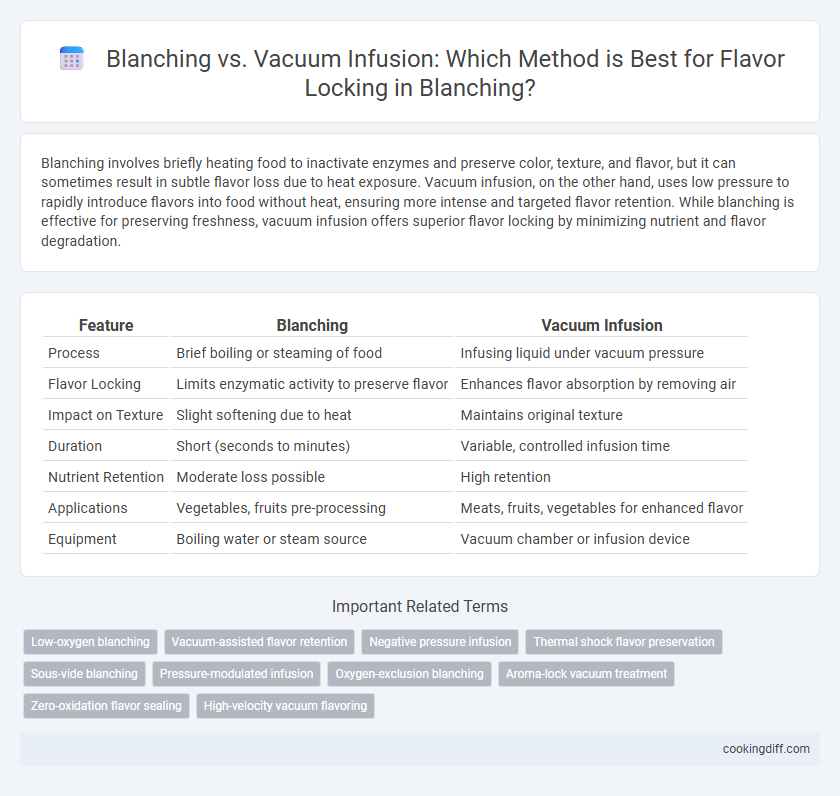

Blanching involves briefly heating food to inactivate enzymes and preserve color, texture, and flavor, but it can sometimes result in subtle flavor loss due to heat exposure. Vacuum infusion, on the other hand, uses low pressure to rapidly introduce flavors into food without heat, ensuring more intense and targeted flavor retention. While blanching is effective for preserving freshness, vacuum infusion offers superior flavor locking by minimizing nutrient and flavor degradation.

Table of Comparison

| Feature | Blanching | Vacuum Infusion |

|---|---|---|

| Process | Brief boiling or steaming of food | Infusing liquid under vacuum pressure |

| Flavor Locking | Limits enzymatic activity to preserve flavor | Enhances flavor absorption by removing air |

| Impact on Texture | Slight softening due to heat | Maintains original texture |

| Duration | Short (seconds to minutes) | Variable, controlled infusion time |

| Nutrient Retention | Moderate loss possible | High retention |

| Applications | Vegetables, fruits pre-processing | Meats, fruits, vegetables for enhanced flavor |

| Equipment | Boiling water or steam source | Vacuum chamber or infusion device |

Understanding Blanching: Basics and Purpose

Blanching is a heat treatment process that inactivates enzymes to preserve color, texture, and nutritional value in foods. It serves as a critical step before freezing or further processing, ensuring flavor retention by halting spoilage reactions.

- Enzyme Inactivation - Blanching uses hot water or steam to stop enzymatic activity that causes food degradation.

- Flavor Preservation - By halting enzymatic processes, blanching helps maintain the natural flavor of fruits and vegetables.

- Preparation Step - Often performed before vacuum infusion, blanching ensures better absorption and locking of flavors during subsequent treatments.

What is Vacuum Infusion in Cooking?

