Blanching is a traditional method that uses high-temperature steam or hot water to inactivate enzymes and reduce microbial load, ensuring food safety. Pulsed Electric Field (PEF) blanching, a non-thermal technique, uses short bursts of high voltage to disrupt microbial cell membranes while preserving food quality and nutrients. Compared to conventional blanching, PEF offers enhanced microbial inactivation with minimal heat damage, making it a promising alternative for safer, fresher food products.

Table of Comparison

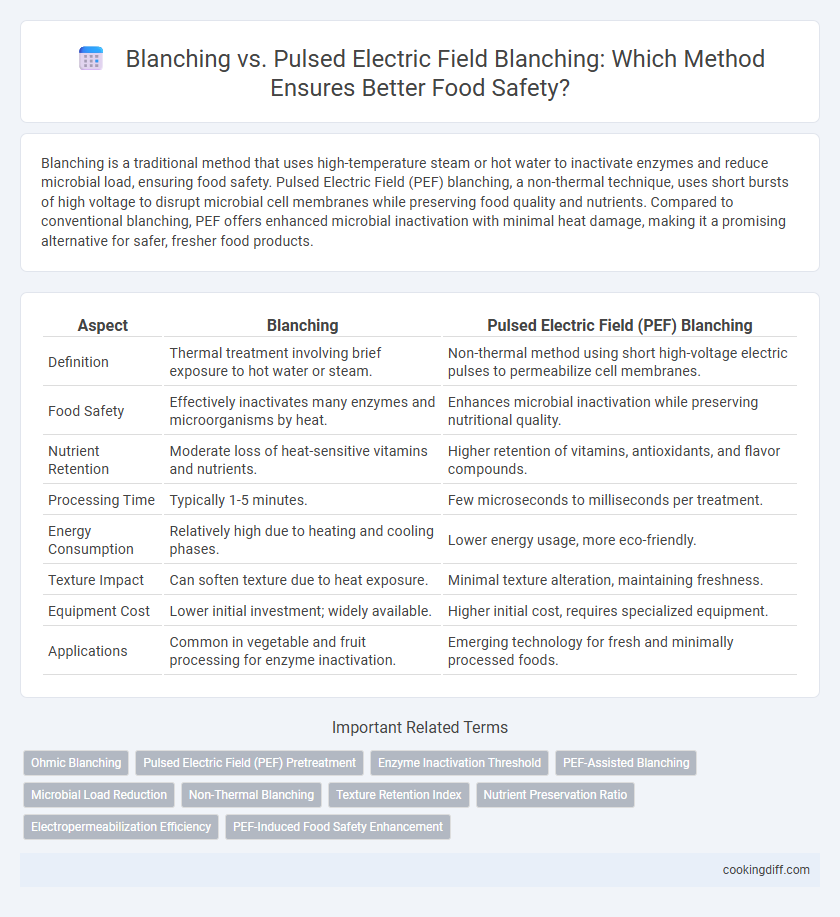

| Aspect | Blanching | Pulsed Electric Field (PEF) Blanching |

|---|---|---|

| Definition | Thermal treatment involving brief exposure to hot water or steam. | Non-thermal method using short high-voltage electric pulses to permeabilize cell membranes. |

| Food Safety | Effectively inactivates many enzymes and microorganisms by heat. | Enhances microbial inactivation while preserving nutritional quality. |

| Nutrient Retention | Moderate loss of heat-sensitive vitamins and nutrients. | Higher retention of vitamins, antioxidants, and flavor compounds. |

| Processing Time | Typically 1-5 minutes. | Few microseconds to milliseconds per treatment. |

| Energy Consumption | Relatively high due to heating and cooling phases. | Lower energy usage, more eco-friendly. |

| Texture Impact | Can soften texture due to heat exposure. | Minimal texture alteration, maintaining freshness. |

| Equipment Cost | Lower initial investment; widely available. | Higher initial cost, requires specialized equipment. |

| Applications | Common in vegetable and fruit processing for enzyme inactivation. | Emerging technology for fresh and minimally processed foods. |

Introduction to Blanching in Food Safety

Blanching is a traditional food processing technique involving short-term exposure to hot water or steam to inactivate enzymes and reduce microbial load, thereby enhancing food safety and shelf life. It primarily targets enzymes such as polyphenol oxidase and peroxidase that cause spoilage and quality degradation in fruits and vegetables.

