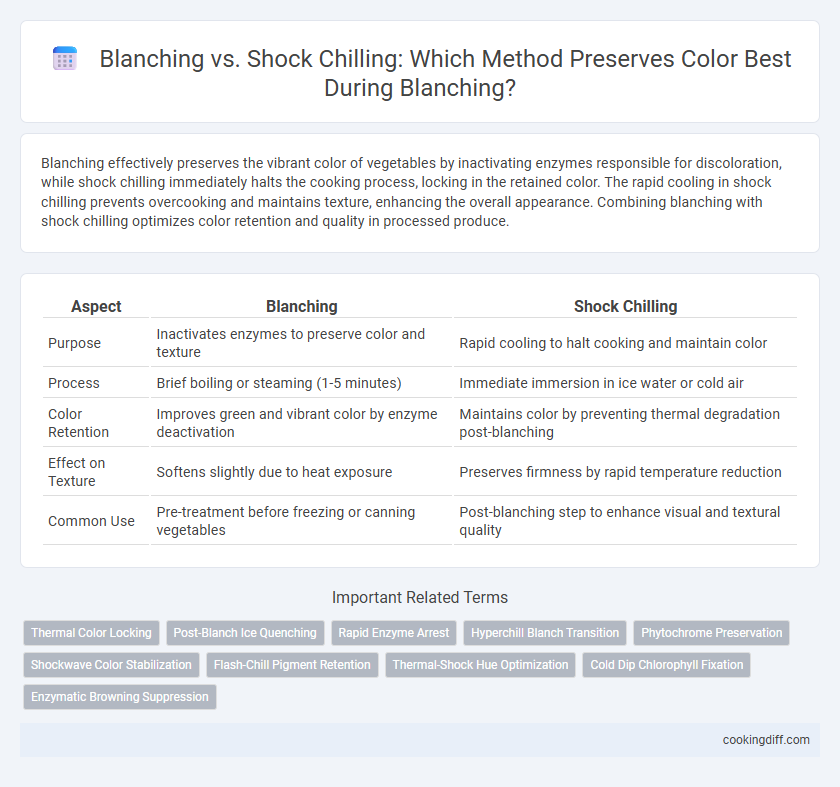

Blanching effectively preserves the vibrant color of vegetables by inactivating enzymes responsible for discoloration, while shock chilling immediately halts the cooking process, locking in the retained color. The rapid cooling in shock chilling prevents overcooking and maintains texture, enhancing the overall appearance. Combining blanching with shock chilling optimizes color retention and quality in processed produce.

Table of Comparison

| Aspect | Blanching | Shock Chilling |

|---|---|---|

| Purpose | Inactivates enzymes to preserve color and texture | Rapid cooling to halt cooking and maintain color |

| Process | Brief boiling or steaming (1-5 minutes) | Immediate immersion in ice water or cold air |

| Color Retention | Improves green and vibrant color by enzyme deactivation | Maintains color by preventing thermal degradation post-blanching |

| Effect on Texture | Softens slightly due to heat exposure | Preserves firmness by rapid temperature reduction |

| Common Use | Pre-treatment before freezing or canning vegetables | Post-blanching step to enhance visual and textural quality |

Introduction to Blanching and Shock Chilling

Blanching is a heat treatment process that involves briefly boiling vegetables to inactivate enzymes and preserve color, texture, and nutritional quality. Shock chilling, typically performed after blanching, rapidly cools the vegetables by immersing them in ice water to halt the cooking process and maintain vibrant color. Both methods are essential in industrial food processing for optimizing color retention and extending shelf life.

Science Behind Color Retention in Vegetables

Blanching inactivates enzymes like polyphenol oxidase and peroxidase responsible for color degradation in vegetables, preserving their chlorophyll and carotenoid pigments. Shock chilling rapidly lowers the temperature post-blanching, preventing further enzymatic activity and pigment breakdown while maintaining cellular structure. Studies demonstrate that the combination of blanching followed by shock chilling optimizes color retention by minimizing enzymatic browning and pigment leaching.

Blanching: Process and Benefits

Blanching involves briefly boiling vegetables followed by rapid cooling to halt enzyme activity and preserve vibrant color. This process enhances texture and nutritional value while extending shelf life by reducing microbial load.

Compared to shock chilling, blanching offers superior color retention by inactivating polyphenol oxidase enzymes responsible for browning. It is widely used in food processing to maintain freshness and visual appeal in frozen or canned products.

What is Shock Chilling?

Shock chilling rapidly cools blanched vegetables by immersing them in ice-cold water or using refrigerated air to stop the cooking process. This technique preserves the bright color, texture, and nutritional quality of vegetables better than slow cooling methods.

The immediate temperature drop caused by shock chilling prevents enzymatic reactions that lead to color degradation. Compared to traditional blanching followed by gradual cooling, shock chilling effectively retains the vibrant green and red pigments in vegetables like broccoli and bell peppers. This method is essential in commercial food processing to maintain product appeal and extend shelf life.

Comparing Blanching and Shock Chilling Methods

Blanching uses brief exposure to boiling water or steam to inactivate enzymes and preserve the vibrant color of vegetables. Shock chilling rapidly cools blanched vegetables in ice water to halt cooking and maintain color intensity.

