Blanching effectively inactivates enzymes such as polyphenol oxidase and peroxidase, which are responsible for browning and color degradation in fruits and vegetables. Enzyme inactivation through blanching preserves the vibrant color by halting oxidative reactions that lead to discoloration. This thermal treatment ensures longer shelf life and maintains visual appeal in fresh produce.

Table of Comparison

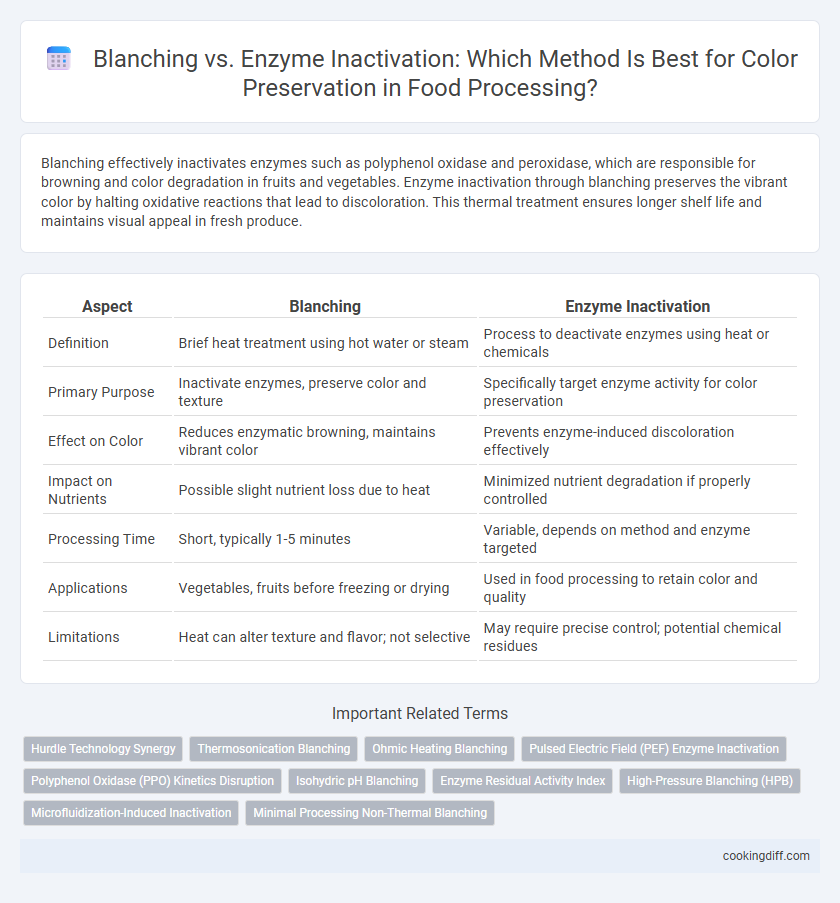

| Aspect | Blanching | Enzyme Inactivation |

|---|---|---|

| Definition | Brief heat treatment using hot water or steam | Process to deactivate enzymes using heat or chemicals |

| Primary Purpose | Inactivate enzymes, preserve color and texture | Specifically target enzyme activity for color preservation |

| Effect on Color | Reduces enzymatic browning, maintains vibrant color | Prevents enzyme-induced discoloration effectively |

| Impact on Nutrients | Possible slight nutrient loss due to heat | Minimized nutrient degradation if properly controlled |

| Processing Time | Short, typically 1-5 minutes | Variable, depends on method and enzyme targeted |

| Applications | Vegetables, fruits before freezing or drying | Used in food processing to retain color and quality |

| Limitations | Heat can alter texture and flavor; not selective | May require precise control; potential chemical residues |

Understanding Blanching: Definition and Purpose

Blanching is a thermal process that involves briefly heating vegetables or fruits to inactivate enzymes responsible for color degradation. Enzyme inactivation during blanching prevents oxidation and browning reactions, thus preserving the natural color and extending shelf life. Compared to other enzyme inactivation methods, blanching is cost-effective and widely used in the food processing industry for maintaining vibrant appearance in fresh produce.