Vacuum infusion in cooking is a process that utilizes negative pressure to rapidly infuse flavors, liquids, or marinades into food. This technique enhances flavor penetration by expanding the food's cellular structure, allowing for quicker and more intense absorption compared to traditional methods.

Unlike blanching, which involves brief boiling to deactivate enzymes and preserve color and texture, vacuum infusion specifically targets flavor locking without cooking the food. This method is ideal for delicate ingredients, maintaining their freshness while delivering robust taste profiles.

Key Differences: Blanching vs Vacuum Infusion

What are the key differences between blanching and vacuum infusion for flavor locking? Blanching uses brief heat treatment to inactivate enzymes and preserve color but can cause some nutrient loss. Vacuum infusion injects flavors directly under reduced pressure, enhancing taste without heat damage and maintaining nutritional quality.

Flavor Retention: How Effective is Blanching?

| Blanching | Vacuum Infusion |

|---|---|

| Blanching involves briefly boiling vegetables to inactivate enzymes, significantly slowing down enzymatic degradation and preserving natural flavors. | Vacuum infusion enhances flavor retention by introducing flavors directly into the food matrix, offering precise control over flavor intensity. |

| While blanching reduces nutrient and flavor loss compared to other heat treatments, some volatile aroma compounds may still be diminished due to heat exposure. | Vacuum infusion maintains a higher level of volatile compounds, resulting in more robust and longer-lasting flavor profiles. |

| Blanching is cost-effective and widely adopted for flavor retention but may not match the efficacy of vacuum infusion in flavor enhancement and locking. | Vacuum infusion is a specialized technique that maximizes flavor retention by minimizing oxidation and leaching, outperforming blanching in overall flavor preservation. |

Vacuum Infusion: Superior Flavor Locking Technique?

Vacuum infusion offers a superior method for flavor locking compared to traditional blanching by effectively enhancing the penetration of flavors into food matrices. This technique uses reduced pressure to remove air and allow rapid, deep infusion of seasonings without the heat damage associated with blanching.

- Enhanced Flavor Absorption - Vacuum infusion significantly improves the uniformity and depth of flavor penetration in fruits and vegetables.

- Preservation of Nutrients - Unlike blanching, vacuum infusion avoids heat exposure, preserving sensitive vitamins and antioxidants.

- Extended Shelf Life - By locking flavors and reducing microbial activity, vacuum infusion helps maintain product quality for longer periods.

The technology presents a promising alternative for the food industry seeking advanced preservation and flavor enhancement methods.

Texture and Color: Comparing Outcomes

Blanching effectively stabilizes vibrant color and maintains a crisp texture by inactivating enzymes that cause degradation, resulting in a fresh appearance. Vacuum infusion preserves more natural flavor compounds and enhances color retention by minimizing oxidation, while also improving texture through controlled infusion of liquids. Comparing outcomes, blanching offers more uniform texture firmness, whereas vacuum infusion allows for higher flavor intensity without compromising the visual appeal of fruits and vegetables.

Nutrient Preservation in Blanching and Vacuum Infusion

Blanching effectively preserves nutrients like vitamin C and carotenoids by rapidly heating vegetables to inactivate enzymes that cause spoilage. However, some water-soluble vitamins may leach out during the brief boiling process.

Vacuum infusion enhances nutrient retention by infusing flavors and nutrients under reduced pressure, minimizing nutrient loss compared to traditional methods. This technique allows better penetration of antioxidants and vitamins into the food matrix, improving overall nutrient density. Both methods offer distinct advantages, but vacuum infusion generally provides superior nutrient preservation alongside flavor enhancement.

Applications in Culinary Practices

Blanching involves briefly boiling vegetables to deactivate enzymes, preserving color and texture while locking in some flavors, commonly used in preparing greens and root vegetables. Vacuum infusion, by contrast, forces marinade or flavoring agents deep into the food matrix under reduced pressure, enhancing flavor penetration beyond surface levels.

In culinary practices, blanching is ideal for softening ingredients before freezing or further cooking, maintaining nutritional quality and visual appeal. Vacuum infusion excels in gourmet applications where intense, evenly distributed flavors are desired, such as in marinating meats or fruit for complex dishes.

