Blanching effectively deactivates enzymes by exposing food to hot water or steam for a short duration, preserving color, texture, and nutritional quality. Instantaneous Thermal Processing (ITP), using rapid and precise high-temperature treatments, achieves enzyme deactivation more quickly and uniformly, reducing nutrient loss and improving shelf life. Comparing both methods, ITP offers enhanced efficiency and better preservation of sensory attributes, making it suitable for high-quality food processing.

Table of Comparison

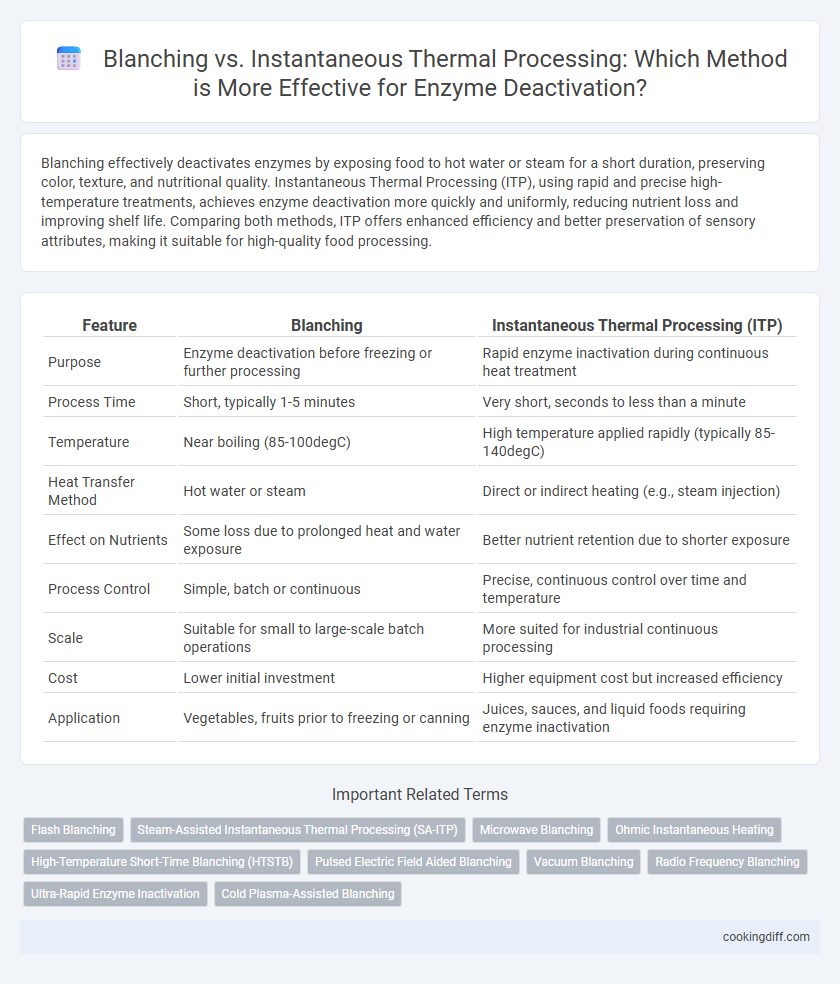

| Feature | Blanching | Instantaneous Thermal Processing (ITP) |

|---|---|---|

| Purpose | Enzyme deactivation before freezing or further processing | Rapid enzyme inactivation during continuous heat treatment |

| Process Time | Short, typically 1-5 minutes | Very short, seconds to less than a minute |

| Temperature | Near boiling (85-100degC) | High temperature applied rapidly (typically 85-140degC) |

| Heat Transfer Method | Hot water or steam | Direct or indirect heating (e.g., steam injection) |

| Effect on Nutrients | Some loss due to prolonged heat and water exposure | Better nutrient retention due to shorter exposure |

| Process Control | Simple, batch or continuous | Precise, continuous control over time and temperature |

| Scale | Suitable for small to large-scale batch operations | More suited for industrial continuous processing |

| Cost | Lower initial investment | Higher equipment cost but increased efficiency |

| Application | Vegetables, fruits prior to freezing or canning | Juices, sauces, and liquid foods requiring enzyme inactivation |

Introduction to Enzyme Deactivation in Food Processing

How do blanching and instantaneous thermal processing compare in enzyme deactivation during food processing? Blanching involves briefly exposing food to boiling water or steam to inactivate enzymes, primarily targeting peroxidase and polyphenol oxidase to preserve color and texture. Instantaneous thermal processing uses rapid, high-temperature treatments that achieve faster enzyme inactivation, minimizing nutrient loss and improving product quality.