The Science Behind Enzyme Inactivation

Blanching inactivates enzymes by exposing vegetables to high temperatures briefly, disrupting enzyme structure responsible for oxidation and color degradation. Enzyme inactivation primarily targets polyphenol oxidase, which catalyzes browning reactions affecting visual quality.

The science behind enzyme inactivation involves denaturation of these proteins through thermal shock, preventing enzymatic activity that leads to pigment breakdown. Precise temperature and time control during blanching preserves vibrant color by halting chlorophyll and carotenoid degradation pathways.

Color Preservation in Food: Why It Matters

Blanching rapidly heats food to inactivate enzymes responsible for browning, effectively preserving the vibrant color of fruits and vegetables. Enzyme inactivation through blanching is critical in maintaining visual appeal, which directly impacts consumer acceptance and market value.

Color preservation is vital in food processing as it signals freshness and quality to consumers, influencing purchasing decisions. Blanching targets enzymes like polyphenol oxidase, preventing undesirable color changes that occur during storage and cooking. Compared to other methods, blanching provides a balance between enzyme inactivation and minimal nutrient loss, making it a preferred technique in the food industry.

Blanching Techniques for Optimal Color Retention

Blanching techniques such as steam blanching and hot water blanching are critical for optimal enzyme inactivation to preserve the vibrant color of vegetables. Precise control of blanching time and temperature minimizes enzymatic browning and pigment degradation, ensuring better color retention. Industrial applications favor rapid blanching methods to retain chlorophyll and carotenoids, enhancing product appeal and nutritional quality.

Enzyme Inactivation Methods Explained

Enzyme inactivation methods are critical for preserving color in fruits and vegetables by halting enzymatic reactions that cause browning and degradation. Techniques such as thermal blanching, high-pressure processing, and pulsed electric fields effectively disrupt enzyme activity to maintain visual quality.

- Thermal Blanching - Uses heat to denature enzymes, preventing discoloration during storage and processing.

- High-Pressure Processing - Applies intense pressure to inactivate enzymes without significant heat, preserving color and nutrients.

- Pulsed Electric Fields - Employs short bursts of electricity to deactivate enzymes rapidly, enhancing color stability in fresh produce.

Comparing Efficacy: Blanching vs Enzyme Inactivation

Blanching effectively reduces enzymatic activity by exposing vegetables to high temperatures for short durations, thereby preserving color and texture in produce such as green beans and spinach. Enzyme inactivation through blanching specifically targets polyphenol oxidase and peroxidase enzymes, which are primarily responsible for color degradation.

Enzyme inactivation techniques like chemical inhibitors or controlled atmosphere storage offer alternative methods but often lack the immediate efficacy of thermal blanching in halting enzymatic browning. Comparing both, blanching provides more consistent and rapid enzyme deactivation, making it a preferred choice in industrial food processing for color preservation.

Temperature and Timing: Key Factors in Color Preservation

| Process | Temperature Range | Timing | Effect on Color Preservation |

|---|---|---|---|

| Blanching | 70degC to 100degC | 30 seconds to 5 minutes | Rapid heating deactivates enzymes, preventing oxidation and maintaining vibrant color. |

| Enzyme Inactivation | Varies depending on enzyme (e.g., PPO inactivation at ~80degC) | Typically shorter, precise timing to avoid overcooking | Targeted enzyme inactivation preserves pigment integrity and minimizes color degradation. |

Pros and Cons: Blanching Versus Enzyme Inactivation

Blanching rapidly heats vegetables to inactivate enzymes responsible for color degradation, offering effective color preservation but sometimes causing nutrient loss. Enzyme inactivation methods like chemical inhibitors maintain color with minimal thermal damage but may introduce residues or alter taste.

- Blanching Efficiency - Quickly denatures enzymes like polyphenol oxidase, effectively preserving color in many vegetables.

