Blanching involves briefly boiling vegetables to inactivate enzymes and preserve color, but it can cause some loss of vibrancy due to high heat exposure. Cryo-blanching uses extremely low temperatures, often with liquid nitrogen or dry ice, to quickly cool the vegetables and better retain their bright, natural color. This method minimizes color degradation and maintains a fresher appearance compared to traditional blanching.

Table of Comparison

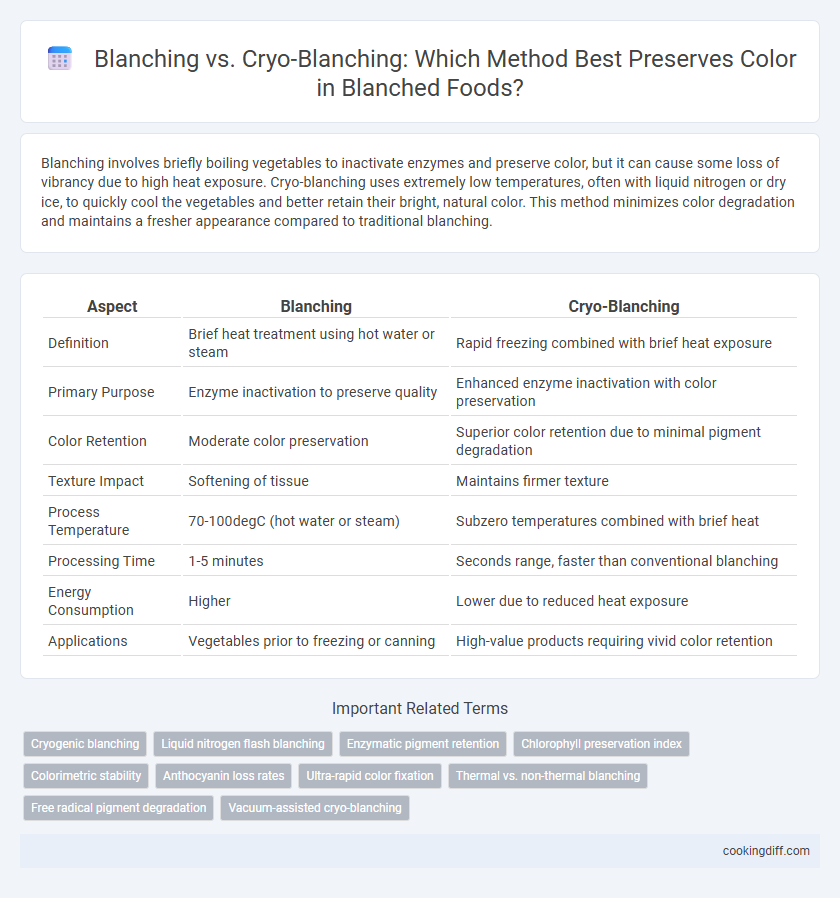

| Aspect | Blanching | Cryo-Blanching |

|---|---|---|

| Definition | Brief heat treatment using hot water or steam | Rapid freezing combined with brief heat exposure |

| Primary Purpose | Enzyme inactivation to preserve quality | Enhanced enzyme inactivation with color preservation |

| Color Retention | Moderate color preservation | Superior color retention due to minimal pigment degradation |

| Texture Impact | Softening of tissue | Maintains firmer texture |

| Process Temperature | 70-100degC (hot water or steam) | Subzero temperatures combined with brief heat |

| Processing Time | 1-5 minutes | Seconds range, faster than conventional blanching |

| Energy Consumption | Higher | Lower due to reduced heat exposure |

| Applications | Vegetables prior to freezing or canning | High-value products requiring vivid color retention |

Introduction to Blanching and Cryo-Blanching

Blanching is a heat treatment process used to inactivate enzymes in vegetables, preserving color and texture before freezing or further processing. Cryo-blanching employs ultra-low temperatures, such as liquid nitrogen, to achieve enzymatic inactivation while minimizing color loss and nutrient degradation.

