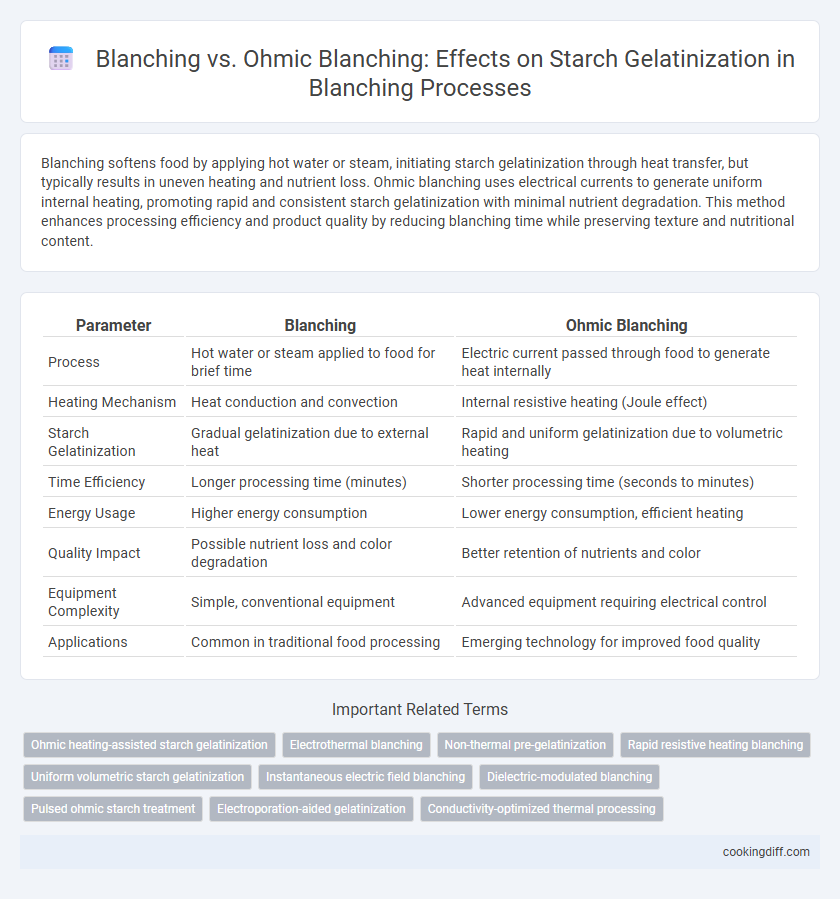

Blanching softens food by applying hot water or steam, initiating starch gelatinization through heat transfer, but typically results in uneven heating and nutrient loss. Ohmic blanching uses electrical currents to generate uniform internal heating, promoting rapid and consistent starch gelatinization with minimal nutrient degradation. This method enhances processing efficiency and product quality by reducing blanching time while preserving texture and nutritional content.

Table of Comparison

| Parameter | Blanching | Ohmic Blanching |

|---|---|---|

| Process | Hot water or steam applied to food for brief time | Electric current passed through food to generate heat internally |

| Heating Mechanism | Heat conduction and convection | Internal resistive heating (Joule effect) |

| Starch Gelatinization | Gradual gelatinization due to external heat | Rapid and uniform gelatinization due to volumetric heating |

| Time Efficiency | Longer processing time (minutes) | Shorter processing time (seconds to minutes) |

| Energy Usage | Higher energy consumption | Lower energy consumption, efficient heating |

| Quality Impact | Possible nutrient loss and color degradation | Better retention of nutrients and color |

| Equipment Complexity | Simple, conventional equipment | Advanced equipment requiring electrical control |

| Applications | Common in traditional food processing | Emerging technology for improved food quality |

Introduction to Blanching Techniques in Cooking

Blanching is a traditional cooking technique involving brief exposure of food to boiling water or steam to inactivate enzymes and preserve texture. Ohmic blanching uses electrical currents to heat food internally, offering rapid and uniform heating that enhances starch gelatinization.

- Traditional Blanching - Involves external heat transfer, which may cause uneven temperature distribution and longer processing times.

- Ohmic Blanching - Utilizes electrical resistance heating, resulting in faster and more uniform starch gelatinization within food matrices.

- Impact on Starch Gelatinization - Ohmic blanching improves the efficiency of starch gelatinization, enhancing texture and quality compared to conventional methods.

Overview of Starch Gelatinization

| Blanching typically involves heating starch-containing foods with hot water or steam to initiate gelatinization, causing starch granules to swell and absorb water, which softens the texture. Ohmic blanching uses electrical current passing through the food to generate uniform heat rapidly, promoting more consistent and controlled starch gelatinization. This method enhances starch gelatinization efficiency, reduces processing time, and preserves nutritional and sensory qualities better than conventional blanching. |

Traditional Blanching: Methods and Effects on Starch

Traditional blanching methods, such as hot water and steam blanching, are commonly used to initiate starch gelatinization by applying heat to raw materials. These processes influence the physicochemical properties of starch, affecting texture and digestibility.

- Hot Water Blanching - Involves immersing vegetables in boiling water, causing partial gelatinization and enzyme inactivation.

- Steam Blanching - Uses saturated steam to heat food, preserving nutrients better while inducing starch gelatinization.

- Effect on Starch - Traditional blanching can lead to uneven gelatinization and nutrient loss compared to more advanced techniques.

What is Ohmic Blanching? Principles and Process

Ohmic blanching is a technique that uses electric current to generate heat within food products, leading to rapid and uniform starch gelatinization. The process involves passing alternating electrical current through the food, causing internal heating due to the food's electrical resistance.

