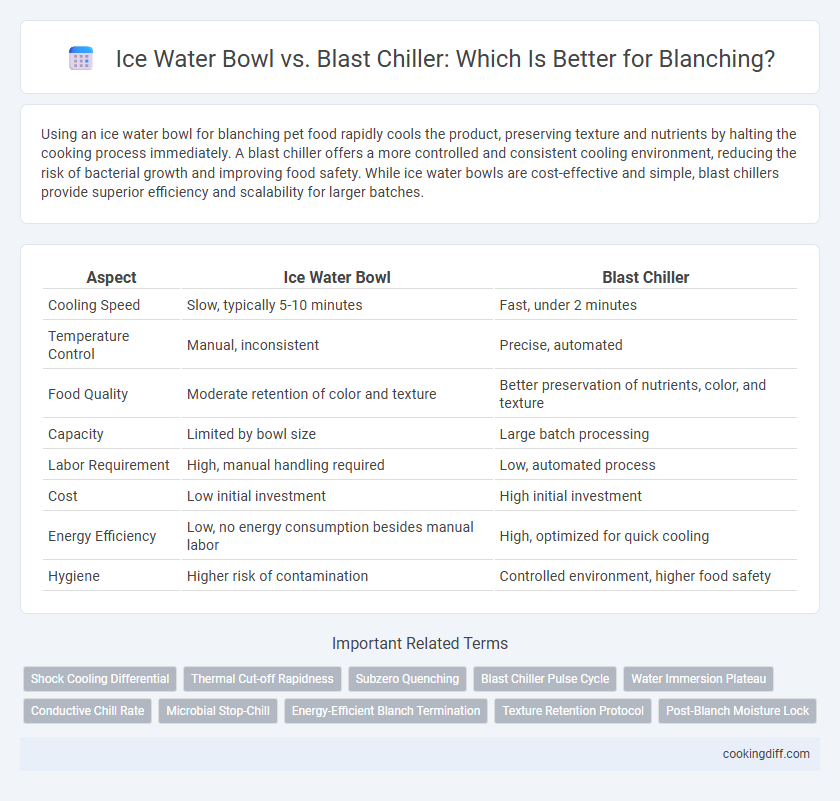

Using an ice water bowl for blanching pet food rapidly cools the product, preserving texture and nutrients by halting the cooking process immediately. A blast chiller offers a more controlled and consistent cooling environment, reducing the risk of bacterial growth and improving food safety. While ice water bowls are cost-effective and simple, blast chillers provide superior efficiency and scalability for larger batches.

Table of Comparison

| Aspect | Ice Water Bowl | Blast Chiller |

|---|---|---|

| Cooling Speed | Slow, typically 5-10 minutes | Fast, under 2 minutes |

| Temperature Control | Manual, inconsistent | Precise, automated |

| Food Quality | Moderate retention of color and texture | Better preservation of nutrients, color, and texture |

| Capacity | Limited by bowl size | Large batch processing |

| Labor Requirement | High, manual handling required | Low, automated process |

| Cost | Low initial investment | High initial investment |

| Energy Efficiency | Low, no energy consumption besides manual labor | High, optimized for quick cooling |

| Hygiene | Higher risk of contamination | Controlled environment, higher food safety |

Introduction: The Role of Rapid Cooling in Blanching

| Rapid cooling after blanching is crucial to halt enzymatic activity and preserve vegetable texture and color. Ice water bowls provide an immediate cold shock by immersing products in near 0degC water, effectively stopping cooking processes. Blast chillers use cold air circulation at temperatures around -1degC to 3degC, offering uniform cooling for large batches while reducing water usage and contamination risk. |

Ice Water Bowl: Traditional Method Explained

The ice water bowl method for blanching involves immediately cooling vegetables in a bowl filled with ice and water after boiling. This traditional technique rapidly halts the cooking process, preserving color, texture, and nutrients effectively.

Using an ice water bowl is cost-effective and simple, ideal for small batches and home kitchens with limited equipment. However, it may be less efficient than a blast chiller for large-scale blanching due to slower cooling times and uneven temperature control.

Blast Chiller: Modern Approach to Blanching

Blast chillers offer a modern approach to blanching by rapidly cooling vegetables, preserving vibrant color and crisp texture more effectively than traditional ice water bowls. This technology minimizes nutrient loss and bacterial growth by quickly lowering the product temperature, ensuring food safety and quality. The precise control over cooling temperature and time provided by blast chillers enhances consistency in food processing compared to manual ice water immersion methods.

Cooling Efficiency: Ice Water vs. Blast Chiller

Ice water bowls cool blanched vegetables by rapidly lowering their temperature, but their efficiency depends on frequent water replacement to maintain coldness. Blast chillers offer superior cooling efficiency by circulating cold air around the food, ensuring uniform and faster temperature reduction.

- Ice Water Bowl Cooling - Requires manual water changes to sustain low temperatures and prevent heat absorption from multiple batches.

- Blast Chiller Efficiency - Uses controlled cold air circulation to cool food evenly and quickly, minimizing bacterial growth risk.

- Energy Consumption - Blast chillers consume more energy but deliver consistent cooling performance compared to ice water bowls.

Impact on Nutrient Retention and Color

Immersing vegetables in an ice water bowl immediately after blanching rapidly cools them, effectively halting the cooking process and preserving vibrant color and nutrient content, especially water-soluble vitamins like vitamin C. This method prevents enzymatic browning, maintaining visual appeal and nutritional quality.

