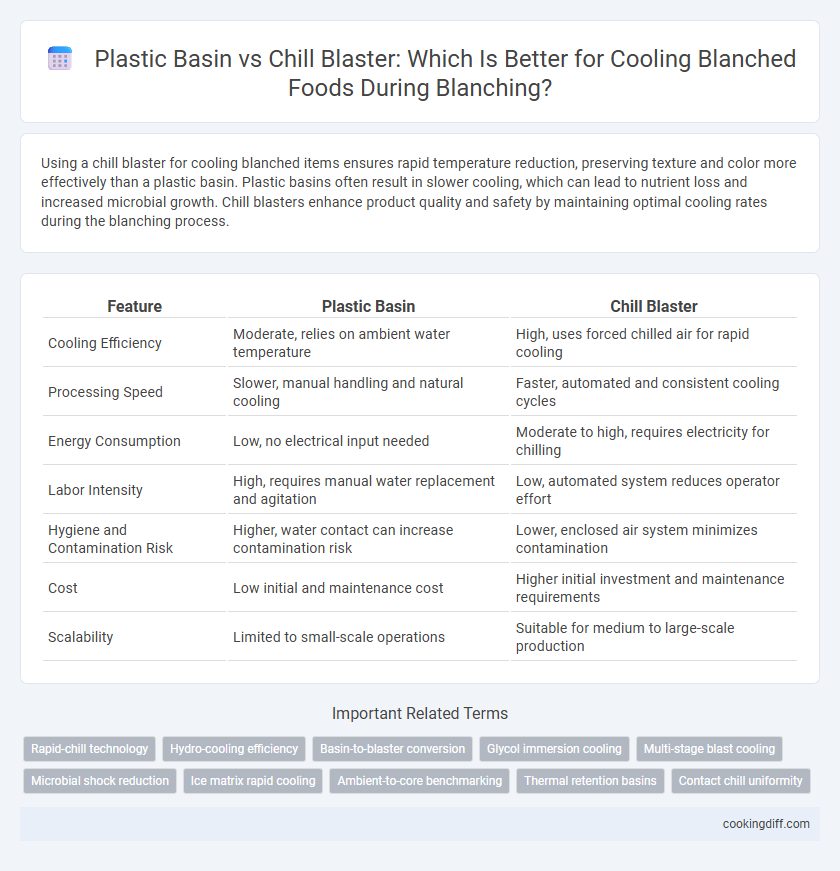

Using a chill blaster for cooling blanched items ensures rapid temperature reduction, preserving texture and color more effectively than a plastic basin. Plastic basins often result in slower cooling, which can lead to nutrient loss and increased microbial growth. Chill blasters enhance product quality and safety by maintaining optimal cooling rates during the blanching process.

Table of Comparison

| Feature | Plastic Basin | Chill Blaster |

|---|---|---|

| Cooling Efficiency | Moderate, relies on ambient water temperature | High, uses forced chilled air for rapid cooling |

| Processing Speed | Slower, manual handling and natural cooling | Faster, automated and consistent cooling cycles |

| Energy Consumption | Low, no electrical input needed | Moderate to high, requires electricity for chilling |

| Labor Intensity | High, requires manual water replacement and agitation | Low, automated system reduces operator effort |

| Hygiene and Contamination Risk | Higher, water contact can increase contamination risk | Lower, enclosed air system minimizes contamination |

| Cost | Low initial and maintenance cost | Higher initial investment and maintenance requirements |

| Scalability | Limited to small-scale operations | Suitable for medium to large-scale production |

Introduction: Cooling Blanched Foods Efficiently

Efficient cooling of blanched foods is critical to preserving texture and nutritional quality. Choosing the right cooling method impacts both food safety and processing speed.

- Plastic Basin Cooling - Provides a cost-effective and simple solution for small-scale operations by allowing gradual temperature reduction.

- Chill Blaster Cooling - Utilizes rapid chilled air circulation to drastically reduce cooling time and inhibit microbial growth.

- Heat Transfer Efficiency - Chill blasters offer superior heat extraction compared to plastic basins, enhancing overall cooling performance.

Optimizing cooling techniques ensures blanched foods maintain their quality and shelf life effectively.

The Basics of Blanching and Cooling

Blanching is a crucial step in food processing that involves briefly boiling vegetables and then rapidly cooling them to halt enzymatic activity. Cooling blanched items efficiently ensures texture, color, and nutrient retention, with plastic basins and chill blasters serving as common methods.

- Plastic Basin Cooling - Utilizes water at ambient or cold temperatures to gradually reduce the temperature of blanched items.

- Chill Blaster Cooling - Employs forced cold air or refrigerated systems to rapidly chill blanched products and prevent microbial growth.

- Cooling Efficiency - Chill blasters offer faster, more uniform cooling compared to plastic basins, reducing the risk of quality degradation.

Why Proper Cooling Matters After Blanching

Proper cooling after blanching halts the cooking process, preserving the texture and nutritional value of vegetables. Using a plastic basin often results in slower cooling, which can lead to overcooking and nutrient loss.

Chill blasters provide rapid cooling through forced chilled air, minimizing enzymatic activity and microbial growth. This efficient cooling method enhances food safety and extends shelf life of blanched items.

Overview: Plastic Basin vs. Chill Blaster

Plastic basins are commonly used for cooling blanched items by allowing natural air or water to reduce temperature gradually, which is energy-efficient but slower. Chill blasters employ powerful chilled air jets, providing rapid cooling that helps maintain texture and color by preventing overcooking.

