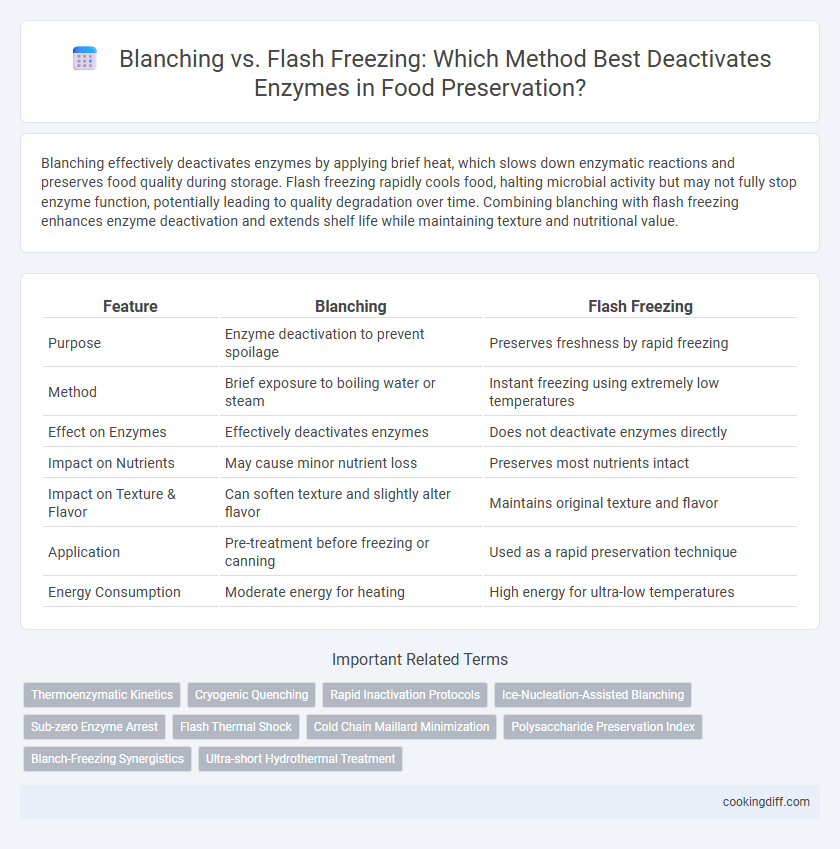

Blanching effectively deactivates enzymes by applying brief heat, which slows down enzymatic reactions and preserves food quality during storage. Flash freezing rapidly cools food, halting microbial activity but may not fully stop enzyme function, potentially leading to quality degradation over time. Combining blanching with flash freezing enhances enzyme deactivation and extends shelf life while maintaining texture and nutritional value.

Table of Comparison

| Feature | Blanching | Flash Freezing |

|---|---|---|

| Purpose | Enzyme deactivation to prevent spoilage | Preserves freshness by rapid freezing |

| Method | Brief exposure to boiling water or steam | Instant freezing using extremely low temperatures |

| Effect on Enzymes | Effectively deactivates enzymes | Does not deactivate enzymes directly |

| Impact on Nutrients | May cause minor nutrient loss | Preserves most nutrients intact |

| Impact on Texture & Flavor | Can soften texture and slightly alter flavor | Maintains original texture and flavor |

| Application | Pre-treatment before freezing or canning | Used as a rapid preservation technique |

| Energy Consumption | Moderate energy for heating | High energy for ultra-low temperatures |

Understanding Enzyme Deactivation in Food Preservation

Blanching effectively deactivates enzymes by applying brief heat treatment, which halts enzymatic reactions that cause spoilage in fruits and vegetables. Flash freezing lowers temperatures rapidly but does not fully deactivate enzymes, slowing their activity instead.

- Blanching - uses hot water or steam to denature enzymes, preserving texture, color, and flavor.

- Flash Freezing - rapidly freezes food to slow enzyme activity but requires blanching for complete deactivation.

