Blanching involves briefly boiling vegetables to preserve color, texture, and nutrients, making it ideal for larger batches. Microblanching, a newer technique, uses precise, controlled heat exposure suited for small batch cooking, reducing nutrient loss and improving flavor retention. Small-scale chefs benefit from microblanching's efficiency and consistency compared to traditional blanching methods.

Table of Comparison

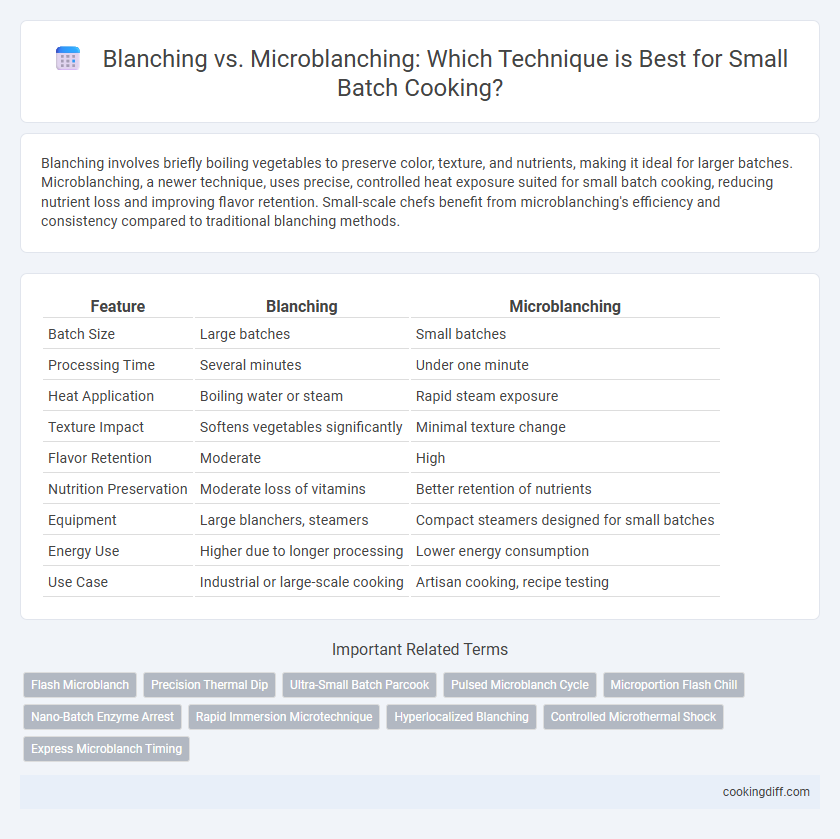

| Feature | Blanching | Microblanching |

|---|---|---|

| Batch Size | Large batches | Small batches |

| Processing Time | Several minutes | Under one minute |

| Heat Application | Boiling water or steam | Rapid steam exposure |

| Texture Impact | Softens vegetables significantly | Minimal texture change |

| Flavor Retention | Moderate | High |

| Nutrition Preservation | Moderate loss of vitamins | Better retention of nutrients |

| Equipment | Large blanchers, steamers | Compact steamers designed for small batches |

| Energy Use | Higher due to longer processing | Lower energy consumption |

| Use Case | Industrial or large-scale cooking | Artisan cooking, recipe testing |

Understanding Blanching: Basics and Benefits

| Blanching | Involves briefly boiling vegetables followed by rapid cooling to halt enzyme action, preserving color, texture, and nutritional value in small batch cooking. |

| Microblanching | A precise, shorter blanching method ideal for small quantities, minimizing nutrient loss while maintaining freshness and reducing cooking time. |

| Benefits | Both techniques enhance preservation, improve food safety by reducing microorganisms, and prepare ingredients for freezing or further cooking. |

What Is Microblanching? Definition and Key Differences

Microblanching is a precise blanching technique designed for small batch cooking, involving shorter blanching times and lower water volumes to preserve texture and nutrients. This method reduces enzymatic activity more efficiently than traditional blanching, making it ideal for delicate produce and maintaining color vibrancy.

Unlike conventional blanching, which often uses large volumes of boiling water or steam for longer periods, microblanching minimizes water use and heat exposure, enhancing flavor retention. Key differences include improved nutrient preservation, faster processing times, and suitability for high-value or limited-quantity food items in professional kitchens.

Efficiency in Small Batch Cooking: Blanching vs Microblanching

Blanching efficiently preserves color and texture by briefly boiling vegetables, making it ideal for small batch cooking with minimal equipment. Microblanching shortens processing time by using precise steam or water jets, enhancing nutrient retention in small portions.

In small batch cooking, blanching requires larger water volumes and longer cooling periods, reducing overall efficiency. Microblanching uses less water and energy, improving throughput and maintaining food quality. This method is particularly advantageous for chefs aiming to optimize time and resource use in limited quantities.

Time and Temperature: A Comparative Analysis

Blanching typically involves immersing vegetables in boiling water at 85-100degC for 1-5 minutes to halt enzymatic activity and preserve texture. Microblanching uses precise, shorter heat exposure, often at lower temperatures around 70-80degC for 30-90 seconds, allowing more delicate control in small batch cooking. This time and temperature difference directly impacts nutrient retention and flavor, making microblanching ideal for small-scale, high-quality culinary applications.

Nutrient Retention: Which Method Preserves More?

Microblanching preserves more nutrients than traditional blanching by reducing heat exposure time. This method minimizes the leaching of water-soluble vitamins, maintaining higher levels of vitamin C and B-complex vitamins in small batch cooking.