- Thermal Impact - High temperatures during blanching can degrade heat-sensitive nutrients and affect texture.

- Chemical Enzyme Inactivation - Uses inhibitors to directly block enzymatic activity without heat, reducing nutrient loss but raising safety concerns.

Choosing between blanching and enzyme inactivation depends on balancing color retention, nutrient preservation, and processing safety.

Common Mistakes in Color Preservation Processes

How do common mistakes in blanching affect enzyme inactivation for color preservation? Improper blanching times and temperatures often fail to fully inactivate polyphenol oxidase, leading to enzymatic browning and color degradation. Overheating can cause pigment leaching, while insufficient heat allows enzymes to remain active, compromising the visual quality of fruits and vegetables.

Related Important Terms

Hurdle Technology Synergy

Blanching rapidly inactivates polyphenol oxidase enzymes responsible for color degradation, while enzyme inactivation methods target broader enzymatic activities, enhancing color retention in produce. Combining blanching with enzyme inactivation creates a hurdle technology synergy that effectively preserves color by simultaneously disrupting enzymatic pathways and cellular structures.

Thermosonication Blanching

Thermosonication blanching combines ultrasonic waves with controlled thermal treatment to enhance enzyme inactivation, significantly preserving the natural color of fruits and vegetables compared to conventional blanching methods. This technique reduces nutrient loss and color degradation by effectively targeting polyphenol oxidase and peroxidase enzymes responsible for discoloration.

Ohmic Heating Blanching

Ohmic heating blanching effectively inactivates enzymes such as polyphenol oxidase and peroxidase, preserving the color of fruits and vegetables by minimizing enzymatic browning. This method provides rapid, uniform heating that outperforms conventional blanching in maintaining product quality and color stability during storage.

Pulsed Electric Field (PEF) Enzyme Inactivation

Pulsed Electric Field (PEF) enzyme inactivation preserves color more effectively than traditional blanching by minimizing thermal damage and maintaining cell structure integrity. This non-thermal technique reduces enzymatic browning while retaining nutrients and fresh-like appearance in fruits and vegetables.

Polyphenol Oxidase (PPO) Kinetics Disruption

Blanching effectively disrupts Polyphenol Oxidase (PPO) kinetics by denaturing the enzyme responsible for browning, thereby preserving the natural color of fruits and vegetables. In contrast, enzyme inactivation methods that do not involve heat may fail to fully inhibit PPO activity, resulting in incomplete color preservation.

Isohydric pH Blanching

Isohydric pH blanching optimizes color preservation by maintaining a stable pH environment that effectively inactivates polyphenol oxidase enzymes responsible for browning. This method surpasses conventional blanching by preserving chlorophyll and carotenoid pigments, resulting in brighter, more vibrant food products.

Enzyme Residual Activity Index

Blanching significantly reduces the Enzyme Residual Activity Index (ERAI), effectively inactivating polyphenol oxidase and peroxidase enzymes responsible for color degradation in fruits and vegetables. Maintaining a low ERAI through optimized blanching parameters ensures superior color preservation by preventing enzymatic browning and oxidative reactions.

High-Pressure Blanching (HPB)

High-Pressure Blanching (HPB) offers superior enzyme inactivation compared to traditional blanching methods, effectively preserving the vibrant color of fruits and vegetables by minimizing pigment degradation. This non-thermal technique maintains cellular integrity and enhances color retention by selectively targeting peroxidase and polyphenol oxidase enzymes responsible for enzymatic browning.

Microfluidization-Induced Inactivation

Microfluidization-induced inactivation offers a more uniform and effective enzyme deactivation compared to traditional blanching, resulting in superior color preservation in fruits and vegetables. This advanced technique utilizes high-pressure microfluidic forces to disrupt enzyme structures, minimizing color degradation and enhancing product quality.

Blanching vs Enzyme Inactivation for color preservation. Infographic

cookingdiff.com

cookingdiff.com