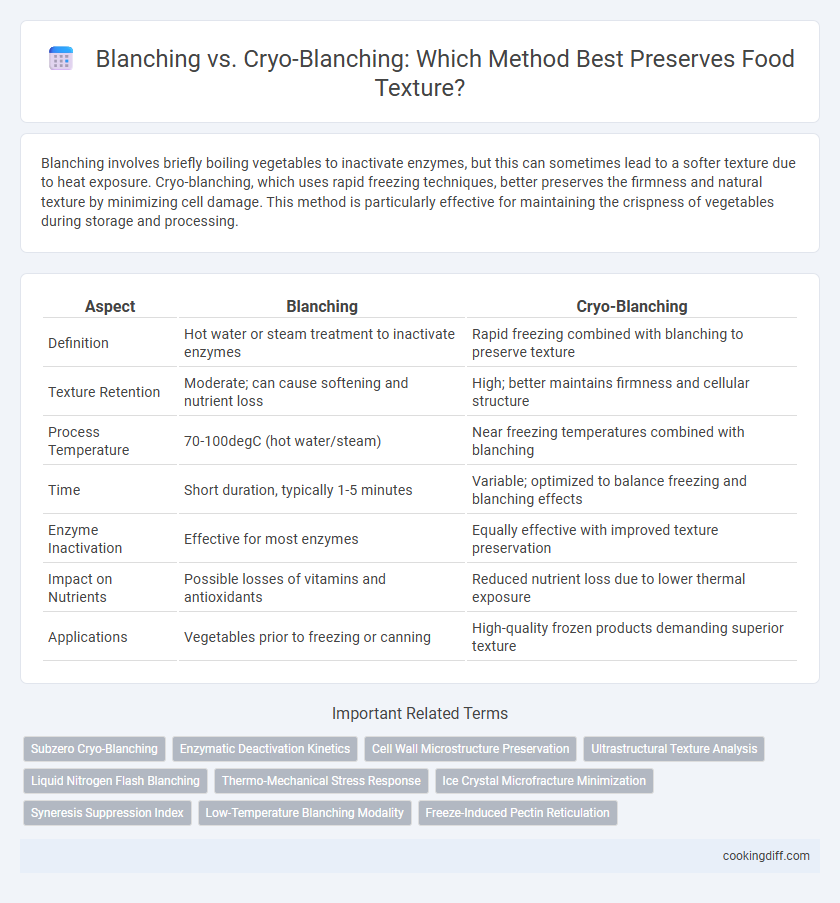

Blanching involves briefly boiling vegetables to inactivate enzymes, but this can sometimes lead to a softer texture due to heat exposure. Cryo-blanching, which uses rapid freezing techniques, better preserves the firmness and natural texture by minimizing cell damage. This method is particularly effective for maintaining the crispness of vegetables during storage and processing.

Table of Comparison

| Aspect | Blanching | Cryo-Blanching |

|---|---|---|

| Definition | Hot water or steam treatment to inactivate enzymes | Rapid freezing combined with blanching to preserve texture |

| Texture Retention | Moderate; can cause softening and nutrient loss | High; better maintains firmness and cellular structure |

| Process Temperature | 70-100degC (hot water/steam) | Near freezing temperatures combined with blanching |

| Time | Short duration, typically 1-5 minutes | Variable; optimized to balance freezing and blanching effects |

| Enzyme Inactivation | Effective for most enzymes | Equally effective with improved texture preservation |

| Impact on Nutrients | Possible losses of vitamins and antioxidants | Reduced nutrient loss due to lower thermal exposure |

| Applications | Vegetables prior to freezing or canning | High-quality frozen products demanding superior texture |

Introduction to Blanching and Cryo-Blanching

Blanching is a heat treatment process where vegetables or fruits are briefly boiled or steamed to inactivate enzymes that cause spoilage. Cryo-blanching involves using ultra-low temperatures, often with liquid nitrogen, to rapidly cool produce and preserve texture.

