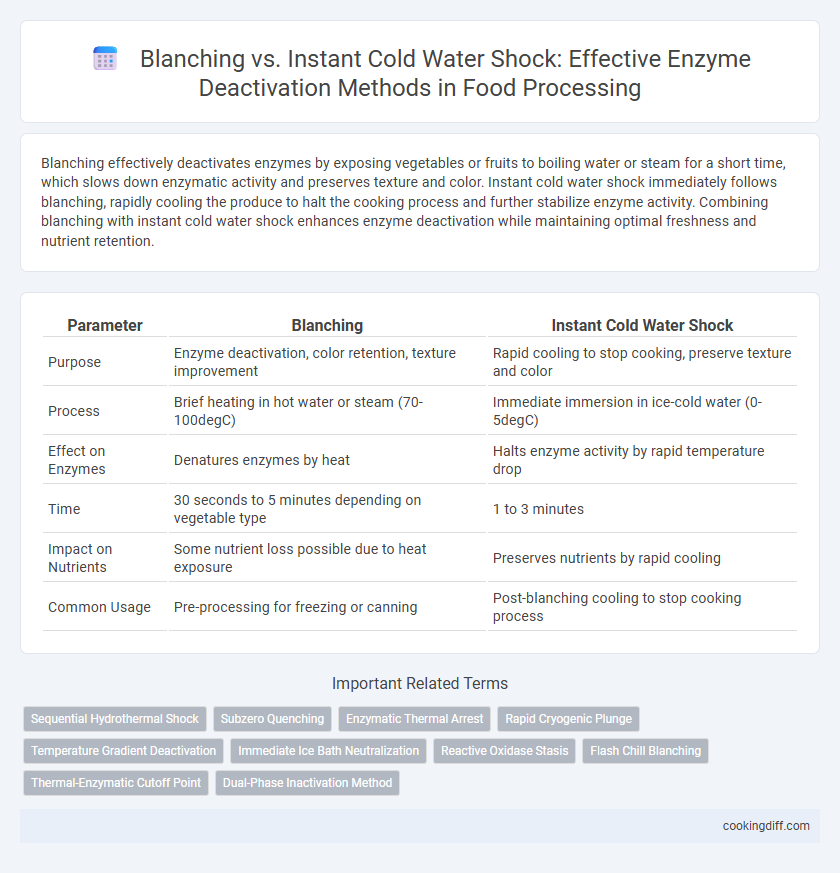

Blanching effectively deactivates enzymes by exposing vegetables or fruits to boiling water or steam for a short time, which slows down enzymatic activity and preserves texture and color. Instant cold water shock immediately follows blanching, rapidly cooling the produce to halt the cooking process and further stabilize enzyme activity. Combining blanching with instant cold water shock enhances enzyme deactivation while maintaining optimal freshness and nutrient retention.

Table of Comparison

| Parameter | Blanching | Instant Cold Water Shock |

|---|---|---|

| Purpose | Enzyme deactivation, color retention, texture improvement | Rapid cooling to stop cooking, preserve texture and color |

| Process | Brief heating in hot water or steam (70-100degC) | Immediate immersion in ice-cold water (0-5degC) |

| Effect on Enzymes | Denatures enzymes by heat | Halts enzyme activity by rapid temperature drop |

| Time | 30 seconds to 5 minutes depending on vegetable type | 1 to 3 minutes |

| Impact on Nutrients | Some nutrient loss possible due to heat exposure | Preserves nutrients by rapid cooling |

| Common Usage | Pre-processing for freezing or canning | Post-blanching cooling to stop cooking process |

Understanding Blanching: The Science Behind Heat Treatment

Blanching involves briefly exposing food to boiling water or steam to inactivate enzymes that cause spoilage and quality loss. This heat treatment effectively slows enzymatic activity, maintaining color, texture, and nutritional value. Instant cold water shock rapidly cools blanched food, halting the cooking process and preserving firmness and vibrancy after enzyme deactivation.

Instant Cold Water Shock: A Rapid Cooling Technique Explained

Instant cold water shock is a rapid cooling technique used immediately after blanching to halt the cooking process and enhance enzyme deactivation. This method quickly reduces the temperature of vegetables, preventing overcooking and preserving nutritional quality.

Compared to traditional blanching alone, instant cold water shock improves texture and color retention by swiftly lowering the product temperature. It effectively stops enzymatic activity, ensuring extended shelf life and better sensory attributes in the final product.

Enzyme Deactivation: Why It Matters in Cooking

| Method | Effectiveness in Enzyme Deactivation | Impact on Food Quality |

|---|---|---|

| Blanching | Utilizes heat to denature enzymes such as polyphenol oxidase and peroxidase, effectively halting enzymatic reactions that cause food spoilage and discoloration. | Preserves texture and color by rapidly inactivating enzymes, crucial for maintaining nutritional value and appearance during freezing or storage. |

| Instant Cold Water Shock | Primarily stops the cooking process following blanching but does not independently deactivate enzymes; serves to preserve texture by rapidly lowering temperature. | Prevents overcooking and nutrient loss by cooling food quickly, yet enzymatic activity remains suppressed only if preceded by proper blanching. |

Blanching vs Instant Cold Water Shock: Key Differences

Blanching involves briefly boiling vegetables to deactivate enzymes and preserve color, texture, and nutrition, whereas instant cold water shock rapidly cools the blanched vegetables to halt cooking and enzyme activity. The blanching process primarily targets enzyme inactivation through heat, while cold water shock focuses on temperature reduction to stop further cooking.