- Enzyme Deactivation - critical for preventing oxidative browning and nutrient degradation in preserved foods.

Effective enzyme deactivation through blanching is essential for long-term quality in frozen and canned foods.

What Is Blanching? Process and Benefits

Blanching is a food processing technique involving brief exposure to boiling water or steam to inactivate enzymes that cause spoilage. This method preserves color, texture, and nutritional value while preparing vegetables for freezing or further processing.

- Enzyme Deactivation - Blanching effectively stops enzymatic reactions that lead to discoloration and nutrient loss in vegetables.

- Process Duration - Typically lasts from 30 seconds to a few minutes depending on the vegetable type and thickness.

- Quality Preservation - Maintains sensory attributes and extends shelf life by preventing microbial growth during storage.

Flash Freezing Explained: A Quick Overview

Flash freezing rapidly lowers the temperature of food to below -40degF (-40degC) within minutes, halting enzyme activity and preserving texture and nutrients better than traditional blanching. This ultra-fast freezing process minimizes ice crystal formation, reducing cellular damage in fruits and vegetables.

Unlike blanching, which uses heat to deactivate enzymes and can cause nutrient loss, flash freezing maintains high antioxidant levels and natural flavors. The method is ideal for preserving enzyme-sensitive foods while extending shelf life with minimal quality compromise.

Comparing Blanching and Flash Freezing Techniques

Blanching uses hot water or steam to deactivate enzymes by heat, preserving food color and texture but may cause nutrient loss. Flash freezing rapidly lowers the temperature to halt enzyme activity, maintaining more nutrients and texture but without cooking effects.

- Blanching involves heat treatment - It deactivates enzymes through thermal inactivation, preventing enzymatic spoilage.

- Flash freezing employs rapid cooling - It inhibits enzyme activity by quickly reaching subzero temperatures.

- Blanching may reduce nutrient content - Heat exposure can leach water-soluble vitamins like vitamin C and B-complex.

Impact on Nutrient Retention: Blanching vs Flash Freezing

Blanching rapidly heats vegetables to deactivate enzymes, which can cause a moderate loss of heat-sensitive nutrients such as vitamin C and B vitamins. Flash freezing, on the other hand, instantly lowers the temperature, better preserving these nutrients by minimizing enzymatic activity without prolonged heat exposure.

While blanching is effective in preventing spoilage, it often results in greater nutrient degradation compared to flash freezing. Flash freezing maintains higher levels of antioxidants and phytonutrients, ensuring superior nutrient retention in frozen produce.

Texture and Color Changes in Both Methods

How do blanching and flash freezing affect texture and color in enzyme deactivation? Blanching involves brief exposure to hot water or steam, causing partial softening and slight color change due to heat-induced enzymatic inactivation. Flash freezing preserves texture and color more effectively by rapidly lowering temperature, minimizing enzymatic activity without heat damage.

Effectiveness in Enzyme Deactivation

Blanching is highly effective in enzyme deactivation by applying heat to fruits and vegetables, rapidly inactivating enzymes like polyphenol oxidase and peroxidase. Flash freezing slows enzyme activity but does not completely deactivate enzymes, allowing residual enzymatic reactions to occur during storage. Consequently, blanching ensures longer shelf life and better preservation of color, flavor, and texture compared to flash freezing alone.

Suitability for Different Types of Produce

Blanching is highly effective for enzyme deactivation in firm vegetables like green beans and broccoli, as the brief heat treatment preserves texture while inactivating enzymes. Flash freezing suits delicate produce such as berries and leafy greens, minimizing structural damage due to rapid temperature changes.

Blanching's suitability for root vegetables and robust produce stems from its ability to uniformly heat and halt enzymatic activity, enhancing shelf life. Flash freezing is preferable for soft fruits and salad greens where maintaining cell integrity and preventing enzymatic browning are critical. Choosing the method depends on produce texture, enzyme sensitivity, and desired post-processing quality.

