Using an ice bowl for blanching pet food helps rapidly cool the product, preserving texture and nutritional value by halting the cooking process immediately. A blast chiller offers more consistent and controlled cooling, reducing bacterial growth and enhancing food safety through precise temperature management. While the ice bowl method is cost-effective and simple, a blast chiller is preferred in commercial settings for its efficiency and ability to maintain product quality at scale.

Table of Comparison

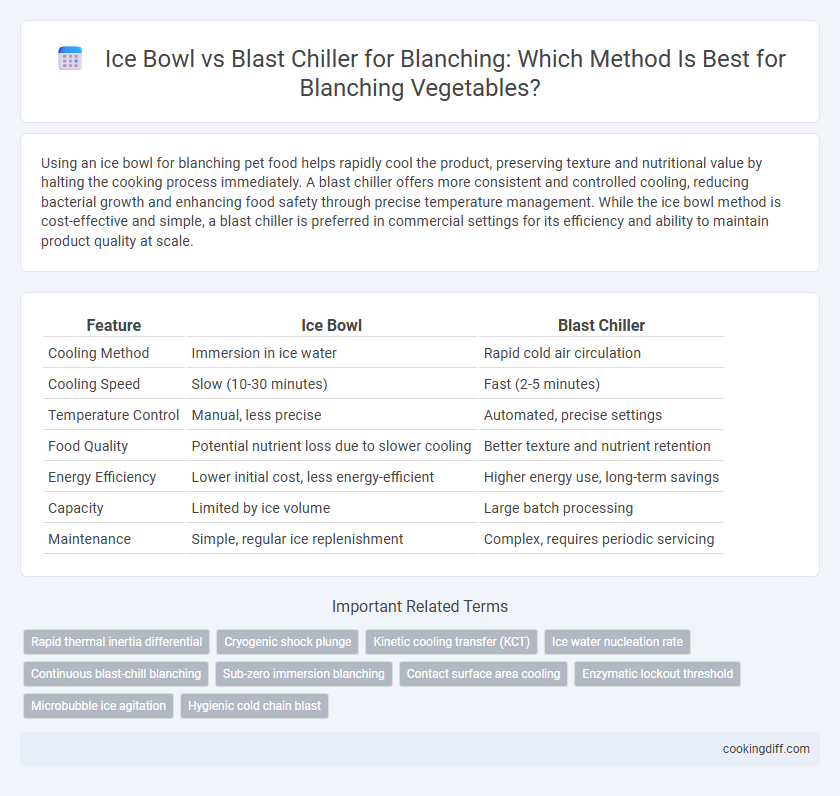

| Feature | Ice Bowl | Blast Chiller |

|---|---|---|

| Cooling Method | Immersion in ice water | Rapid cold air circulation |

| Cooling Speed | Slow (10-30 minutes) | Fast (2-5 minutes) |

| Temperature Control | Manual, less precise | Automated, precise settings |

| Food Quality | Potential nutrient loss due to slower cooling | Better texture and nutrient retention |

| Energy Efficiency | Lower initial cost, less energy-efficient | Higher energy use, long-term savings |

| Capacity | Limited by ice volume | Large batch processing |

| Maintenance | Simple, regular ice replenishment | Complex, requires periodic servicing |

Introduction to Blanching: Ice Bowl vs Blast Chiller

Blanching is a cooking process used to preserve the color, texture, and nutritional value of vegetables by briefly boiling and then rapidly cooling them. An ice bowl cools the vegetables by immersion in cold water mixed with ice, providing a simple and cost-effective method to halt cooking. In contrast, a blast chiller rapidly reduces the temperature using powerful cold airflow, ensuring faster cooling and improved food safety during blanching.

The Science Behind Rapid Cooling in Blanching

Rapid cooling after blanching is crucial to halt enzymatic activity and preserve food texture, color, and nutritional value. Ice bowls use an ice-water mixture to quickly reduce the temperature, creating a conductive cooling effect, while blast chillers employ powerful cold air circulation for faster heat removal through convection. Blast chillers offer more precise temperature control and uniform cooling, reducing the risk of microbial growth and extending shelf life compared to traditional ice bowl methods.

How Ice Bowls Work for Blanching

Ice bowls for blanching use crushed ice and water to rapidly cool vegetables immediately after boiling, preserving texture and nutritional value. This method relies on the consistent cold temperature of the ice bath to halt the cooking process efficiently.

- Temperature control - The ice bowl maintains a steady 0degC environment essential for stopping heat transfer and enzymatic activity quickly.

- Simple setup - Unlike blast chillers, ice bowls require minimal equipment and are easy to assemble for small to medium-scale blanching operations.

- Cost-effective - Ice bowls offer a low-cost cooling alternative without the high energy consumption associated with blast chillers.

Blast Chillers: Modern Solution for Blanching

Blast chillers offer a rapid cooling process that preserves the texture and nutritional value of blanched vegetables better than traditional ice bowls. Their advanced technology ensures food safety by minimizing bacterial growth during temperature reduction.

- Efficient Cooling - Blast chillers can reduce the temperature of blanched food from 70degC to 3degC in under 90 minutes, much faster than ice bowls.

- Enhanced Food Quality - By cooling quickly, blast chillers maintain crispness and color of vegetables without waterlogging or nutrient loss.

- Food Safety Compliance - Rapid chilling significantly limits bacterial proliferation ensuring compliance with HACCP standards.

