve ice quenching bowls

Single-serve ice quenching bowls provide precise temperature control and rapid cooling for blanching, minimizing texture and nutrient loss compared to larger shock tubs. Their compact design enhances efficiency in portion-sized processing, making them ideal for maintaining optimal food quality during ice bath cooling.

Rapid-immersion shock tanks

Rapid-immersion shock tanks ensure precise temperature control and uniform cooling during blanching, enhancing product quality by quickly halting the cooking process. Compared to ice bath bowls, these tanks offer greater capacity and efficiency for large-scale operations, reducing thermal variability and improving texture retention in vegetables.

Stackable thermal shock basins

Stackable thermal shock basins provide efficient blanching by maintaining consistent cold temperatures and maximizing space with their modular design, unlike traditional ice bath bowls that offer limited capacity and thermal retention. These basins enhance cooling speed and improve food quality by facilitating rapid and uniform thermal shock during the blanching process.

Artisan vegetable chill bowls

Artisan vegetable chill bowls designed for blanching provide precise temperature control and consistent chilling, enhancing the quality and texture of vegetables compared to traditional shock tubs. These bowls optimize ice bath efficiency by maintaining uniform cold temperatures, reducing nutrient loss and over-chilling during the blanching process.

Portable blanch-and-chill modules

Portable blanch-and-chill modules feature ice bath bowls that provide controlled cooling for small-scale blanching processes, enhancing nutrient retention and texture in vegetables. Shock tubs, often larger and more industrial, deliver rapid chilling by immersing produce in ice water to halt cooking instantly, optimizing food safety and quality in high-volume operations.

Ice bath bowl vs shock tub for blanching. Infographic

cookingdiff.com

cookingdiff.com