- Reduced Heat Exposure - Microblanching cooks vegetables faster, limiting nutrient degradation caused by prolonged heat.

- Less Nutrient Leaching - The shorter blanching time in microblanching helps retain water-soluble vitamins better than traditional blanching.

- Improved Vitamin Retention - Studies show microblanched vegetables have significantly higher vitamin C and folate levels post-cooking.

Texture and Flavor: Impact of Each Technique

Blanching rapidly cooks vegetables by briefly immersing them in boiling water, which helps preserve texture and brightens color while slightly softening the produce. Microblanching, a technique using precise, shorter exposure times and controlled temperatures, enhances texture retention by maintaining a firmer bite and intensifies natural flavors through reduced nutrient leaching. Both methods improve shelf life, but microblanching is preferred for small batch cooking where optimal texture and flavor are critical.

Equipment Needed for Blanching and Microblanching

Traditional blanching requires larger equipment such as boiling pots or steamers suitable for batch processing, while microblanching uses compact, precise devices tailored for small-scale culinary applications. The equipment for microblanching often integrates temperature controls and timers for consistent results in small batches.

- Large boiling pots - Essential for traditional blanching to submerge vegetables fully in boiling water.

- Steamers with baskets - Used for steam blanching, allowing quick heat exposure without water contact.

- Microblanching units - Designed compact machines providing controlled heat and timing, ideal for small batch cooking.

Best Ingredients for Each Method in Small Batches

Blanching is ideal for robust vegetables like green beans, broccoli, and carrots, as it quickly softens their texture and preserves vibrant color in small batch cooking. Microblanching suits tender ingredients such as leafy greens and delicate herbs, allowing precise control over texture and flavor retention.

For small batches, blanching ingredients should be firm and able to withstand brief boiling without losing integrity, ensuring crispness and nutrient retention. Microblanching benefits particularly fresh, easily overcooked ingredients where minimal heat exposure enhances freshness without damaging cell structure.

Practical Applications: When to Choose Blanching or Microblanching

When should you choose blanching over microblanching for small batch cooking? Blanching is ideal for preserving the color, texture, and nutritional value of vegetables in larger quantities or when preparing for freezing. Microblanching works best for very small batches, offering quicker heat exposure and minimal nutrient loss, perfect for delicate ingredients or immediate use.

Related Important Terms

Flash Microblanch

Flash Microblanch offers a precise, rapid heat treatment method ideal for small batch cooking, preserving nutrient retention and enhancing texture compared to traditional blanching. This technique uses controlled, high-heat, short-duration exposure to inactivate enzymes effectively while minimizing moisture loss and color degradation.

Precision Thermal Dip

Precision Thermal Dip offers enhanced control over temperature and timing compared to traditional blanching methods, making it ideal for small batch cooking where consistency is critical. Microblanching uses precise thermal regulation to minimize nutrient loss and improve texture retention, optimizing the quality of individual servings.

Ultra-Small Batch Parcook

Blanching involves briefly boiling vegetables before cooling them rapidly to preserve color and texture, ideal for medium to large batches, while microblanching targets ultra-small batch parcooking, offering precise heat application and minimal nutrient loss for small-scale culinary operations. Ultra-small batch microblanching optimizes cooking consistency and extends shelf life, making it essential for specialty kitchens and artisanal food production.

Pulsed Microblanch Cycle

Pulsed microblanch cycles offer precise temperature and time control in small batch cooking, reducing nutrient loss and preserving texture compared to traditional blanching methods. This technique uses short, intermittent heating pulses to achieve uniform heat distribution, enhancing flavor retention and minimizing overcooking in delicate ingredients.

Microportion Flash Chill

Microblanching offers precise temperature control and faster cooling through Microportion Flash Chill, preserving nutrient retention and texture in small batch cooking better than traditional blanching. This method reduces enzymatic activity swiftly while minimizing moisture loss, optimizing food quality for artisanal and small-scale operations.

Nano-Batch Enzyme Arrest

Blanching rapidly inactivates enzymes in vegetables to preserve color, texture, and nutrients, while microblanching offers precise temperature control for nano-batch enzyme arrest, minimizing nutrient loss and cooking time. Nano-batch enzyme arrest in microblanching ensures targeted heat exposure, enhancing efficiency and product quality in small-scale food processing.

Rapid Immersion Microtechnique

Rapid Immersion Microtechnique, a key method in microblanching, offers precise temperature control and reduced cooking time compared to traditional blanching, preserving texture and nutrient content more effectively in small batch cooking. This technique uses quick, direct contact with hot water or steam, minimizing nutrient loss and enhancing color retention in vegetables during rapid processing.

Hyperlocalized Blanching

Hyperlocalized blanching targets specific food areas using precise heat application, preserving texture and nutrients better than traditional blanching techniques suited for small batch cooking. Microblanching enhances efficiency by reducing processing time and energy consumption, making it ideal for artisanal kitchens focusing on quality and sustainability.

Controlled Microthermal Shock

Blanching involves briefly boiling vegetables to inactivate enzymes and preserve quality, but microblanching applies controlled microthermal shock, delivering precise heat exposure to smaller portions for enhanced texture and nutrient retention in small batch cooking. Controlled microthermal shock minimizes overcooking and moisture loss, making microblanching ideal for artisanal food preparation where consistency and flavor are paramount.

Blanching vs Microblanching for small batch cooking. Infographic

cookingdiff.com

cookingdiff.com