Blanching involves briefly boiling or steaming vegetables to inactivate enzymes and preserve color, while fluidized-bed drying uses hot air to reduce moisture content efficiently during par-cooking. Fluidized-bed drying offers uniform heat distribution and faster drying times compared to blanching, which mainly serves as a pre-treatment step. Choosing between blanching and fluidized-bed drying depends on the desired texture, nutrient retention, and processing speed for the par-cooked product.

Table of Comparison

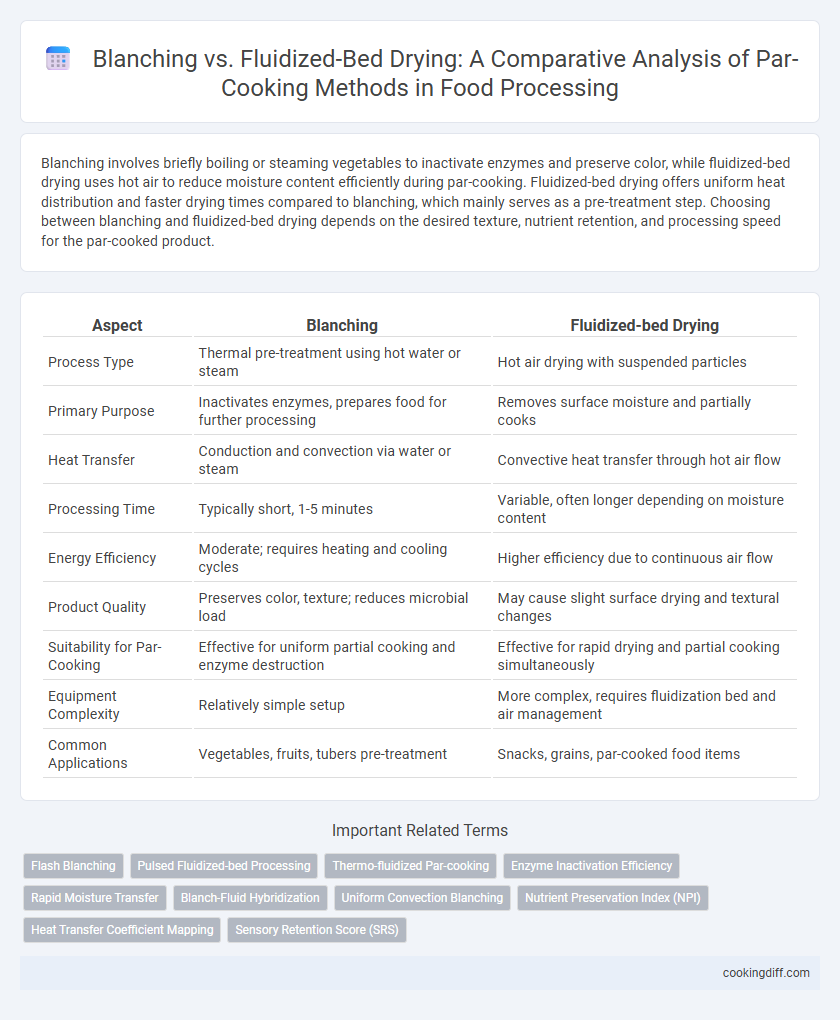

| Aspect | Blanching | Fluidized-bed Drying |

|---|---|---|

| Process Type | Thermal pre-treatment using hot water or steam | Hot air drying with suspended particles |

| Primary Purpose | Inactivates enzymes, prepares food for further processing | Removes surface moisture and partially cooks |

| Heat Transfer | Conduction and convection via water or steam | Convective heat transfer through hot air flow |

| Processing Time | Typically short, 1-5 minutes | Variable, often longer depending on moisture content |

| Energy Efficiency | Moderate; requires heating and cooling cycles | Higher efficiency due to continuous air flow |

| Product Quality | Preserves color, texture; reduces microbial load | May cause slight surface drying and textural changes |

| Suitability for Par-Cooking | Effective for uniform partial cooking and enzyme destruction | Effective for rapid drying and partial cooking simultaneously |

| Equipment Complexity | Relatively simple setup | More complex, requires fluidization bed and air management |

| Common Applications | Vegetables, fruits, tubers pre-treatment | Snacks, grains, par-cooked food items |

Introduction to Blanching and Fluidized-Bed Drying

Blanching is a short heat treatment process used to inactivate enzymes and preserve color, texture, and nutritional value in vegetables before further processing. Fluidized-bed drying involves passing hot air through a bed of particles, efficiently removing moisture while maintaining product quality.

