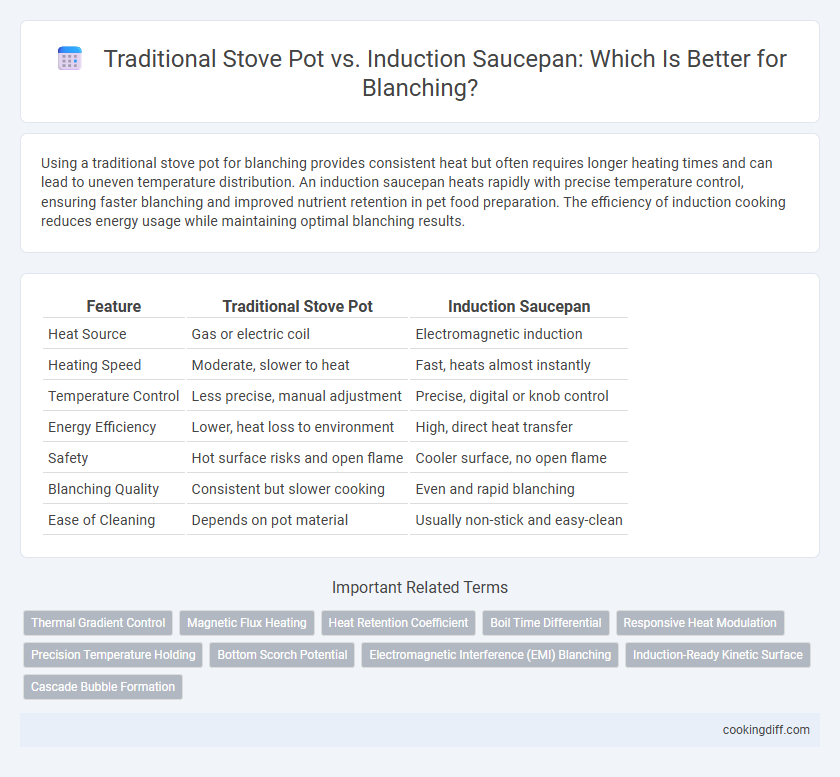

Using a traditional stove pot for blanching provides consistent heat but often requires longer heating times and can lead to uneven temperature distribution. An induction saucepan heats rapidly with precise temperature control, ensuring faster blanching and improved nutrient retention in pet food preparation. The efficiency of induction cooking reduces energy usage while maintaining optimal blanching results.

Table of Comparison

| Feature | Traditional Stove Pot | Induction Saucepan |

|---|---|---|

| Heat Source | Gas or electric coil | Electromagnetic induction |

| Heating Speed | Moderate, slower to heat | Fast, heats almost instantly |

| Temperature Control | Less precise, manual adjustment | Precise, digital or knob control |

| Energy Efficiency | Lower, heat loss to environment | High, direct heat transfer |

| Safety | Hot surface risks and open flame | Cooler surface, no open flame |

| Blanching Quality | Consistent but slower cooking | Even and rapid blanching |

| Ease of Cleaning | Depends on pot material | Usually non-stick and easy-clean |

Introduction to Blanching: Basics and Benefits

| Traditional stove pots rely on direct flame, resulting in variable heat distribution that can affect blanching consistency. Induction saucepans use electromagnetic fields for rapid, even heating, ensuring precise temperature control during blanching. Efficient heat management in induction cooking enhances nutrient retention and texture preservation in vegetables. |

Overview: Traditional Stove Pot vs Induction Saucepan

Traditional stove pots rely on gas or electric heat sources, resulting in slower and less consistent temperature control compared to induction saucepans, which use electromagnetic fields for rapid and precise heating. Induction saucepans offer improved energy efficiency and faster blanching times, enhancing cooking accuracy and vegetable texture.

- Heat transfer efficiency - Induction saucepans provide faster, more even heating than traditional stove pots.

- Temperature control - Induction allows precise temperature adjustments for consistent blanching results.

- Energy consumption - Induction uses less energy by directly heating the pan, reducing heat loss.

Heat Distribution and Temperature Control

Traditional stove pots often exhibit uneven heat distribution, resulting in inconsistent blanching and potential overcooking of food edges. Induction saucepans provide rapid and uniform heat transfer due to electromagnetic heating directly targeting the pan base.

Temperature control is less precise with traditional stove pots, relying on fluctuating gas or electric burner outputs that can cause temperature spikes. Induction saucepans offer accurate and instant temperature adjustments, ensuring optimal blanching conditions and nutrient retention.

Energy Efficiency in Blanching Methods

Induction saucepans heat food directly through electromagnetic energy, resulting in higher energy efficiency during blanching compared to traditional stove pots that rely on indirect heat conduction. This direct heating mechanism reduces energy waste and shortens cooking time, making induction a more sustainable choice for blanching vegetables.

- Lower Energy Consumption - Induction saucepans consume up to 90% of energy efficiently, while traditional stoves average around 40%-55% efficiency.

- Faster Heat-Up Time - Induction reaches blanching temperatures rapidly, reducing overall energy use and preserving nutrient quality in vegetables.

- Reduced Heat Loss - Minimal heat escapes into the environment with induction, unlike traditional stoves that lose significant heat to surrounding air.

Speed and Convenience: Which is Faster?