Understanding Blanching: Method and Mechanism

Blanching is a thermal process involving brief exposure of food to hot water or steam to inactivate enzymes, preserving color, flavor, and texture. It primarily targets enzymes like peroxidase and polyphenol oxidase through heat-induced denaturation, preventing enzymatic browning and spoilage. Compared to Instantaneous Thermal Processing, blanching uses comparatively lower temperatures and longer times, balancing effective enzyme deactivation with minimal nutrient loss.

Instantaneous Thermal Processing: An Overview

Instantaneous Thermal Processing (ITP) offers rapid and uniform enzyme deactivation by subjecting food products to high temperatures for a very brief duration, often milliseconds to seconds. This method preserves nutritional quality and sensory attributes better than traditional blanching due to minimized thermal exposure.

ITP technology utilizes advanced heat exchangers and precise temperature controls to achieve effective microbial and enzyme inactivation. Its application enhances shelf life and safety while maintaining the structural integrity and color of fresh produce compared to conventional blanching techniques.

Comparative Efficiency: Blanching vs Instantaneous Thermal Processing

Blanching and Instantaneous Thermal Processing (ITP) both effectively deactivate enzymes, but ITP offers superior precision and reduced nutrient loss due to rapid heating and cooling cycles. Blanching typically requires longer exposure to heat, which can lead to diminished texture and flavor quality in some vegetables.

- Blanching Efficiency - Uses hot water or steam for a fixed time, ensuring enzyme inactivation but with potential nutrient degradation.

- Instantaneous Thermal Processing Efficiency - Employs rapid heating and cooling, minimizing thermal damage while achieving enzyme deactivation.

- Comparative Energy Use - ITP generally consumes less energy overall due to shorter processing times compared to blanching.

Instantaneous Thermal Processing presents a more energy-efficient and nutrient-preserving enzyme deactivation method compared to traditional blanching.

Nutrient Retention: Which Method Preserves More?

Blanching partially deactivates enzymes but often results in higher nutrient loss due to longer exposure to heat and water. Instantaneous thermal processing (ITP) rapidly inactivates enzymes while better preserving vitamins and antioxidants because of its shorter processing time.

- Blanching involves hot water or steam - This traditional method exposes produce to heat for several minutes, causing leaching of water-soluble nutrients like vitamin C.

- Instantaneous thermal processing uses rapid heating and cooling - ITP minimizes nutrient degradation by reducing thermal exposure time, thus maintaining more of the food's natural nutrient profile.

- Studies show ITP preserves more nutrients - Research indicates that ITP-treated vegetables retain higher levels of antioxidants and vitamins compared to those subjected to blanching.

Impact on Food Texture and Color

Blanching effectively deactivates enzymes by applying moderate heat briefly, which preserves food texture and color moderately well. Instantaneous Thermal Processing (ITP) uses rapid, high-temperature treatments that minimize texture degradation and better retain vibrant color compared to traditional blanching.

- Blanching preserves texture - It softens cell walls which can lead to slight loss of crispness in vegetables.

- ITP enhances color retention - Rapid heating limits pigment degradation, maintaining brighter colors.

- Enzyme deactivation efficiency - ITP achieves faster and more uniform enzyme inactivation, improving overall food quality.

Energy Consumption and Cost Analysis

| Process | Energy Consumption (kWh/kg) | Cost Analysis (USD/kg) |

|---|---|---|

| Blanching | 0.15 - 0.25 | 0.12 - 0.18 |

| Instantaneous Thermal Processing (ITP) | 0.05 - 0.10 | 0.08 - 0.13 |

Instantaneous Thermal Processing exhibits notably lower energy consumption compared to traditional blanching methods, with values averaging below 0.10 kWh/kg. Cost analysis indicates that ITP reduces operational expenses by up to 30% due to decreased energy demands and shorter processing times. These factors make ITP a more cost-effective and energy-efficient option for enzyme deactivation in food processing.

