Blanching and steam-blanching both effectively deactivate enzymes to preserve food quality, but steam-blanching offers a gentler method that reduces nutrient loss and prevents excessive water absorption. Steam-blanching uses hot steam to evenly heat food, minimizing leaching of water-soluble vitamins compared to traditional blanching in boiling water. Enzyme inactivation is typically faster and more uniform in steam-blanching, making it a preferred technique for maintaining color, texture, and flavor in fruits and vegetables.

Table of Comparison

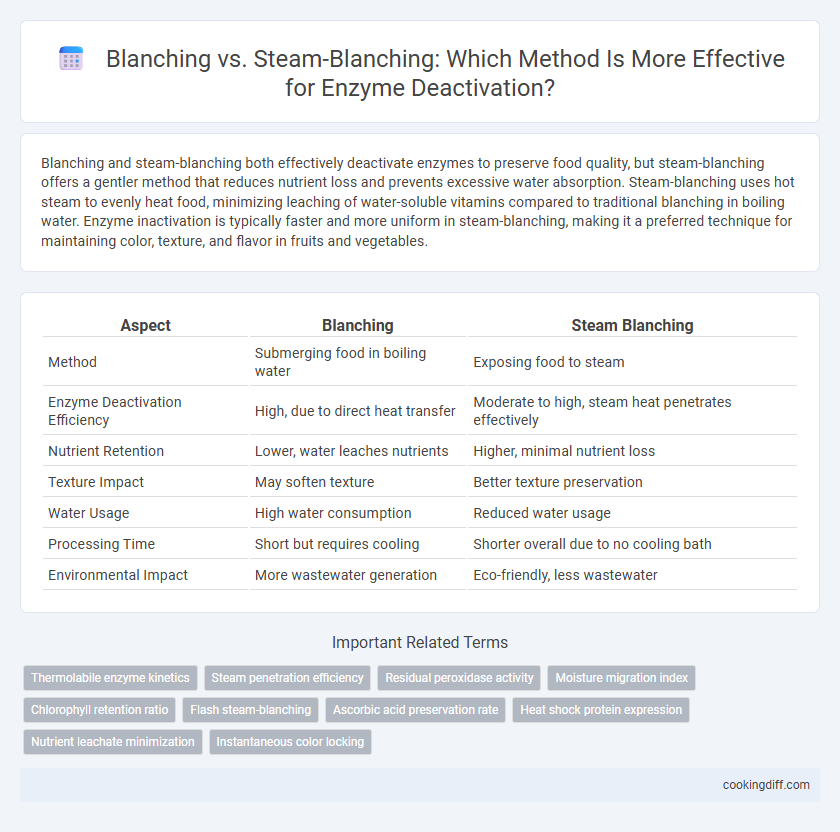

| Aspect | Blanching | Steam Blanching |

|---|---|---|

| Method | Submerging food in boiling water | Exposing food to steam |

| Enzyme Deactivation Efficiency | High, due to direct heat transfer | Moderate to high, steam heat penetrates effectively |

| Nutrient Retention | Lower, water leaches nutrients | Higher, minimal nutrient loss |

| Texture Impact | May soften texture | Better texture preservation |

| Water Usage | High water consumption | Reduced water usage |

| Processing Time | Short but requires cooling | Shorter overall due to no cooling bath |

| Environmental Impact | More wastewater generation | Eco-friendly, less wastewater |

Introduction to Enzyme Deactivation in Cooking

Enzyme deactivation is crucial in cooking to preserve the color, flavor, and texture of vegetables by halting enzymatic reactions that cause spoilage. Blanching, involving immersion in boiling water, and steam-blanching, using hot steam, are common methods for inactivating enzymes such as polyphenol oxidase and peroxidase. Steam-blanching often retains more nutrients and reduces leaching compared to traditional water blanching, making it a preferred technique in food processing.

What is Blanching?

Blanching is a thermal process that briefly exposes vegetables or fruits to boiling water or steam to inactivate enzymes responsible for spoilage. It preserves color, texture, and nutritional value by halting enzymatic activity before freezing or further processing.

- Water Blanching - Involves immersing produce in hot water, which efficiently transfers heat but can lead to nutrient leaching.

- Steam Blanching - Uses steam to inactivate enzymes with less nutrient loss and reduced water usage compared to water blanching.

- Enzyme Deactivation - Both methods target enzymes like polyphenol oxidase to prevent browning and degradation during storage.

The Science Behind Steam-Blanching

How does steam-blanching effectively deactivate enzymes compared to traditional blanching methods? Steam-blanching utilizes moist heat to rapidly penetrate food tissues, causing more efficient enzyme denaturation through consistent temperature exposure. This method reduces nutrient loss and preserves food texture better than conventional hot water blanching.

How Enzyme Activity Affects Food Quality

Blanching and steam-blanching effectively deactivate enzymes that cause food spoilage, but steam-blanching retains higher food quality by minimizing nutrient loss. Enzyme activity directly affects texture, color, and nutritional value, making precise control crucial for optimal food preservation.

- Blanching - Uses hot water immersion to deactivate enzymes but may lead to leaching of water-soluble nutrients.

- Steam-blanching - Employs steam to inactivate enzymes while better preserving vitamins and minerals.

- Enzyme deactivation - Essential for maintaining color, texture, and extending shelf life in processed foods.