Blanching improves texture by softening cell walls, but may lead to some nutrient loss and texture changes due to heat exposure. Cryo-blanching enhances texture retention by minimizing thermal damage and preventing enzymatic activity through rapid freezing. This innovative method maintains the crispness and firmness of fruits and vegetables more effectively than traditional blanching.

Understanding Texture Retention in Cooking

Blanching involves briefly boiling vegetables to inactivate enzymes, which helps maintain texture but can cause slight softening due to heat exposure. Cryo-blanching uses ultra-low temperature treatments, preserving cellular integrity and resulting in superior texture retention.

Studies show cryo-blanching minimizes moisture loss and structural damage compared to conventional blanching, enhancing crispness and firmness. This method is especially effective for delicate vegetables where optimal texture is critical for consumer acceptance.

Traditional Blanching: Process and Impact on Texture

Traditional blanching involves briefly immersing vegetables in boiling water or steam to inactivate enzymes that cause spoilage, but this process can lead to a softer texture due to heat exposure. The impact on texture varies with time and temperature, often resulting in some loss of crispness compared to cryo-blanching methods.

- Enzyme Inactivation - Traditional blanching effectively halts enzymatic activity to preserve food quality during storage.

- Texture Softening - Prolonged heat exposure during blanching causes cell wall breakdown, leading to reduced firmness in vegetables.

- Process Control - Precise control of blanching time and temperature is crucial to minimize texture degradation while ensuring microbial safety.

Traditional blanching remains widely used despite texture challenges due to its simplicity and effectiveness in enzyme control.

What Is Cryo-Blanching?

Cryo-blanching is an innovative food processing technique that uses super-cooled air or liquid nitrogen to rapidly cool vegetables, preserving their texture more effectively than traditional blanching. This method minimizes cell damage and water loss, resulting in crisper and fresher produce.

- Rapid cooling - Cryo-blanching employs extremely low temperatures to quickly halt enzymatic activity and maintain structural integrity.

- Enhanced texture retention - The method reduces softening and mushiness commonly caused by conventional hot-water blanching.

- Minimized nutrient loss - By avoiding prolonged heat exposure, cryo-blanching helps preserve vitamins and antioxidants in vegetables.

Comparing Texture Outcomes: Blanching vs Cryo-Blanching

| Method | Texture Retention | Advantages |

|---|---|---|

| Blanching | Moderate firmness; some softening due to heat exposure. | Effective enzymatic inactivation; widely used in food processing. |

| Cryo-Blanching | Superior texture preservation; maintains crispness and cell structure. | Minimizes thermal damage; enhances sensory quality of vegetables. |

Key Factors Affecting Texture Retention

Blanching uses hot water or steam to inactivate enzymes but often causes softening due to heat exposure, impacting texture retention. Cryo-blanching involves brief exposure to low temperatures before blanching, helping preserve cell structure and firmness more effectively.

Key factors affecting texture retention include blanching temperature, duration, and the cooling method used post-treatment. Cryo-blanching reduces thermal degradation and limits moisture loss, resulting in improved crispness and reduced tissue damage compared to conventional blanching.

Nutritional Differences Between Methods

Blanching involves brief exposure to hot water or steam, causing mild nutrient loss, especially of water-soluble vitamins like vitamin C and B-complex. Cryo-blanching uses liquid nitrogen or other cryogenic agents, effectively preserving texture and minimizing nutritional degradation by rapidly cooling and halting enzymatic activity. Studies demonstrate that cryo-blanched vegetables retain higher levels of antioxidants, vitamins, and minerals compared to traditional blanching methods, enhancing overall nutritional quality.

Applications in Home and Industrial Kitchens

How do blanching and cryo-blanching compare in texture retention for home and industrial kitchen applications? Blanching uses hot water or steam to inactivate enzymes, which can soften vegetables but is simple and cost-effective for home use. Cryo-blanching employs ultra-low temperatures with liquid nitrogen, preserving crispness and color, making it ideal for industrial kitchens seeking high-quality texture retention.