Suitability for Different Food Types

Blanching effectively deactivates enzymes in vegetables such as green beans and broccoli by applying hot water or steam, preserving color and texture while preparing them for freezing or further processing. Instantaneous Thermal Processing (ITP) is better suited for liquid foods like fruit juices and purees, providing rapid enzyme inactivation without compromising nutritional quality. The choice between blanching and ITP depends on the food matrix, with blanching favored for solid, heat-tolerant products and ITP for heat-sensitive, fluid items.

Industrial Applications and Scalability

Blanching is widely used in industrial applications for enzyme deactivation due to its simplicity and cost-effectiveness, making it suitable for large-scale vegetable and fruit processing. Its scalability is proven in continuous blanching systems that handle high throughput volumes with consistent temperature control.

Instantaneous Thermal Processing (ITP) offers precise enzyme inactivation through rapid heating and cooling, minimizing nutrient loss and improving product quality. Although scalability is more challenging than blanching, recent advancements in ITP equipment enable integration into industrial food production lines with high efficiency.

Related Important Terms

Flash Blanching

Flash blanching rapidly heats vegetables to 70-90degC for 30 seconds to 2 minutes, effectively inactivating enzymes like peroxidase and polyphenol oxidase while preserving texture and nutrients better than conventional blanching. Compared to instantaneous thermal processing, flash blanching offers quicker temperature elevation and shorter exposure time, minimizing quality degradation while ensuring enzymatic stability.

Steam-Assisted Instantaneous Thermal Processing (SA-ITP)

Steam-Assisted Instantaneous Thermal Processing (SA-ITP) provides rapid and uniform enzyme deactivation by applying high-temperature steam for a controlled short duration, minimizing nutrient loss compared to traditional blanching. This technique enhances the preservation of food quality attributes while ensuring effective inactivation of heat-sensitive enzymes such as peroxidase and polyphenol oxidase.

Microwave Blanching

Microwave blanching offers rapid and uniform enzyme deactivation by utilizing dielectric heating, which penetrates food matrices more efficiently than traditional blanching methods. Compared to instantaneous thermal processing, microwave blanching reduces processing time and nutrient loss while maintaining better texture and color retention in vegetables.

Ohmic Instantaneous Heating

Ohmic instantaneous heating enhances enzyme deactivation by applying rapid, uniform electric currents that quickly raise product temperature, preserving nutritional quality more effectively than traditional blanching. This method minimizes thermal gradients and processing time, improving efficiency and retaining texture and color in food products.

High-Temperature Short-Time Blanching (HTSTB)

High-Temperature Short-Time Blanching (HTSTB) effectively deactivates enzymes by applying rapid heating, minimizing nutrient loss and preserving food quality compared to conventional blanching methods. Instantaneous Thermal Processing (ITP) achieves enzyme inactivation through ultra-rapid heating and cooling, but HTSTB offers a balance between thermal efficiency and practical scalability for industrial applications.

Pulsed Electric Field Aided Blanching

Pulsed Electric Field (PEF) aided blanching enhances enzyme deactivation by causing targeted cell membrane permeabilization, leading to more efficient thermal diffusion compared to conventional blanching methods. This approach reduces processing time and thermal damage while preserving food quality, outperforming Instantaneous Thermal Processing (ITP) in maintaining nutritional and sensory attributes during enzyme inactivation.

Vacuum Blanching

Vacuum blanching effectively deactivates enzymes by reducing the boiling point of water, minimizing thermal damage and preserving nutritional and sensory qualities compared to conventional blanching methods. Instantaneous thermal processing achieves rapid enzyme inactivation through high temperatures but may cause uneven heat distribution, whereas vacuum blanching ensures uniform heating under reduced pressure, enhancing product quality and enzyme deactivation efficiency.

Radio Frequency Blanching

Radio Frequency (RF) Blanching offers rapid, uniform enzyme inactivation by generating volumetric heating, outperforming conventional blanching methods in preserving food quality and nutrient retention. Compared to Instantaneous Thermal Processing, RF blanching reduces processing time and energy consumption while effectively deactivating enzymes such as peroxidase and polyphenol oxidase.

Ultra-Rapid Enzyme Inactivation

Ultra-rapid enzyme inactivation through instantaneous thermal processing achieves enzyme deactivation in milliseconds, significantly reducing nutrient loss compared to traditional blanching methods, which require longer exposure to heat. This precision thermal control optimizes enzyme inactivation while preserving food quality, texture, and color more effectively than conventional blanching.

Blanching vs Instantaneous Thermal Processing for enzyme deactivation Infographic

cookingdiff.com

cookingdiff.com