- Blanching - Uses hot water or steam to quickly heat vegetables and halt enzymatic activity.

- Cryo-blanching - Utilizes rapid freezing with cryogenic liquids to preserve color more effectively than traditional methods.

- Color Preservation - Cryo-blanching generally maintains brighter, more natural colors by reducing thermal damage and pigment degradation.

The Science Behind Color Preservation

| Blanching uses hot water or steam to inactivate enzymes like polyphenol oxidase and peroxidase, which cause color deterioration in vegetables. Cryo-blanching involves rapidly freezing produce to slow enzymatic reactions without heat damage, preserving chlorophyll and carotenoid pigments more effectively. Studies show cryo-blanching better maintains vibrant green and bright red colors by minimizing pigment degradation and enzymatic browning. |

Traditional Blanching: Methods and Effects

How does traditional blanching compare to cryo-blanching in preserving color? Traditional blanching methods, such as hot water or steam blanching, effectively inactivate enzymes but often cause some color degradation due to heat exposure. Cryo-blanching, which uses freezing temperatures, better retains the vibrant color of vegetables by minimizing thermal damage.

Cryo-Blanching: A Modern Alternative

Cryo-blanching utilizes liquid nitrogen or carbon dioxide to rapidly cool vegetables, effectively preserving their vibrant color better than traditional thermal blanching. This modern technique minimizes enzymatic activity and color degradation by preventing prolonged exposure to heat, making it ideal for high-quality food processing. Studies show that cryo-blanched produce retains higher levels of chlorophyll and anthocyanins, enhancing overall visual appeal and nutritional value.

Comparing Color Retention: Blanching vs Cryo-Blanching

Blanching involves brief exposure to hot water or steam to inactivate enzymes, which can cause some loss of vibrant color in vegetables. Cryo-blanching, using ultra-low temperatures such as liquid nitrogen, effectively preserves chlorophyll and anthocyanins, resulting in superior color retention.

Studies demonstrate that cryo-blanched produce maintains higher levels of green and red pigments compared to conventional blanching. This enhanced color preservation improves both visual appeal and perceived freshness in fruits and vegetables.

Impact on Nutrient Loss and Texture

Blanching can cause significant nutrient loss, particularly of water-soluble vitamins like vitamin C and B-complex due to heat exposure. Cryo-blanching, using liquid nitrogen or super-cooled air, better preserves these nutrients by minimizing thermal degradation. Texture retention is superior in cryo-blanched produce, maintaining firmness and cellular integrity compared to conventional hot-water or steam blanching methods.

Practical Applications in Home and Industry

Blanching is widely used in both home kitchens and food industries to preserve the vibrant color of vegetables before freezing or cooking. Cryo-blanching, utilizing liquid nitrogen or very low temperatures, offers superior color retention by minimizing enzyme activity and cellular damage compared to traditional hot water or steam blanching.

- Home Cooking - Traditional blanching with boiling water is accessible and effective for preserving color in small batches of vegetables.

- Food Industry - Cryo-blanching is preferred for large-scale processing due to enhanced color preservation and reduced nutrient loss.

- Cost and Equipment - Cryo-blanching requires specialized equipment and higher energy input, limiting its practicality for home use.

Choosing the appropriate blanching method depends on balancing color quality, cost, and available technology for the intended application.

Equipment and Requirements for Each Method

Blanching typically requires hot water baths or steamers to quickly inactivate enzymes, while cryo-blanching uses liquid nitrogen or dry ice for rapid cooling and preservation of vibrant color. Each method demands specific equipment to optimize the process and maintain the quality of the produce.

- Blanching Equipment - Hot water tanks or steamers are essential to raise the temperature rapidly and uniformly during traditional blanching.

- Cryo-blanching Equipment - Liquid nitrogen chambers or dry ice containers enable instant freezing, minimizing color degradation.

- Operational Requirements - Blanching requires temperature control and timing to prevent overcooking, while cryo-blanching requires safe handling of cryogenic materials and precise temperature monitoring.