Pulsed Electric Field (PEF) blanching uses short bursts of high voltage to permeabilize microbial cell membranes, offering an innovative alternative to conventional blanching. PEF maintains better nutritional and sensory qualities while providing effective microbial inactivation for safer food products.

Overview of Conventional Blanching Methods

Conventional blanching methods typically involve immersing or steaming food at temperatures ranging from 70degC to 100degC for short durations to inactivate enzymes and reduce microbial load. These processes are essential for preserving color, texture, and nutritional quality while enhancing food safety by slowing enzymatic activity and destroying surface pathogens.

Traditional blanching may cause nutrient leaching, particularly water-soluble vitamins, and sometimes leads to textural softening due to thermal exposure. Despite these drawbacks, it remains a widely used technique in the food industry due to its simplicity, cost-effectiveness, and proven efficacy in microbial control.

What is Pulsed Electric Field (PEF) Blanching?

Pulsed Electric Field (PEF) blanching is a non-thermal food processing technique that uses short bursts of high voltage electric pulses to inactivate microorganisms and enzymes. This method preserves the texture, color, and nutritional value of food better than traditional blanching, which relies on heat. PEF blanching enhances food safety while maintaining sensory and quality attributes in fruits and vegetables.

Mechanisms of Heat vs. Electric Field Blanching

Traditional blanching employs heat to inactivate enzymes and reduce microbial load by denaturing proteins and disrupting cell membranes through thermal energy. Pulsed Electric Field (PEF) blanching uses short bursts of high voltage to permeabilize cell membranes via electroporation, enhancing microbial inactivation without extensive heat application.

Heat blanching relies on the conduction and convection of thermal energy within food tissues, causing irreversible protein denaturation and enzyme inactivation crucial for food safety. In contrast, PEF induces electric breakdown of cellular membranes, facilitating rapid microbial inactivation while preserving food nutrients and texture. The non-thermal nature of PEF blanching reduces thermal degradation, offering a novel mechanism compared to heat-based processes.

Microbial Inactivation: Traditional vs. PEF Blanching

Traditional blanching involves immersing food in hot water or steam to inactivate microorganisms through heat, effectively reducing microbial load but sometimes compromising nutrient quality. Pulsed Electric Field (PEF) blanching utilizes short bursts of high voltage to disrupt microbial cell membranes, achieving significant microbial inactivation at lower temperatures and preserving food texture and nutrients. Studies demonstrate PEF blanching offers enhanced microbial safety with reduced thermal damage compared to conventional blanching methods.

Impact on Nutrient Retention: Comparing Both Methods

Blanching typically causes significant loss of water-soluble vitamins, particularly vitamin C, due to heat exposure. Pulsed Electric Field (PEF) blanching preserves more nutrients by using short electrical pulses that minimize thermal degradation.

- Vitamin retention - PEF blanching retains up to 80% more vitamin C compared to traditional blanching.

- Antioxidant levels - Antioxidants such as polyphenols degrade less under PEF treatment than thermal blanching.

- Enzyme inactivation - Both methods effectively inactivate enzymes, but PEF achieves this with less nutrient loss.

Effects on Food Texture and Color

Blanching typically causes softening of food texture and slight color fading due to heat exposure, whereas Pulsed Electric Field (PEF) blanching preserves firmness and vibrant color by using short electrical pulses. PEF treatment enhances cell membrane permeability without significant thermal damage, maintaining the natural appearance and crispness of food items.

- Texture Preservation - PEF blanching maintains a firmer texture compared to traditional heat blanching, which often softens produce.

- Color Retention - Foods treated with PEF exhibit better retention of natural color pigments, reducing browning and blanching-induced discoloration.

- Minimal Thermal Impact - PEF's non-thermal mechanism minimizes nutrient loss and preserves sensory attributes.

Choosing PEF blanching over conventional methods significantly improves the visual and textural quality of processed foods.