In par-cooking, blanching primarily serves as a preparatory step to ensure even cooking and extend shelf life by reducing microbial load. Fluidized-bed drying offers uniform drying, quick moisture removal, and improved energy efficiency compared to traditional drying methods. Combining blanching with fluidized-bed drying optimizes texture retention and reduces processing time in food production.

Understanding the Par-Cooking Process

Blanching involves briefly boiling vegetables to inactivate enzymes and preserve color, texture, and nutritional quality during par-cooking. Fluidized-bed drying rapidly removes surface moisture through hot air circulation, enhancing product stability while partially cooking the food. Understanding the par-cooking process requires comparing the enzyme inactivation efficiency of blanching with the moisture reduction and heat transfer benefits of fluidized-bed drying.

Key Differences Between Blanching and Fluidized-Bed Drying

| Aspect | Blanching | Fluidized-Bed Drying |

|---|---|---|

| Process Type | Thermal treatment involving short-time immersion in hot water or steam to inactivate enzymes. | Drying method using hot air fluidized by a gas flow to remove moisture from par-cooked products. |

| Primary Purpose | Enzyme inactivation and microbial reduction to improve shelf life and color retention. | Moisture removal to reduce drying time and improve product texture and shelf stability. |

| Impact on Texture | Softens texture due to heat exposure, potentially affecting firmness. | Maintains or enhances firmness by rapid drying and minimal thermal damage. |

| Energy Consumption | Moderate energy use primarily for heating water or steam generation. | Higher energy demand due to continuous hot air flow and fluidization equipment. |

| Application in Par-Cooking | Commonly used as a pretreatment to preserve color and reduce microbial load before packaging or further cooking. | Used to par-cook and partially dehydrate products simultaneously, improving shelf life and reducing post-cooking time. |

Advantages of Blanching for Par-Cooking

Blanching preserves the vibrant color and texture of vegetables better than fluidized-bed drying due to its rapid heat penetration and enzymatic inactivation. It enhances food safety by effectively reducing surface microbial load before par-cooking. The process also minimizes nutrient loss, particularly water-soluble vitamins, making it ideal for maintaining product quality during subsequent par-cooking stages.

Benefits of Fluidized-Bed Drying in Par-Cooking

Fluidized-bed drying offers superior heat and mass transfer rates compared to traditional blanching, enabling more uniform par-cooking. This technology reduces processing time and preserves nutritional quality while enhancing moisture removal efficiency.

- Enhanced Uniformity - Fluidized beds provide consistent drying by suspending particles, which prevents localized overheating and ensures even par-cooking.

- Energy Efficiency - Faster drying cycles reduce energy consumption, lowering operational costs for food processing facilities.

- Nutrient Retention - The controlled drying environment minimizes nutrient loss, maintaining higher vitamin and antioxidant levels in the final product.

Impact on Nutritional Quality and Product Texture

Blanching preserves color and inhibits enzymatic activity, but often results in nutrient loss, particularly vitamins sensitive to heat and water. Fluidized-bed drying retains more nutrients and enhances product texture by reducing moisture uniformly without water immersion.

- Nutrient Retention - Fluidized-bed drying minimizes leaching of water-soluble vitamins compared to blanching, preserving higher nutritional quality.

- Texture Impact - Blanching can soften cell structure, potentially causing texture degradation, whereas fluidized-bed drying maintains firmness and crispness.

- Processing Efficiency - Fluidized-bed drying offers rapid moisture removal that supports par-cooking while improving shelf-life and sensory attributes.

Energy Efficiency and Cost Comparison

How do blanching and fluidized-bed drying compare in terms of energy efficiency and cost for par-cooking? Blanching typically consumes less energy due to shorter processing times and lower temperature requirements, making it more cost-effective in small to medium scale operations. Fluidized-bed drying offers consistent heat distribution and faster moisture removal but generally incurs higher energy costs and equipment investment, impacting overall operational expenses.

Suitability for Various Food Types

Blanching is highly suitable for vegetables and fruits that require rapid enzyme inactivation and color retention, especially leafy greens and root vegetables. Fluidized-bed drying, on the other hand, excels in par-cooking products with irregular shapes or porous structures, such as pasta and small meat pieces, due to its uniform heat distribution and gentle drying process.