This method improves efficiency by reducing blanching time and minimizing nutrient loss compared to traditional blanching. Key principles include electric field application, Joule heating, and controlled temperature regulation to achieve optimal starch gelatinization.

Ohmic Blanching vs Conventional Blanching: Key Differences

Ohmic blanching applies electric current directly through the food, causing rapid and uniform heating that accelerates starch gelatinization compared to conventional blanching, which relies on hot water or steam. This method enhances energy efficiency and minimizes nutrient loss by reducing processing time.

Conventional blanching often results in uneven heat distribution, leading to partial starch gelatinization and potential texture degradation. Ohmic blanching ensures consistent heat treatment, improving product quality and maintaining the structural integrity of starch molecules.

Impact of Blanching Methods on Starch Structure

How do blanching and ohmic blanching affect starch gelatinization differently? Traditional blanching uses hot water or steam, causing uneven heat penetration that may lead to partial gelatinization and altered starch granule structure. Ohmic blanching applies electric current directly through the food, resulting in rapid, uniform heating that enhances starch gelatinization while preserving granular integrity and reducing nutrient loss.

Efficiency and Time Comparison: Blanching vs Ohmic Blanching

Ohmic blanching significantly reduces processing time compared to traditional blanching by directly heating the starch-containing material through electrical resistance. This method leads to more uniform and rapid starch gelatinization, enhancing efficiency and minimizing nutrient loss. Traditional blanching requires longer exposure to heat, resulting in slower gelatinization and higher energy consumption.

Nutrient Retention in Blanching Methods

Conventional blanching causes significant nutrient loss due to prolonged heat exposure and water leaching, impacting vitamin C and phenolic compounds in starchy foods. Ohmic blanching, using electrical currents to generate heat internally, preserves more nutrients by reducing processing time and preventing nutrient diffusion. Studies show ohmic blanching retains up to 30% more ascorbic acid compared to traditional methods during starch gelatinization.

Applications in Food Industry: Choosing the Right Blanching Technique

Blanching and ohmic blanching are critical techniques in the food industry for starch gelatinization during processing. Ohmic blanching offers more uniform heat transfer, enhancing product quality and reducing processing time compared to traditional blanching.

- Thermal Efficiency - Ohmic blanching heats food products internally using electric currents, ensuring rapid and even starch gelatinization.

- Quality Retention - Conventional blanching may cause uneven heating, leading to inconsistent texture and nutrient loss in starchy foods.

- Industrial Application - Ohmic blanching is favored for high-throughput operations requiring precise control over gelatinization and texture uniformity.

Selecting the appropriate blanching method depends on specific food product requirements, processing scale, and desired quality outcomes.

Related Important Terms

Ohmic heating-assisted starch gelatinization

Ohmic heating-assisted starch gelatinization significantly enhances the efficiency of starch gelatinization by providing rapid and uniform heat distribution through electrical current passage, minimizing thermal gradients found in traditional blanching. This method improves starch swelling and molecular disruption at lower processing times and temperatures, preserving nutritional quality and functional properties better than conventional blanching techniques.

Electrothermal blanching

Electrothermal blanching, or ohmic blanching, uses electrical current to generate uniform heat within starchy foods, accelerating starch gelatinization more efficiently than conventional blanching. This method enhances heat penetration and reduces processing time, resulting in improved texture and nutrient retention during starch gelatinization.

Non-thermal pre-gelatinization

Ohmic blanching offers a non-thermal pre-gelatinization method for starch by applying electric current directly through the food matrix, enabling rapid and uniform heat generation that preserves starch granule integrity better than traditional blanching. This technique accelerates starch gelatinization while minimizing nutrient loss and texture degradation, making it a superior process for improving starch functionality in food products.

Rapid resistive heating blanching

Rapid resistive heating blanching, also known as ohmic blanching, accelerates starch gelatinization by applying electric current directly through the food, ensuring uniform heat distribution and minimizing nutrient loss. This method significantly outperforms traditional blanching techniques by reducing processing time and enhancing texture and color retention in starchy foods.

Uniform volumetric starch gelatinization

Ohmic blanching achieves uniform volumetric starch gelatinization by passing electrical current directly through the food, ensuring rapid and consistent heat distribution compared to traditional blanching methods that rely on external heat transfer. This uniform heating minimizes thermal gradients, enhancing starch gelatinization efficiency and preserving product quality.

Instantaneous electric field blanching

Instantaneous electric field blanching, a form of ohmic blanching, induces rapid and uniform starch gelatinization by applying an electric field directly to the food matrix, resulting in faster heat generation and reduced thermal damage compared to conventional blanching. This method enhances starch granule swelling and molecular reorganization more effectively than traditional blanching, improving texture and preserving nutritional quality.

Dielectric-modulated blanching

Dielectric-modulated blanching using ohmic heating enables rapid and uniform starch gelatinization by directly passing electrical current through food, minimizing thermal gradients compared to conventional blanching methods. This approach enhances starch gelatinization efficiency and reduces nutrient loss, optimizing texture and processing time in starch-rich foods.

Pulsed ohmic starch treatment

Pulsed ohmic blanching applies controlled electric pulses to rapidly heat starch-containing materials, enhancing gelatinization efficiency and preserving nutritional quality compared to conventional blanching methods. This technique ensures uniform heat distribution, reducing processing time and minimizing starch degradation while improving texture and functional properties.

Electroporation-aided gelatinization

Ohmic blanching utilizes electroporation to disrupt starch granule membranes, enhancing water penetration and accelerating gelatinization compared to conventional blanching methods. This electroporation-aided gelatinization improves texture uniformity and reduces processing time, resulting in higher-quality starch-based products.

Blanching vs Ohmic Blanching for starch gelatinization. Infographic

cookingdiff.com

cookingdiff.com