Blanching effectively preserves food texture by inactivating enzymes that cause deterioration, but it often results in some softening due to heat exposure. High-pressure blanching offers superior texture control by applying intense pressure at lower temperatures, maintaining firmness and crispness more effectively. This method reduces the loss of nutrients and sensory qualities, making it a preferred choice for preserving the original texture of delicate produce.

Table of Comparison

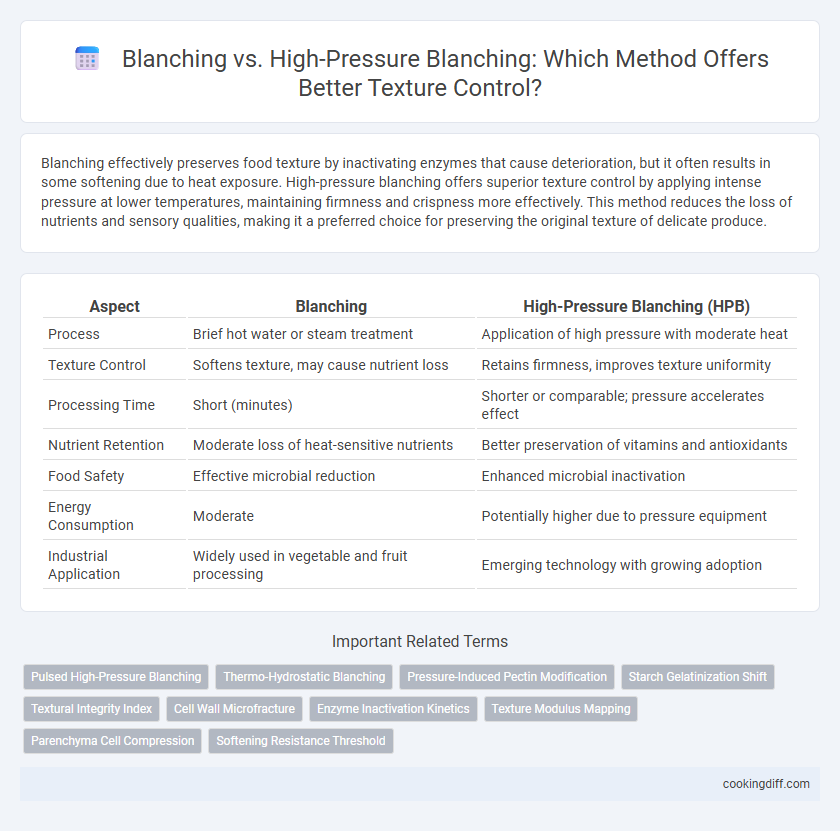

| Aspect | Blanching | High-Pressure Blanching (HPB) |

|---|---|---|

| Process | Brief hot water or steam treatment | Application of high pressure with moderate heat |

| Texture Control | Softens texture, may cause nutrient loss | Retains firmness, improves texture uniformity |

| Processing Time | Short (minutes) | Shorter or comparable; pressure accelerates effect |

| Nutrient Retention | Moderate loss of heat-sensitive nutrients | Better preservation of vitamins and antioxidants |

| Food Safety | Effective microbial reduction | Enhanced microbial inactivation |

| Energy Consumption | Moderate | Potentially higher due to pressure equipment |

| Industrial Application | Widely used in vegetable and fruit processing | Emerging technology with growing adoption |

Introduction to Blanching Techniques

Blanching is a traditional thermal process used to inactivate enzymes and preserve texture in fruits and vegetables. High-pressure blanching employs elevated pressure levels to achieve similar enzyme inactivation while better maintaining structural integrity and crispness. This technique reduces cooking time and nutrient loss compared to conventional blanching methods.

What is Traditional Blanching?

| Traditional blanching is a heat treatment process where vegetables or fruits are briefly immersed in boiling water or exposed to steam to inactivate enzymes that cause spoilage. This method softens the texture by partially cooking the produce, which helps in preserving color and flavor during subsequent freezing or drying. However, it may lead to nutrient loss and texture changes due to the high temperature and water exposure. |

Understanding High-Pressure Blanching

High-pressure blanching (HPB) utilizes elevated pressure levels up to 600 MPa to inactivate enzymes without significant heat application, preserving the texture of vegetables better than conventional blanching. This method reduces cellular damage and maintains firmness by minimizing thermal stress, which is critical for texture control in food processing.

Compared to traditional blanching that relies on hot water or steam, HPB enhances retention of nutrients and color due to shorter processing times and lower temperature exposure. Research shows that high-pressure blanching can achieve similar enzyme inactivation while maintaining crispness, making it a superior technique for texture-sensitive foods.

The Science Behind Texture Control

Blanching uses heat to deactivate enzymes affecting texture, causing cell wall softening and pectin breakdown. High-pressure blanching applies intense pressure to preserve cell structure, resulting in crisper textures and reduced nutrient loss.

- Heat-Induced Cell Softening - Thermal blanching disrupts cell membranes and solubilizes pectin, leading to softer textures.

- Pressure Preservation of Cell Integrity - High-pressure blanching maintains cell wall rigidity by minimizing thermal damage.

- Enzymatic Activity Control - Both methods reduce enzymatic browning, but high-pressure blanching offers superior retention of texture-related enzymes.

Key Differences: Standard vs High-Pressure Blanching

Standard blanching involves exposing vegetables to boiling water or steam for a short duration to inactivate enzymes and preserve color and texture. High-pressure blanching uses elevated pressure combined with moderate temperatures, enhancing texture retention and reducing nutrient loss compared to traditional methods.