Vegetables like green beans and asparagus benefit from blanching as it preserves texture and nutritional content before freezing or further processing. Fluidized-bed drying is more effective for heat-sensitive foods, minimizing nutrient loss while achieving precise moisture reduction, making it preferable for snack foods and ready-to-eat meals.

Industrial Applications and Scalability

Blanching is widely used in industrial applications for par-cooking due to its efficiency in enzyme inactivation and color retention, making it suitable for large-scale vegetable processing. The process is easily scalable with continuous blanching systems accommodating high throughput volumes in diverse food production facilities.

Fluidized-bed drying offers enhanced heat and mass transfer, enabling uniform par-cooking and drying of products with reduced processing times, which is advantageous in industrial settings aiming for energy efficiency. Scalability is achieved through modular design of fluidized-bed dryers, allowing customization to various production capacities and integration with automated processing lines.

Related Important Terms

Flash Blanching

Flash blanching offers rapid enzyme inactivation with minimal nutrient loss compared to traditional blanching, improving the quality of par-cooked vegetables. When combined with fluidized-bed drying, flash blanching enhances heat transfer efficiency and reduces drying time, resulting in better texture retention and energy savings.

Pulsed Fluidized-bed Processing

Pulsed Fluidized-bed Processing enhances par-cooking by delivering uniform heat transfer and minimizing nutrient loss compared to traditional blanching, which often causes excessive water absorption and enzyme activity. This method's intermittent airflow increases drying efficiency and product quality, making it a superior alternative for maintaining texture and color during fluidized-bed drying.

Thermo-fluidized Par-cooking

Thermo-fluidized par-cooking offers enhanced heat and mass transfer compared to traditional blanching, resulting in more uniform cooking and improved preservation of texture and nutrients. The fluidized-bed drying method reduces processing time and energy consumption while maintaining product quality through efficient temperature control and moisture removal.

Enzyme Inactivation Efficiency

Blanching achieves higher enzyme inactivation efficiency for par-cooking by rapidly denaturing enzymes like polyphenol oxidase and peroxidase through direct heat treatment, ensuring reduced enzymatic browning and prolonged shelf life. Fluidized-bed drying, while effective for moisture reduction, generally provides less uniform enzyme inactivation, leading to potential residual enzymatic activity that may affect product quality.

Rapid Moisture Transfer

Blanching initiates rapid moisture transfer by quickly heating the surface of vegetables, which softens cell walls and facilitates water removal during subsequent drying steps. Fluidized-bed drying enhances rapid moisture transfer through intense air circulation around particles, promoting uniform heat and mass transfer that significantly reduces drying time in par-cooking processes.

Blanch-Fluid Hybridization

Blanch-Fluid hybridization combines the thermal inactivation advantages of blanching with the rapid moisture removal efficiency of fluidized-bed drying, enhancing par-cooking quality and processing speed. This integrated method improves enzymatic stability and texture retention while reducing overall energy consumption compared to conventional single-method treatments.

Uniform Convection Blanching

Uniform Convection Blanching ensures even heat distribution and enzymatic inactivation in par-cooking, enhancing product quality compared to Fluidized-bed drying which may cause uneven surface drying and textural inconsistencies. This method optimizes moisture content and preserves nutrients, making it superior for maintaining color, texture, and flavor in vegetables during the par-cooking process.

Nutrient Preservation Index (NPI)

Blanching significantly enhances the Nutrient Preservation Index (NPI) by deactivating enzymes that cause nutrient degradation, whereas fluidized-bed drying may lead to greater nutrient loss due to prolonged heat exposure. Studies reveal blanching maintains higher levels of vitamins and antioxidants in par-cooked vegetables compared to fluidized-bed drying, optimizing nutrient retention.

Heat Transfer Coefficient Mapping

Heat transfer coefficient mapping reveals that fluidized-bed drying offers more uniform and higher heat transfer rates compared to blanching for par-cooking, enhancing energy efficiency and product quality. Blanching exhibits localized heat transfer variability due to water immersion, whereas fluidized-bed drying ensures consistent convective heat transfer by maintaining optimal airflow dynamics around the product.

Blanching vs Fluidized-bed drying for par-cooking. Infographic

cookingdiff.com

cookingdiff.com