Blanching: Process, Pros, and Cons

| Process | Blanching involves briefly boiling vegetables in water to deactivate enzymes that cause spoilage and preserve color, texture, and flavor. Water blanching heats food uniformly but requires immediate cooling to prevent overcooking. The process duration typically ranges from 1 to 5 minutes depending on the vegetable type. |

|---|---|

| Pros | Effective enzyme deactivation ensures extended shelf life and quality retention. Water blanching is cost-efficient and scalable for large production volumes. It facilitates easier peeling and improves texture for subsequent processing like freezing or drying. |

| Cons | Prolonged exposure to water and heat can leach water-soluble nutrients such as vitamin C and B vitamins. Excessive water absorption may degrade texture, resulting in softer produce. Wastewater management poses environmental concerns due to nutrient-rich discharge. |

Steam-Blanching: Process, Pros, and Cons

Steam-blanching involves exposing vegetables to steam to inactivate enzymes, preserving texture and nutrients more effectively than water blanching. This method reduces nutrient leaching and minimizes water use, enhancing overall product quality.

- Efficient enzyme deactivation - Steam-blanching rapidly inactivates enzymes by applying direct heat, preserving food freshness.

- Reduced nutrient loss - Unlike water blanching, steam-blanching limits water contact, retaining vitamins and minerals.

- High energy consumption - Steam generation requires considerable energy, potentially increasing processing costs.

Steam-blanching remains a preferred method for enzyme deactivation in industrial food processing due to its balance of quality preservation and efficiency.

Blanching vs Steam-Blanching: Effectiveness in Enzyme Deactivation

Blanching involves immersing vegetables in hot water to deactivate enzymes responsible for spoilage, effectively reducing enzymatic activity and preserving color and texture. Steam-blanching uses steam to achieve enzyme deactivation with less leaching of water-soluble nutrients, maintaining higher nutritional value.

Studies show steam-blanching offers superior retention of vitamins and minerals compared to hot water blanching, while maintaining comparable levels of enzyme inactivation. The choice between blanching and steam-blanching depends on processing goals, balancing enzyme deactivation efficiency and nutrient preservation.

Impact on Nutrient Retention and Color Preservation

Blanching and steam-blanching both target enzyme deactivation but differ in nutrient retention and color preservation. Steam-blanching better preserves water-soluble vitamins such as vitamin C and B-complex by minimizing nutrient leaching, while conventional blanching often causes higher nutrient loss due to direct water contact. Color preservation is enhanced in steam-blanching as it reduces pigment degradation and prevents excessive oxidation compared to traditional hot water blanching.

Practical Applications: When to Choose Blanching or Steam-Blanching

Blanching is preferred for vegetables that require rapid cooling and minimal texture alteration, enhancing shelf life and color retention. Steam-blanching offers superior enzyme deactivation for more delicate produce, preserving nutrients better due to reduced water contact.

Industries processing leafy greens and herbs often choose steam-blanching to prevent waterlogging and nutrient loss. For root vegetables and tubers, conventional blanching is favored for uniform heat transfer and ease of scalability in commercial operations.

Related Important Terms

Thermolabile enzyme kinetics

Blanching rapidly deactivates thermolabile enzymes such as peroxidase and polyphenol oxidase by exposing vegetables to boiling water, accelerating enzyme inactivation through efficient heat transfer. Steam-blanching offers more uniform heat application and reduced leaching of nutrients but may require precise control to achieve comparable kinetics for thermolabile enzyme deactivation without overprocessing.

Steam penetration efficiency

Steam-blanching offers superior steam penetration efficiency compared to conventional blanching, enabling faster and more uniform enzyme deactivation. This method reduces enzymatic browning and nutrient loss by delivering consistent heat transfer and minimizing water contact with food surfaces.

Residual peroxidase activity

Blanching achieves enzyme deactivation by exposing food to boiling water, but steam-blanching often results in lower residual peroxidase activity due to its gentler heat transfer and reduced leaching of water-soluble nutrients. Studies show steam-blanching maintains better product quality while ensuring more efficient peroxidase inactivation compared to traditional water blanching methods.

Moisture migration index

Blanching and steam-blanching differ significantly in their impact on the moisture migration index, with conventional blanching often causing higher moisture loss due to prolonged water exposure, while steam-blanching retains moisture more effectively by reducing direct water contact. This difference in moisture migration influences enzyme deactivation efficiency, as steam-blanching better preserves tissue integrity, ensuring more uniform and controlled enzyme inactivation.

Chlorophyll retention ratio

Steam-blanching preserves chlorophyll more effectively than conventional water blanching, resulting in a higher chlorophyll retention ratio due to reduced leaching and thermal degradation. This method enhances enzyme deactivation while maintaining vibrant green color and nutritional quality in vegetables.

Flash steam-blanching

Flash steam-blanching provides rapid enzyme deactivation by instantly exposing vegetables to high-temperature steam, minimizing nutrient loss compared to traditional water blanching. This method enhances texture preservation and reduces processing time, leading to improved product quality and shelf life.

Ascorbic acid preservation rate

Steam-blanching preserves ascorbic acid more effectively than traditional water blanching by minimizing leaching losses during the enzyme deactivation process. Studies indicate that steam-blanched vegetables retain up to 40% higher levels of ascorbic acid compared to those subjected to hot water blanching.

Heat shock protein expression

Blanching and steam-blanching differ significantly in their impact on heat shock protein (HSP) expression, with steam-blanching typically inducing higher levels of HSP production due to rapid and uniform heat transfer. This enhanced expression of heat shock proteins during steam-blanching contributes to more effective enzyme deactivation, improving the preservation of texture, color, and nutritional quality in treated foods.

Nutrient leachate minimization

Blanching using hot water immersion leads to higher nutrient leachate due to direct contact with water, whereas steam blanching effectively minimizes nutrient loss by reducing water exposure during enzyme deactivation. Steam blanching preserves water-soluble vitamins and antioxidants better, enhancing overall nutritional retention in vegetables.

Blanching vs Steam-blanching for enzyme deactivation. Infographic

cookingdiff.com

cookingdiff.com