Plastic basins are cost-effective and simple to operate but may risk microbial contamination if not properly sanitized. Chill blasters offer consistent temperature control and faster processing times, crucial for high-volume food processing environments aiming to maintain product quality.

Plastic Basin Method: Pros and Cons

The plastic basin method for cooling blanched items offers simplicity and low cost, making it accessible for small-scale operations. However, it often results in slower cooling rates, increasing the risk of bacterial growth and quality degradation.

Using a plastic basin allows for easy handling and minimal equipment investment, but it does not provide uniform cooling like the chill blaster method. The slower cooling process can lead to moisture retention, affecting texture and shelf life. Proper monitoring is essential to prevent overheating or undercooling when using this method.

Chill Blaster Technology: Pros and Cons

How does Chill Blaster technology compare to traditional plastic basins for cooling blanched items? Chill Blaster machines use high-velocity cold air to rapidly reduce the temperature of blanched products, preserving texture and nutritional quality more effectively than water cooling in plastic basins. However, Chill Blaster systems require higher initial investment and maintenance costs compared to the low-cost, simple design of plastic basins.

Speed and Temperature Control: A Comparative Analysis

Chill blasters offer rapid cooling of blanched items by utilizing high-velocity chilled air, achieving precise temperature control to prevent microbial growth and maintain product quality, whereas plastic basins rely on slower immersion cooling with less consistent temperature regulation. The speed of chill blasters significantly reduces cooling time, enhancing throughput in commercial food processing environments. Temperature consistency in chill blasters ensures uniform cooling, reducing the risk of over- or under-processing compared to the variable temperatures often encountered with plastic basins.

Food Safety Implications: Which Method Wins?

The Chill blaster offers superior food safety by rapidly lowering the temperature of blanched items, minimizing bacterial growth and contamination risks. Plastic basins, while convenient, often result in slower cooling times that can promote microbial proliferation and compromise food quality.

- Rapid Cooling with Chill Blaster - Quickly reduces product temperature, effectively inhibiting pathogen development.

- Slower Cooling in Plastic Basins - Extended time in warm water creates an environment favorable to harmful bacteria.

- Food Safety Compliance - Chill blasters help meet strict safety standards by ensuring rapid temperature control post-blanching.

Cost and Practicality in Home and Commercial Kitchens

| Cooling Method | Cost | Practicality |

|---|---|---|

| Plastic Basin | Low initial investment, typically under $20, suitable for budget-conscious users. | Simple to use, requires manual water change to maintain cooling efficiency, ideal for small-scale home kitchens. |

| Chill Blaster | High upfront cost, often exceeding $2000, justified by rapid cooling and energy savings over time. | Automated cooling with precise temperature control, designed for high-volume commercial kitchens needing consistent blanching results. |

Related Important Terms

Rapid-chill technology

Rapid-chill technology in chill blasters significantly accelerates cooling of blanched items by using high-velocity cold air circulation, reducing cooling time compared to traditional plastic basins. This method minimizes microbial growth and preserves texture and nutritional quality better than the slower, passive cooling process of plastic basins.

Hydro-cooling efficiency

Chill blasters provide superior hydro-cooling efficiency compared to plastic basins by rapidly reducing the temperature of blanched items through continuous water circulation and high-velocity jets, minimizing thermal shock and preserving product quality. Plastic basins rely on static water, resulting in slower heat transfer and uneven cooling, which can compromise the texture and shelf life of the blanched produce.

Basin-to-blaster conversion

Converting from plastic basins to chill blasters for cooling blanched items enhances temperature consistency and reduces cooling time by up to 50%, improving product quality and lowering contamination risks. Chill blasters offer automated airflow control and uniform chilling, optimizing post-blanching processes compared to manual basin cooling methods.

Glycol immersion cooling

Glycol immersion cooling in chill blasters offers faster and more uniform temperature reduction compared to plastic basins, enhancing the preservation of blanched vegetables' texture and color. This method reduces thermal shock and microbial growth, ensuring higher product quality and extended shelf life.

Multi-stage blast cooling

Chill blasters provide efficient multi-stage blast cooling for blanched items, rapidly reducing temperature through controlled airflow and temperature modulation, which preserves texture and extends shelf life. Plastic basins lack precise temperature control and airflow, resulting in slower, uneven cooling that may compromise product quality and safety.

Microbial shock reduction

Plastic basins provide limited cooling efficiency for blanched items, often resulting in slower temperature drops that increase the risk of microbial growth. Chill blasters rapidly reduce item temperature through high-velocity chilled air, significantly minimizing microbial shock and enhancing food safety by preventing bacterial proliferation.

Ice matrix rapid cooling

Chill blasters use high-velocity cold air to rapidly reduce the temperature of blanched items, creating an ice matrix that efficiently locks in freshness and moisture. In contrast, plastic basins rely on slower water cooling, which results in less effective temperature reduction and a greater risk of texture degradation.

Ambient-to-core benchmarking

Plastic basins typically result in slower ambient-to-core temperature reduction due to limited heat transfer conductivity, leading to extended cooling times for blanched items. Chill blasters enhance cooling efficiency by rapidly lowering core temperatures through forced chilled air circulation, optimizing product safety and quality retention.

Thermal retention basins

Plastic basins exhibit higher thermal retention compared to chill blasters, causing slower cooling rates for blanched items and increasing the risk of microbial growth during the cooling phase. Chill blasters rapidly reduce surface temperature through forced air circulation, ensuring faster heat dissipation and better preservation of product quality after blanching.

Plastic basin vs Chill blaster for cooling blanched items. Infographic

cookingdiff.com

cookingdiff.com