Pros and Cons: Blanching vs Cryo-Blanching

Blanching uses hot water or steam to inactivate enzymes, which can soften texture, while cryo-blanching utilizes liquid nitrogen to rapidly cool and preserve firmness. Cryo-blanching offers better texture retention but involves higher operational costs and complexity.

- Blanching softens texture - Heat exposure partially cooks vegetables, leading to a softer texture.

- Cryo-blanching preserves firmness - Rapid cooling with liquid nitrogen maintains cell structure and crispness.

- Cost and complexity - Cryo-blanching requires specialized equipment and higher energy input compared to conventional blanching.

Related Important Terms

Subzero Cryo-Blanching

Subzero Cryo-Blanching significantly enhances texture retention in vegetables by rapidly inactivating enzymes and minimizing cellular damage compared to traditional blanching methods. This technique uses ultra-low temperatures to preserve firmness and crunchiness, resulting in superior quality and extended shelf life for fresh produce.

Enzymatic Deactivation Kinetics

Blanching rapidly deactivates enzymes responsible for tissue degradation, yet Cryo-Blanching enhances enzymatic inactivation kinetics by lowering the temperature and reducing thermal damage, leading to superior texture retention in vegetables. The slowed enzymatic reactions during Cryo-Blanching preserve cell integrity and firmness more effectively than conventional hot water or steam blanching methods.

Cell Wall Microstructure Preservation

Cryo-blanching significantly enhances cell wall microstructure preservation compared to traditional blanching by minimizing thermal degradation and maintaining cellular integrity. This method results in superior texture retention in vegetables, as it better preserves pectin substances and reduces cell wall rupture during processing.

Ultrastructural Texture Analysis

Cryo-blanching preserves ultrastructural integrity by maintaining cell wall rigidity and reducing pectin degradation compared to traditional blanching, which often causes cellular collapse and gelatinization. Ultrastructural texture analysis reveals that cryo-blanched samples retain higher firmness and crispness due to minimized enzymatic activity and better moisture retention at the microscopic level.

Liquid Nitrogen Flash Blanching

Liquid Nitrogen Flash Blanching significantly enhances texture retention in vegetables by rapidly cooling them, preventing cell wall breakdown and maintaining firmness compared to traditional hot water blanching. This cryo-blanching method minimizes enzymatic activity and moisture loss, resulting in superior crispness and color preservation.

Thermo-Mechanical Stress Response

Blanching causes significant thermo-mechanical stress leading to cell wall softening and texture degradation, while cryo-blanching minimizes this stress by rapidly lowering temperature, preserving cell turgor and firmness. Studies show cryo-blanching enhances texture retention by reducing enzymatic activity without compromising structural integrity during subsequent processing.

Ice Crystal Microfracture Minimization

Cryo-blanching significantly reduces ice crystal microfracture formation compared to traditional blanching, preserving cellular integrity and enhancing texture retention in frozen vegetables. Minimizing microfractures prevents excessive moisture loss during thawing, resulting in a firmer, more desirable mouthfeel.

Syneresis Suppression Index

Cryo-blanching significantly enhances texture retention by maintaining higher Syneresis Suppression Index values compared to traditional blanching, effectively minimizing water loss and preserving cellular integrity in fruits and vegetables. Studies demonstrate that cryo-blanching reduces syneresis by up to 30%, leading to firmer texture and improved post-processing quality.

Low-Temperature Blanching Modality

Low-temperature blanching, including cryo-blanching, significantly enhances texture retention by minimizing cell wall degradation and enzyme activity compared to conventional high-temperature blanching. Cryo-blanching, utilizing sub-zero temperatures, better preserves firmness and reduces nutrient leaching in vegetables, optimizing quality for frozen and fresh produce applications.

Blanching vs Cryo-Blanching for texture retention Infographic

cookingdiff.com

cookingdiff.com