Induction saucepans heat up significantly faster than traditional stove pots due to electromagnetic energy directly warming the cookware. This rapid heat transfer reduces blanching time and improves energy efficiency, making induction cooking more convenient for quick tasks. Traditional stove pots, relying on gas or electric burners, typically take longer to reach the desired temperature, slowing down the blanching process.

Water Boiling Time Comparison

Induction saucepans significantly reduce water boiling time compared to traditional stove pots during blanching, enhancing overall kitchen efficiency. The rapid electromagnetic heating of induction cooktops leads to faster temperature rise and more precise control.

- Induction saucepan water boiling time - Typically 30-50% faster than traditional stove pots.

- Traditional stove pot efficiency - Slower heat transfer due to gas or electric coil heating methods.

- Energy consumption - Induction reduces energy use by focusing heat directly on the pan bottom.

Faster water boiling in induction saucepans results in quicker blanching and improved nutrient retention in vegetables.

Safety Features for Home Cooks

Traditional stove pots can pose higher safety risks for home cooks due to open flames and uneven heat distribution, increasing the likelihood of burns and accidental fires. Induction saucepans, with their precise temperature control and cool-to-touch surfaces, minimize these hazards and provide safer cooking conditions.

Induction cooktops automatically shut off when no pan is detected, reducing the risk of unattended heating and potential kitchen accidents. This built-in safety feature is absent in traditional stoves, making induction saucepans a safer choice for blanching in home kitchens.

Flavor and Color Preservation

Blanching vegetables in a traditional stove pot often leads to uneven heating, which can cause slight flavor loss and duller colors due to prolonged exposure to heat. Induction saucepans provide precise temperature control, preserving the vibrant color and fresh flavor by rapidly reaching and maintaining the ideal blanching temperature. This efficient heat distribution minimizes nutrient loss and enhances the overall quality of blanched produce.

Equipment Maintenance and Longevity

Traditional stove pots often require frequent cleaning due to uneven heat distribution causing food residue buildup, which can degrade the pot's surface over time. Induction saucepans, designed with magnetic bases, offer more consistent heating and typically feature non-stick surfaces that simplify maintenance and reduce wear.

The durable construction of induction saucepans, usually stainless steel or hard-anodized aluminum, extends their longevity compared to traditional pots prone to warping and discoloration from open flames. Regular cleaning and avoidance of abrasive materials ensure both types maintain performance, though induction cookware tends to resist scratches and stains better. Optimal use on induction cooktops minimizes energy waste, further preserving the equipment's condition during repetitive blanching tasks.

Related Important Terms

Thermal Gradient Control

Induction saucepans offer precise thermal gradient control during blanching by allowing rapid and uniform heat distribution, minimizing temperature fluctuations that can affect vegetable texture and color. Traditional stove pots often create uneven heating zones, leading to inconsistent blanching results and potential nutrient loss.

Magnetic Flux Heating

Magnetic flux heating in induction saucepans offers rapid, uniform heat distribution essential for precise blanching, reducing cooking time and nutrient loss compared to traditional stove pots that rely on slower, uneven thermal conduction. Induction technology's electromagnetic fields generate heat directly in the cookware, enhancing temperature control and energy efficiency during the blanching process.

Heat Retention Coefficient

Traditional stove pots generally have a higher heat retention coefficient due to their thicker metal construction, allowing for more stable temperature maintenance during blanching. In contrast, induction saucepans heat rapidly but may lose heat faster once removed from the induction source, impacting consistent blanching quality.

Boil Time Differential

Induction saucepans significantly reduce boil time compared to traditional stove pots due to their rapid and uniform heat distribution, allowing water to reach boiling point nearly twice as fast. This efficiency not only speeds up the blanching process but also enhances energy savings and temperature control precision.

Responsive Heat Modulation

Induction saucepans offer precise and rapid responsive heat modulation compared to traditional stove pots, enabling consistent blanching temperatures critical for preserving vegetable texture and color. This efficient heat control minimizes cooking time and nutrient loss, enhancing overall blanching quality and energy use.

Precision Temperature Holding

Induction saucepans offer precise temperature control during blanching, maintaining consistent heat levels to prevent overcooking or undercooking. Traditional stove pots often experience temperature fluctuations, making it harder to achieve optimal blanching results.

Bottom Scorch Potential

Traditional stove pots often have uneven heat distribution, increasing bottom scorch potential during blanching and risking nutrient loss or burning. Induction saucepans provide precise temperature control and even heat distribution, significantly reducing the risk of bottom scorching and ensuring consistent blanching results.

Electromagnetic Interference (EMI) Blanching

Induction saucepans generate electromagnetic interference (EMI) due to their reliance on magnetic fields, which can disrupt nearby electronic devices during blanching, unlike traditional stove pots that produce minimal EMI. Optimizing blanching with induction technology requires considering EMI mitigation strategies to ensure safe kitchen environments without compromising cooking efficiency.

Induction-Ready Kinetic Surface

Induction-ready kinetic surfaces enhance blanching efficiency by providing rapid, uniform heat distribution compared to traditional stove pots, reducing cooking times and preserving vegetable texture and nutrients. The precise temperature control of induction saucepans minimizes nutrient loss and prevents overcooking, making them ideal for consistent blanching results.

Traditional stove pot vs induction saucepan for blanching. Infographic

cookingdiff.com

cookingdiff.com