Energy Efficiency and Environmental Considerations

| Method | Energy Efficiency | Environmental Considerations |

|---|---|---|

| Blanching | Requires high thermal energy for heating water, leading to significant energy consumption. | Generates wastewater containing organic residues and consumes large volumes of water, posing environmental disposal challenges. |

| Pulsed Electric Field Blanching | Utilizes short bursts of high voltage electricity, significantly reducing energy use compared to traditional thermal blanching. | Minimizes water usage and wastewater production, offering a more sustainable and eco-friendly alternative. |

Industrial Applications and Scalability

How do blanching and pulsed electric field blanching compare in industrial applications and scalability for food safety? Traditional blanching is widely used in food processing due to its simplicity, cost-effectiveness, and proven ability to inactivate enzymes and microbes at scale. Pulsed electric field (PEF) blanching offers enhanced food quality retention and energy efficiency but requires significant initial investment and advanced technology for large-scale implementation.

Related Important Terms

Ohmic Blanching

Ohmic blanching uses electrical resistance heating to uniformly and rapidly inactivate enzymes and pathogens, enhancing food safety while preserving sensory quality better than traditional blanching. Compared to pulsed electric field blanching, ohmic blanching offers precise temperature control and uniform heat distribution, reducing nutrient loss and microbial load more effectively in processed foods.

Pulsed Electric Field (PEF) Pretreatment

Pulsed Electric Field (PEF) pretreatment enhances food safety by inactivating microorganisms more effectively than traditional blanching, preserving nutritional quality and sensory attributes. PEF technology applies short bursts of high voltage to disrupt microbial cell membranes, reducing thermal damage and extending shelf life in various food products.

Enzyme Inactivation Threshold

Blanching achieves enzyme inactivation by exposing food to temperatures typically between 70degC and 100degC for short durations, effectively reducing microbial load and preserving texture. Pulsed Electric Field (PEF) blanching inactivates enzymes at lower temperatures through high-voltage electrical pulses, minimizing nutrient loss while ensuring microbial safety and extending shelf life.

PEF-Assisted Blanching

PEF-assisted blanching enhances food safety by using short bursts of high voltage to disrupt microbial cell membranes, preserving nutritional quality and reducing thermal damage compared to conventional blanching. This method improves enzyme inactivation and microbial reduction, resulting in safer, fresher-tasting foods with extended shelf life.

Microbial Load Reduction

Blanching effectively reduces microbial load by using hot water or steam to inactivate spoilage and pathogenic microorganisms in food products. Pulsed Electric Field (PEF) blanching offers a non-thermal alternative that disrupts microbial cell membranes through high-voltage pulses, enhancing food safety while preserving nutritional and sensory qualities better than traditional blanching methods.

Non-Thermal Blanching

Non-thermal blanching methods like Pulsed Electric Field (PEF) blanching preserve food quality by inactivating enzymes without heat-induced nutrient loss or texture degradation common in traditional blanching. PEF blanching enhances microbial safety and retains vitamins, antioxidants, and color better than conventional hot water blanching, proving highly effective for extending shelf life while maintaining food sensory attributes.

Texture Retention Index

Blanching causes significant texture degradation due to heat exposure, resulting in a lower Texture Retention Index compared to Pulsed Electric Field (PEF) blanching, which preserves cellular integrity by using non-thermal electric pulses. PEF blanching achieves higher Texture Retention Index values, enhancing crispness and firmness in vegetables while maintaining food safety standards.

Nutrient Preservation Ratio

Blanching traditionally uses hot water or steam to inactivate enzymes, but it often leads to significant nutrient loss, especially water-soluble vitamins like Vitamin C. Pulsed Electric Field Blanching, by employing short bursts of high voltage, achieves enzyme inactivation with minimal heat, resulting in a higher nutrient preservation ratio, often retaining up to 90% more bioactive compounds compared to conventional blanching methods.

Electropermeabilization Efficiency

Pulsed Electric Field (PEF) blanching significantly enhances electropermeabilization efficiency compared to traditional thermal blanching by using high-voltage pulses to disrupt cell membranes without extensive heat, preserving food texture and nutrient content. This non-thermal method increases microbial inactivation rates and enzyme deactivation while maintaining food quality, offering a safer and more energy-efficient alternative for food safety processing.

Blanching vs Pulsed Electric Field Blanching for food safety. Infographic

cookingdiff.com

cookingdiff.com