Key Differences: Ice Bowl vs Blast Chiller

| Feature | Ice Bowl | Blast Chiller |

|---|---|---|

| Cooling Method | Immersion in ice water to rapidly stop cooking | Forced air circulation at ultra-low temperatures for quick chilling |

| Temperature Control | Relies on ice water temperature, typically around 0degC | Precise temperature regulation, often reaching -40degC |

| Cooling Speed | Moderate cooling speed dependent on ice quality and water circulation | Rapid cooling within minutes, reducing microbial growth risk |

| Food Quality Impact | Maintains texture but can cause water absorption | Preserves texture and color without moisture increase |

Pros and Cons of Using an Ice Bowl

Using an ice bowl for blanching offers a straightforward and cost-effective method to quickly cool vegetables and halt the cooking process. However, it may be less efficient in temperature control and slower compared to a blast chiller.

- Cost-Effective - Ice bowls require minimal investment and use readily available ice, making them economical for small-scale operations.

- Temperature Control Limits - Maintaining a consistent low temperature can be challenging, potentially impacting the quality of blanching.

- Slower Cooling Speed - Ice bowls cool produce at a slower rate compared to blast chillers, which may affect texture and freshness.

Ice bowls are suitable for low-volume blanching but may not meet the efficiency demands of commercial food processing.

Advantages and Disadvantages of Blast Chillers

Blast chillers rapidly reduce the temperature of blanched vegetables, preserving texture, color, and nutritional value more effectively than ice bowl methods. They minimize microbial growth by quickly lowering food temperature within the critical safety zone.

Blast chillers require significantly higher initial investment and consume more energy compared to traditional ice bowl cooling. Maintenance can be complex due to mechanical parts, potentially increasing operational costs. However, their efficiency in reducing food spoilage and extending shelf life often outweighs these disadvantages for commercial operations.

Impact on Food Quality: Ice Bowl vs Blast Chiller

Ice bowls rapidly cool blanched vegetables by immersing them in cold water, which may cause slight nutrient loss and texture softening due to water absorption. In contrast, blast chillers reduce temperature quickly through cold air circulation, preserving more nutrients and maintaining firmer texture.

Blast chillers minimize enzymatic activity and microbial growth more effectively than ice bowls, ensuring superior food safety and longer shelf life. Ice bowls are simpler but can lead to waterborne contamination and less consistent cooling results, impacting overall food quality.

Cost, Space, and Accessibility Considerations

Which method is more cost-effective for blanching: ice bowl or blast chiller? Ice bowls typically have lower upfront costs but require more manual handling and frequent water replacement, increasing labor expenses. Blast chillers involve higher initial investment but save space and provide consistent temperature control, improving operational efficiency.

Related Important Terms

Rapid thermal inertia differential

Ice bowls absorb heat gradually during blanching, resulting in slower thermal inertia reduction, while blast chillers rapidly lower food temperature through intense cold air circulation, creating a significant differential in thermal inertia that enhances process efficiency and food quality preservation. Rapid thermal inertia reduction with blast chillers minimizes residual heat and enzymatic activity, optimizing texture and color retention compared to the slower cooling effect of ice bowls.

Cryogenic shock plunge

Ice bowl blanching uses cold water immersion to rapidly cool vegetables but may cause uneven temperature reduction and enzymatic activity. Blast chillers employing cryogenic shock plunge with liquid nitrogen or carbon dioxide achieve ultra-rapid cooling, preserving texture and nutrients more effectively by instantly halting enzymatic degradation.

Kinetic cooling transfer (KCT)

Ice bowls provide a slower Kinetic Cooling Transfer (KCT) due to the limited surface contact and lower cooling rate, which may result in less efficient enzyme inactivation during blanching. Blast chillers maximize KCT by rapidly lowering product temperature through forced cold air circulation, ensuring faster heat removal and improved retention of color and texture in blanched vegetables.

Ice water nucleation rate

Ice bowl chilling offers a slower nucleation rate due to its higher heat capacity and gradual temperature reduction, which can result in uneven enzyme inactivation during blanching. Blast chillers achieve a rapid nucleation rate by quickly reducing the temperature, promoting faster enzyme deactivation and improved texture retention in blanched vegetables.

Continuous blast-chill blanching

Continuous blast-chill blanching offers superior temperature control and consistent heat removal compared to traditional ice bowl methods, enhancing product quality and reducing microbial load effectively. This method integrates rapid cooling immediately after blanching, minimizing thermal stress and preserving texture, color, and nutritional value in vegetables.

Sub-zero immersion blanching

Ice bowl immersion blanching rapidly reduces vegetable temperature below 0degC, preserving texture and nutrient content by halting enzymatic activity swiftly; blast chillers, while effective at rapid cooling, typically operate above freezing, making them less optimal for true sub-zero immersion blanching. Sub-zero immersion in ice bowls ensures superior retention of color, crispness, and vitamin levels compared to blast chilling, which primarily targets rapid cooling without reaching sub-zero temperatures necessary for maximal enzymatic inhibition.

Contact surface area cooling

Ice bowls provide a large contact surface area that ensures consistent and rapid cooling during blanching, reducing thermal shock and preserving texture better. Blast chillers, while efficient, rely on airflow which offers less direct contact and slower heat transfer compared to the extensive surface interaction in ice bowl cooling.

Enzymatic lockout threshold

Ice bowls maintain blanching temperatures just above the enzymatic lockout threshold, ensuring enzyme activity is halted without overcooking, while blast chillers rapidly reduce temperatures below this critical point to prevent residual enzymatic reactions and preserve food quality. Choosing between the two depends on the precision required in controlling enzymatic inactivation during blanching processes.

Microbubble ice agitation

Ice bowl blanching with microbubble ice agitation enhances heat transfer efficiency by creating uniform cooling around vegetables, minimizing texture degradation and nutrient loss. Blast chillers provide rapid temperature reduction but lack the microbubble agitation that promotes better surface contact and faster cooling in ice bowl systems.

Ice bowl vs Blast chiller for blanching Infographic

cookingdiff.com

cookingdiff.com