Pros and Cons: Blanching vs Cryo-Blanching

Blanching uses hot water or steam to inactivate enzymes, effectively preserving color but can cause slight nutrient loss and texture softening. Cryo-blanching, involving rapid freezing techniques, better maintains vibrant color and texture with minimal nutrient degradation.

Blanching is cost-effective and widely used in the food industry but may lead to color fading and reduced shelf life. Cryo-blanching offers superior color retention and extends fresh appearance, yet requires higher energy input and more specialized equipment. Both methods are valuable depending on product type, desired quality, and processing capabilities.

Related Important Terms

Cryogenic blanching

Cryogenic blanching, using liquid nitrogen or carbon dioxide, preserves the vibrant green color of vegetables more effectively than traditional hot water blanching by rapidly arresting enzymatic activity and minimizing pigment degradation. This method enhances color retention and extends shelf life while maintaining nutritional quality and texture, making it superior for high-quality frozen products.

Liquid nitrogen flash blanching

Liquid nitrogen flash blanching dramatically enhances color preservation in vegetables by rapidly halting enzymatic reactions responsible for browning, outperforming traditional hot water blanching methods. This cryo-blanching technique maintains vibrant pigments such as chlorophyll and carotenoids, resulting in superior visual appeal and nutrient retention.

Enzymatic pigment retention

Blanching inactivates enzymes like polyphenol oxidase but can cause pigment loss due to heat exposure, whereas cryo-blanching employs ultra-low temperatures to better preserve enzymatic pigments by minimizing thermal degradation. Studies show cryo-blanching results in higher retention of chlorophyll and anthocyanins, maintaining vibrant color and enhancing the visual quality of fresh produce.

Chlorophyll preservation index

Cryo-blanching significantly enhances the Chlorophyll Preservation Index compared to traditional blanching methods, maintaining vibrant green coloration in vegetables. This technique reduces pigment degradation by rapid cooling, resulting in superior retention of chlorophyll and improved visual quality during storage.

Colorimetric stability

Cryo-blanching enhances colorimetric stability by significantly reducing enzymatic browning and pigment degradation compared to conventional blanching, preserving the vibrant hues of fruits and vegetables. This method minimizes chlorophyll and carotenoid loss, resulting in superior color retention and prolonged freshness during storage.

Anthocyanin loss rates

Blanching causes significant anthocyanin degradation due to thermal exposure, with loss rates often exceeding 40%, whereas cryo-blanching preserves anthocyanin content more effectively, maintaining losses below 20%. This enhanced retention in cryo-blanching is attributed to rapid temperature reduction that limits pigment degradation and enzymatic activity.

Ultra-rapid color fixation

Cryo-blanching enables ultra-rapid color fixation by rapidly lowering the temperature, which minimizes pigment degradation and preserves the vibrant natural color of vegetables more effectively than traditional blanching. This method reduces enzymatic activity without the thermal damage associated with hot water or steam blanching, maintaining higher levels of chlorophyll and carotenoids.

Thermal vs. non-thermal blanching

Thermal blanching uses hot water or steam to inactivate enzymes but often causes color degradation due to high temperatures, while non-thermal cryo-blanching employs liquid nitrogen or refrigerated air to preserve color vibrancy by minimizing heat exposure. Cryo-blanching maintains chlorophyll stability more effectively than traditional thermal methods, resulting in brighter, fresher-looking vegetables.

Free radical pigment degradation

Blanching reduces free radical pigment degradation by quickly deactivating oxidative enzymes but can cause color loss due to heat exposure; cryo-blanching minimizes pigment degradation more effectively by using low temperatures to preserve chlorophyll and anthocyanins with reduced free radical activity. Studies show cryo-blanching maintains vibrant color and antioxidant properties better than traditional hot water blanching by limiting free radical-induced pigment breakdown.

Blanching vs Cryo-blanching for preserving color. Infographic

cookingdiff.com

cookingdiff.com