In contrast, a blast chiller cools produce more gradually than ice water, which may result in slight nutrient degradation and color loss due to prolonged exposure to residual heat. The slower cooling rate can lead to diminished antioxidant levels and less crisp, duller vegetables compared to ice water cooling.

Food Safety: Minimizing Bacterial Growth

Immersing blanched vegetables in an ice water bowl rapidly cools them, slowing bacterial growth and maintaining food safety. However, temperature control can be inconsistent, posing potential risks of microbial proliferation.

Blast chillers offer precise and uniform cooling by quickly reducing the temperature of blanched food, effectively minimizing bacterial growth and ensuring higher food safety standards. The rapid temperature drop inhibits pathogen multiplication, which is critical in commercial food processing. Their regulated environment reduces contamination risks compared to manual ice water methods.

Practicality in Home and Commercial Kitchens

Ice water bowls provide a simple and cost-effective method for halting the cooking process after blanching, making them ideal for home kitchens with limited space and budget. Blast chillers offer rapid and uniform cooling, which enhances food safety and quality, suiting the high-volume demands of commercial kitchens.

- Ice Water Bowl Convenience - Requires minimal equipment and countertop space, perfect for casual or small-scale blanching tasks.

- Blast Chiller Efficiency - Cools large quantities quickly, reducing bacterial growth and preserving texture in busy foodservice environments.

- Cost Consideration - Ice water bowls are low-cost and maintenance-free, while blast chillers involve higher initial investment and operating expenses.

Cost and Equipment Considerations

Which method offers a more cost-effective solution for blanching: ice water bowls or blast chillers? Ice water bowls require minimal initial investment and lower maintenance costs, making them suitable for small-scale operations or home use. Blast chillers involve higher upfront equipment expenses but provide faster cooling times and better temperature control, ideal for large-scale commercial kitchens.

Environmental Impacts: Water and Energy Use

Using an ice water bowl for blanching consumes substantial amounts of water and requires continuous ice production, leading to high energy use. Blast chillers minimize water consumption but demand significant electrical energy to rapidly cool products, impacting carbon emissions.

- Water Usage in Ice Water Bowls - Large volumes of water are used and frequently replaced to maintain low temperatures, resulting in considerable water waste.

- Energy Consumption for Ice Production - Freezing water for ice requires substantial electricity, increasing the overall environmental footprint.

- Energy Efficiency of Blast Chillers - While avoiding excessive water use, blast chillers rely heavily on electricity, potentially increasing greenhouse gas emissions depending on energy sources.

Choosing between these methods requires balancing water conservation with energy consumption to reduce environmental impact effectively.

Related Important Terms

Shock Cooling Differential

Ice water bowls provide immediate shock cooling by rapidly lowering the temperature of blanched vegetables to near 0degC, preserving color, texture, and nutritional content effectively. Blast chillers achieve precise control of cooling rates with rapid airflow and temperature regulation, minimizing microbial growth while offering consistent cooling for large-scale blanching operations.

Thermal Cut-off Rapidness

An ice water bowl provides immediate thermal shock to vegetables after blanching, rapidly halting the cooking process and preserving texture and color. A blast chiller, while effective in cooling, operates with slower thermal cut-off times compared to ice water, potentially allowing residual heat to continue softening the produce.

Subzero Quenching

Subzero quenching using an ice water bowl rapidly halts the cooking process by swiftly cooling blanched vegetables to prevent overcooking and preserve texture and nutrients. In contrast, a blast chiller offers controlled, uniform cooling with regulated airflow, improving food safety and consistency but potentially lacking the instantaneous temperature drop of subzero quenching.

Blast Chiller Pulse Cycle

Blast chiller pulse cycles offer precise temperature control and rapid cooling after blanching, significantly reducing bacterial growth and preserving vegetable texture and nutrients compared to traditional ice water bowls. This method enhances food safety and quality by minimizing thermal shock and water uptake commonly associated with ice water chilling.

Water Immersion Plateau

Ice water bowls rapidly halt the cooking process by immersing blanched vegetables in cold water, effectively preventing overcooking and maintaining texture through a sharp temperature drop. Blast chillers cool products more uniformly and quickly, reducing the water immersion plateau time and minimizing nutrient loss compared to traditional ice water methods.

Conductive Chill Rate

An ice water bowl provides a slower conductive chill rate during blanching, which can result in uneven cooling and potential nutrient loss. Blast chillers offer a rapid conductive chill rate, preserving texture and color more effectively by quickly halting the cooking process.

Microbial Stop-Chill

Ice water bowls rapidly cool blanched vegetables by halting enzymatic activity and microbial growth through immediate temperature reduction to below 5degC. Blast chillers provide a more consistent and controlled cooling environment, reducing microbial proliferation more effectively by lowering core temperatures to safe levels within 90 minutes, aligned with HACCP standards.

Energy-Efficient Blanch Termination

An ice water bowl rapidly cools blanched vegetables through direct contact, but consumes significant energy for ice production and maintenance, impacting overall energy efficiency. A blast chiller uses high-velocity cold air to quickly lower product temperature with optimized energy consumption, making it a more energy-efficient option for blanch termination in food processing.

Texture Retention Protocol

Ice water bowls rapidly cool blanched vegetables, preserving cellular structure and texture by halting enzymatic activity; however, blast chillers offer more uniform and controlled cooling, minimizing moisture loss and maintaining optimal firmness according to texture retention protocols. Studies show that blast chilling reduces surface dehydration and enhances crispness better than traditional ice water methods, making it ideal for high-quality blanching processes.

Ice water bowl vs Blast chiller for blanching. Infographic

cookingdiff.com

cookingdiff.com