- Blanching - Inactivates enzymatic activity to prevent discoloration in vegetables.

- Shock Chilling - Immediately stops the cooking process to retain bright colors and texture.

- Combined Effect - Blanching followed by shock chilling offers superior color retention compared to either method alone.

Factors Affecting Color Retention

How do blanching and shock chilling compare in terms of factors affecting color retention? Blanching deactivates enzymes responsible for color degradation, preserving the vibrant hues of vegetables more effectively. Shock chilling immediately halts the cooking process, locking in color by preventing overcooking and pigment breakdown.

Pros and Cons: Blanching vs Shock Chilling

Blanching enhances color retention by inactivating enzymes but may cause slight nutrient loss and texture softening. Shock chilling preserves vibrant color and crispness but requires rapid cooling equipment and is less effective at enzyme inactivation.

- Blanching improves color stability - Heat treatment deactivates oxidative enzymes that cause discoloration.

- Shock chilling maintains texture - Rapid cooling prevents overcooking and preserves firmness in vegetables.

- Blanching may reduce nutrients - Water or steam exposure can leach vitamins and minerals.

Best Practices for Maximum Color Preservation

Blanching involves briefly boiling vegetables to inactivate enzymes responsible for color degradation, effectively retaining vibrant hues. Shock chilling immediately after blanching rapidly cools produce, halting the cooking process and preserving color integrity.

Optimal color retention requires precise blanching time tailored to each vegetable to prevent overcooking or underprocessing. Combining rapid shock chilling with consistent blanching protocols maximizes pigment stability and enhances visual appeal in processed foods.

Common Mistakes in Blanching and Shock Chilling

| Common mistakes in blanching include over-blanching, which leads to nutrient loss and dull color, and under-blanching, resulting in incomplete enzyme inactivation and poor color retention. In shock chilling, improper timing or temperature control can cause thermal stress and water absorption, negatively affecting texture and color. Ensuring precise blanching time and immediate submersion in ice water is critical to maximize color retention and minimize degradation. |

Related Important Terms

Thermal Color Locking

Blanching uses brief hot-water or steam treatment to inactivate enzymes, effectively locking in color through thermal denaturation of oxidative enzymes, whereas shock chilling rapidly cools the product post-blanching to preserve this thermal color locking. The combined process of blanching followed by shock chilling maintains vibrant color by halting enzymatic browning and minimizing pigment degradation.

Post-Blanch Ice Quenching

Post-blanch ice quenching significantly enhances color retention by rapidly halting enzymatic activity that causes pigment degradation in vegetables. Compared to shock chilling, this rapid cooling method ensures vibrant color preservation by minimizing heat exposure and oxidative damage immediately after blanching.

Rapid Enzyme Arrest

Blanching rapidly arrests enzyme activity by subjecting vegetables to high-temperature steam or boiling water, effectively preserving their vibrant color and preventing enzymatic browning. Shock chilling immediately cools blanched produce in ice water, maintaining color retention and texture by halting the cooking process and locking in chlorophyll and carotenoids.

Hyperchill Blanch Transition

Hyperchill Blanch Transition enhances color retention by combining blanching's enzyme inactivation with shock chilling's rapid temperature drop, minimizing chlorophyll degradation. This process preserves vibrant vegetable hues better than traditional blanching or shock chilling alone, optimizing quality and shelf life.

Phytochrome Preservation

Blanching effectively inactivates enzymes that degrade phytochrome, thereby preserving the vibrant green color of vegetables by maintaining the chlorophyll structure. Shock chilling immediately after blanching halts the cooking process, further stabilizing phytochrome pigments and enhancing overall color retention during storage.

Shockwave Color Stabilization

Shockwave Color Stabilization during shock chilling enhances color retention by rapidly reducing product temperature, minimizing chlorophyll degradation and enzymatic browning compared to traditional blanching methods. This technique preserves vibrant green hues in vegetables by inhibiting pigment oxidation and maintaining cellular integrity more effectively.

Flash-Chill Pigment Retention

Flash-chill pigment retention preserves vibrant color by rapidly cooling blanched vegetables, inhibiting enzymatic oxidation and pigment degradation more effectively than traditional blanching alone. This technique maintains chlorophyll and anthocyanins, resulting in superior color stability in fresh and frozen produce.

Thermal-Shock Hue Optimization

Blanching uses brief exposure to hot water or steam to deactivate enzymes, preserving vibrant color by preventing oxidative browning, while shock chilling rapidly cools the product to halt the cooking process and lock in hue. Thermal-shock hue optimization combines precise temperature control during blanching with immediate cooling, maximizing color retention and maintaining visual appeal in fresh produce.

Cold Dip Chlorophyll Fixation

Blanching inactivates enzymes responsible for pigment degradation, preserving vibrant color by halting chlorophyll breakdown in vegetables, while shock chilling with a cold dip rapidly lowers temperature to fix chlorophyll and further enhance color retention. Cold dip chlorophyll fixation stabilizes the green pigments by preventing enzymatic and oxidative reactions, resulting in superior color preservation compared to blanching alone.

Blanching vs Shock Chilling for color retention. Infographic

cookingdiff.com

cookingdiff.com