Equipment and Techniques: What You Need

Blanching requires simple equipment such as a pot of boiling water or steam basket, making it accessible for quick flavor locking by halting enzyme activity. Vacuum infusion demands specialized vacuum chambers and pumps to efficiently force flavors into porous foods under reduced pressure.

- Blanching Equipment - Utilizes basic kitchen tools like boiling water pots or steamers to inactivate enzymes and preserve color and flavor.

- Vacuum Infusion Equipment - Requires vacuum pumps and airtight chambers to create a pressure differential for effective flavor penetration.

- Technique Differences - Blanching is a thermal process focusing on enzyme deactivation, while vacuum infusion is a mechanical technique enhancing flavor absorption without heat.

Related Important Terms

Low-oxygen blanching

Low-oxygen blanching reduces enzymatic activity and oxidation, preserving natural flavors more effectively than traditional blanching methods. Compared to vacuum infusion, this technique limits oxygen exposure during heat treatment, enhancing flavor retention and nutrient stability in fruits and vegetables.

Vacuum-assisted flavor retention

Vacuum infusion significantly enhances flavor retention by creating low-pressure environments that drive deeper and faster penetration of marinades and seasonings compared to blanching, which mainly relies on heat to inactivate enzymes but often results in flavor loss due to leaching. This vacuum-assisted technique preserves volatile compounds and natural textures more effectively, ensuring intensified taste profiles and improved food quality.

Negative pressure infusion

Blanching denatures enzymes to preserve color and texture but often results in nutrient loss and diminished flavor intensity. Negative pressure infusion enhances flavor locking by using vacuum to rapidly infuse seasonings into food, maintaining taste without thermal degradation.

Thermal shock flavor preservation

Blanching uses thermal shock to rapidly halt enzymatic activity, effectively preserving the natural flavors and colors of vegetables by preventing oxidation and flavor loss. Vacuum infusion enhances flavor locking by creating pressure differentials that infuse flavors deeper into the food matrix, but it does not provide the immediate enzymatic inactivation achieved through blanching's thermal shock process.

Sous-vide blanching

Sous-vide blanching preserves essential nutrients and intensifies natural flavors by maintaining precise temperature control, unlike traditional blanching which can cause nutrient loss and flavor dilution. Vacuum infusion enhances flavor absorption but may disrupt texture, whereas sous-vide blanching locks in flavors while retaining the food's integrity and moisture.

Pressure-modulated infusion

Pressure-modulated infusion during vacuum infusion enhances flavor locking by enabling better penetration of marinades into food tissues compared to traditional blanching, which primarily focuses on enzyme inactivation and surface treatment. Unlike blanching, this technique utilizes controlled pressure variations to optimize infusion depth and uniformity, preserving both flavor intensity and texture.

Oxygen-exclusion blanching

Oxygen-exclusion blanching effectively preserves flavor by minimizing oxidative degradation, unlike vacuum infusion which incorporates flavors but may not fully prevent oxidation. This method uses steam or hot water in low-oxygen environments to inactivate enzymes while locking in natural taste compounds.

Aroma-lock vacuum treatment

Vacuum infusion, particularly Aroma-lock vacuum treatment, surpasses blanching by preserving volatile aromatic compounds through low-pressure conditions that minimize thermal degradation and oxidation. This method enhances flavor retention and intensifies aroma profiles more effectively than traditional blanching, which often leads to significant loss of essential oils and sensory quality.

Zero-oxidation flavor sealing

Blanching effectively inactivates enzymes to prevent oxidation but often leads to nutrient loss and reduced flavor intensity, whereas vacuum infusion achieves zero-oxidation flavor sealing by infusing flavors directly into produce under reduced pressure without heat-induced degradation. Vacuum infusion maintains the original taste and nutritional profile, providing superior flavor retention compared to traditional blanching methods.

Blanching vs Vacuum infusion for flavor locking. Infographic

cookingdiff.com

cookingdiff.com