Energy and Time Efficiency: Method Comparison

| Method | Energy Efficiency | Time Efficiency | Enzyme Deactivation |

|---|---|---|---|

| Blanching | High energy consumption due to prolonged heating | Moderate time requirement, typically 1-5 minutes | Effective inactivating polyphenol oxidase and peroxidase enzymes |

| Flash Freezing | Lower energy demands, rapid temperature reduction | Very fast process, often within seconds | Partial enzyme inactivation, less effective than blanching |

Related Important Terms

Thermoenzymatic Kinetics

Blanching rapidly deactivates enzymes through thermal denaturation by exposing vegetables to hot water or steam typically between 70-100degC for short durations, effectively reducing enzyme activity such as peroxidase and polyphenol oxidase. Flash freezing, although preserving nutritional quality better, relies on low temperatures that slow down but do not immediately inactivate enzymes, resulting in continued thermoenzymatic kinetics at subzero temperatures unless combined with blanching for complete enzyme deactivation.

Cryogenic Quenching

Blanching effectively deactivates enzymes by applying rapid heat, but cryogenic quenching during flash freezing halts enzymatic activity almost instantaneously by exposing food to ultra-low temperatures, preserving nutrients and texture more efficiently. Cryogenic quenching minimizes thermal degradation, making it superior to blanching for maintaining quality in enzyme-sensitive foods during preservation.

Rapid Inactivation Protocols

Blanching effectively deactivates enzymes through rapid heat application, preventing enzymatic browning and texture degradation in vegetables. Flash freezing also inhibits enzyme activity by quickly lowering temperature, but blanching remains preferred for immediate enzyme inactivation in commercial food processing due to its consistency and speed.

Ice-Nucleation-Assisted Blanching

Ice-nucleation-assisted blanching enhances enzyme deactivation by precisely controlling ice crystal formation, minimizing thermal damage compared to traditional blanching methods. This technique improves preservation of texture and nutritional quality while effectively inhibiting enzymatic activity prior to flash freezing.

Sub-zero Enzyme Arrest

Blanching effectively deactivates enzymes by applying controlled heat, which halts enzymatic activity to preserve food quality, whereas flash freezing primarily slows enzyme reactions without fully arresting them. Sub-zero enzyme arrest achieved through rapid freezing maintains nutritional and sensory attributes but may require prior blanching to ensure complete enzyme deactivation.

Flash Thermal Shock

Flash thermal shock during flash freezing rapidly deactivates enzymes by applying extreme cold, preserving food texture and nutrients better than traditional blanching. Unlike blanching, which uses hot water or steam and can cause nutrient loss, flash freezing's instant temperature drop minimizes enzymatic activity without compromising food quality.

Cold Chain Maillard Minimization

Blanching effectively deactivates enzymes by applying short bursts of heat, reducing enzymatic browning and preserving color, but may initiate Maillard reactions if overheated. Flash freezing, combined with a strict cold chain, minimizes Maillard reactions by rapidly lowering temperature and limiting enzyme activity without thermal stress, maintaining product quality and nutritional value.

Polysaccharide Preservation Index

Blanching effectively deactivates enzymes but can reduce the Polysaccharide Preservation Index (PPI) due to heat-induced degradation, whereas flash freezing maintains a higher PPI by rapidly lowering temperature and minimizing enzymatic activity without thermal damage. Studies indicate flash freezing preserves up to 85% of polysaccharides compared to blanching, which often retains only about 60%.

Blanch-Freezing Synergistics

Blanching effectively deactivates enzymes by quickly heating vegetables to halt enzymatic activity, preserving color and texture before freezing. Combining blanching with flash freezing leverages the synergistic effects of enzyme deactivation and rapid temperature reduction, which maintains nutrient quality and extends shelf life in frozen produce.

Blanching vs Flash Freezing for enzyme deactivation Infographic

cookingdiff.com

cookingdiff.com