Key differences include improved firmness and reduced overcooking in high-pressure blanching, which better maintains cell structure. This technique also shortens processing time and enhances shelf life, offering superior texture control over standard blanching.

Texture Outcomes: Side-by-Side Comparison

Blanching traditionally uses hot water or steam to inactivate enzymes and soften textures, often resulting in slight nutrient loss and softer produce surfaces. High-pressure blanching employs elevated pressure and moderate temperature to preserve cellular structure and firmness, leading to crisper textures and better retention of color and nutrients. Studies show high-pressure blanching enhances texture control by minimizing tissue damage compared to conventional blanching methods.

Nutrient Retention in Both Methods

Blanching and high-pressure blanching differ significantly in nutrient retention, with high-pressure blanching preserving a higher amount of vitamins and minerals due to reduced thermal exposure. This method maintains the texture of vegetables more effectively while enhancing nutrient bioavailability compared to conventional blanching techniques.

- Vitamin retention - High-pressure blanching minimizes vitamin loss, particularly vitamin C and B-complex vitamins, by using lower temperatures and shorter processing times.

- Mineral preservation - Both methods retain essential minerals like potassium and magnesium, but high-pressure blanching shows reduced leaching into water, enhancing nutrient retention.

- Texture and nutrient synergy - High-pressure blanching maintains cell integrity, which helps preserve both nutrient content and desirable texture in processed vegetables.

Applications in Culinary Practices

Blanching is widely used in culinary practices to soften vegetables and maintain vibrant color by briefly immersing them in boiling water or steam. High-pressure blanching, utilizing pressures up to 600 MPa, offers superior texture control by preserving cell integrity and reducing nutrient loss compared to conventional methods.

In applications such as vegetable preservation and preparation for freezing, high-pressure blanching enhances crispness and firmness, making it ideal for premium fresh-cut produce. This technique minimizes enzymatic activity while retaining sensory qualities, which is crucial for gourmet dishes requiring precise texture. Chefs favor high-pressure blanching for maintaining the natural bite of ingredients in salads, stir-fries, and blanched vegetable platters.

Pros and Cons: Texture, Color, and Flavor

How do blanching and high-pressure blanching compare in texture control for vegetables? Traditional blanching softens vegetables but can lead to nutrient loss and color fading, while high-pressure blanching better preserves crispness and vibrant color by minimizing heat exposure. However, high-pressure blanching requires specialized equipment and can alter flavor profiles due to pressure effects on cellular structures.

Related Important Terms

Pulsed High-Pressure Blanching

Pulsed High-Pressure Blanching (PHPB) enhances texture control by applying cyclic pressure variations that preserve cellular integrity better than conventional blanching, resulting in firmer and crisper produce. This method reduces cooking time and nutrient loss while maintaining superior texture quality compared to traditional thermal blanching techniques.

Thermo-Hydrostatic Blanching

Thermo-hydrostatic blanching utilizes high-pressure steam to rapidly stabilize texture by minimizing moisture loss and enzymatic activity compared to conventional blanching methods. This process preserves cell structure and firmness more effectively, resulting in enhanced product quality and prolonged shelf life.

Pressure-Induced Pectin Modification

Blanching modifies vegetable texture primarily by inactivating enzymes, but high-pressure blanching leverages Pressure-Induced Pectin Modification to maintain firmer cell structures and improve crispness. This technique alters pectin molecules within the cell wall, enhancing texture retention more effectively than conventional thermal blanching methods.

Starch Gelatinization Shift

High-pressure blanching shifts starch gelatinization to higher temperatures compared to traditional blanching, preserving the firmness and texture of vegetables more effectively. This method reduces the softening typically caused by heat, resulting in improved texture control during processing.

Textural Integrity Index

Blanching techniques impact the Textural Integrity Index by altering cell structure and firmness, with traditional blanching often causing more significant texture degradation due to heat exposure. High-Pressure Blanching preserves the Textural Integrity Index more effectively by applying pressure that maintains cell turgor and firmness, resulting in superior texture retention in processed foods.

Cell Wall Microfracture

Blanching induces controlled cell wall microfracture, which softens vegetable texture by disrupting pectin structures, whereas high-pressure blanching generates more uniform and precise microfractures, preserving cell integrity and resulting in firmer texture retention. The enhanced cell wall modifications under high-pressure blanching optimize texture control by balancing firmness and tenderness through targeted microstructural changes.

Enzyme Inactivation Kinetics

Blanching inactivates enzymes through heat-induced denaturation following first-order kinetics, typically requiring exposure at 70-100degC for 1-5 minutes to achieve effective texture preservation. High-pressure blanching accelerates enzyme inactivation by applying pressures of 300-600 MPa combined with moderate temperatures, disrupting enzyme structures more efficiently and maintaining a firmer texture compared to conventional thermal blanching.

Texture Modulus Mapping

Blanching traditionally softens vegetable tissues through heat-induced enzyme inactivation, often resulting in uneven texture profiles measurable by Texture Modulus Mapping, which reveals localized firmness variations. High-Pressure Blanching (HPB) enhances texture uniformity by applying isostatic pressure combined with mild heat, producing more consistent Texture Modulus Mapping results that indicate improved cell wall integrity and reduced tissue degradation.

Parenchyma Cell Compression

Blanching causes parenchyma cell compression through heat-induced cell wall softening, resulting in texture softening and potential nutrient loss, while high-pressure blanching applies uniform pressure that preserves cell integrity and maintains firmer texture by minimizing cell collapse. Studies show high-pressure blanching better retains the turgidity and structure of parenchyma cells, enhancing the crispness and overall quality of fruits and vegetables.

Blanching vs High-Pressure Blanching for texture control. Infographic

cookingdiff.com

cookingdiff.com