Blanching ensures uniform enzyme deactivation, making it essential for food preservation and freezing, whereas instant cold water shock maintains crispness and prevents overcooking but does not inactivate enzymes alone. Combining both techniques optimizes enzyme control by applying heat for inactivation and cold water shock for rapid cooling.

Step-by-Step Blanching Method for Optimal Enzyme Control

Blanching effectively deactivates enzymes that cause spoilage and discoloration in vegetables, ensuring preservation of color and texture. Instant cold water shock immediately halts the cooking process but does not contribute significantly to enzyme deactivation.

- Heat Application - Vegetables are immersed in boiling water for a precise time to denature enzymes.

- Rapid Cooling - After blanching, immediate cooling in ice water stops heat penetration and prevents overcooking.

- Controlled Timing - Accurate blanching duration is critical for optimal enzyme inactivation without loss of nutrients or texture.

The Role of Cold Water Shock in Preserving Texture and Color

How does cold water shock enhance the preservation of texture and color after blanching? Cold water shock rapidly cools vegetables, halting the cooking process and preventing over-softening, which helps maintain a crisp texture. This sudden temperature drop also stabilizes chlorophyll and other pigments, preserving the vibrant color of blanched produce effectively.

Nutrient Retention: Blanching Versus Cold Shock Methods

Blanching effectively deactivates enzymes to preserve food quality but may cause some nutrient loss due to heat exposure. Instant cold water shock halts the cooking process quickly, which helps retain more heat-sensitive vitamins compared to prolonged blanching.

- Blanching and enzyme deactivation - Blanching applies controlled heat to inactivate enzymes that cause spoilage, ensuring food safety and shelf life extension.

- Nutrient retention differences - Instant cold water shock minimizes nutrient degradation by rapidly cooling food, maintaining higher levels of vitamin C and folate.

- Optimal preservation technique - Combining blanching with immediate cold shock maximizes enzyme deactivation while preserving essential nutrients in vegetables.

Food Safety Implications: Which Method Reigns Supreme?

Blanching effectively deactivates enzymes by exposing food to high temperatures, ensuring microbial inactivation and extending shelf life. Instant cold water shock stops the cooking process rapidly but may not eliminate all pathogens, posing potential food safety risks.

Blanching is superior for food safety because it combines enzyme inactivation with microbial reduction, reducing the risk of spoilage and foodborne illnesses. Instant cold water shock preserves texture and color but lacks sufficient pathogen control compared to blanching. Choosing blanching as a primary method improves product safety and stability in food processing.

Best Foods for Blanching and Cold Water Shock Techniques

Blanching effectively deactivates enzymes in vegetables such as green beans, broccoli, and asparagus by boiling them briefly to preserve color, texture, and nutrients. Instant cold water shock rapidly stops the cooking process by immersing blanched foods in ice water, enhancing crispness and preventing overcooking. Combining these techniques ensures optimal enzyme deactivation and maintains the freshness of produce like carrots, spinach, and peas during freezing or storage.

Related Important Terms

Sequential Hydrothermal Shock

Sequential hydrothermal shock, combining blanching and instant cold water shock, effectively inactivates enzymes by first applying controlled heat to denature proteins followed immediately by rapid cooling to halt residual enzymatic activity. This method preserves color, texture, and nutritional quality better than blanching alone, optimizing the deactivation process for vegetables and fruits.

Subzero Quenching

Blanching effectively deactivates enzymes in vegetables by applying brief heat treatment, while instant cold water shock rapidly cools the product but may not fully halt enzymatic activity. Subzero quenching, involving immersion in subzero temperature solutions, enhances enzyme inactivation beyond traditional cold water shock, improving texture preservation and color retention.

Enzymatic Thermal Arrest

Blanching effectively achieves enzymatic thermal arrest by rapidly heating produce to deactivate enzymes responsible for spoilage and quality degradation. Instant cold water shock, applied immediately after blanching, halts the cooking process, preserving texture and color while ensuring enzymes remain inactivated.

Rapid Cryogenic Plunge

Blanching effectively deactivates enzymes by applying brief heat treatment, but Rapid Cryogenic Plunge, a form of Instant Cold Water Shock, achieves faster enzyme inactivation by rapidly plunging produce into liquid nitrogen or ultra-cold solutions. This method preserves color, texture, and nutritional content more efficiently than traditional blanching followed by cold water immersion.

Temperature Gradient Deactivation

Blanching deactivates enzymes primarily through sustained heat exposure at temperatures typically between 70degC and 100degC, ensuring gradual enzyme inactivation via controlled temperature gradients. Instant cold water shock rapidly halts enzyme activity by abruptly dropping the temperature, preventing reactivation but relying less on gradual thermal deactivation mechanisms.

Immediate Ice Bath Neutralization

Blanching effectively deactivates enzymes by heating vegetables to a specific temperature, while immediate ice bath neutralization following blanching rapidly halts the cooking process, preserving texture and color. This instant cold water shock stabilizes enzyme inactivation, preventing overcooking and maintaining nutritional quality in produce.

Reactive Oxidase Stasis

Blanching effectively inactivates reactive oxidase enzymes by rapidly denaturing proteins through precise heat application, ensuring enzyme stasis and preventing oxidative browning in produce. Instant cold water shock halts thermal processes but may not fully deactivate reactive oxidase enzymes, risking residual enzyme activity and compromised product quality.

Flash Chill Blanching

Flash chill blanching offers rapid enzyme deactivation by combining high-temperature exposure with immediate cold water immersion, preserving quality and extending shelf life more effectively than traditional blanching methods. This technique minimizes nutrient loss and texture degradation compared to instant cold water shock alone, optimizing food processing efficiency.

Thermal-Enzymatic Cutoff Point

Blanching effectively inactivates enzymes by reaching the thermal-enzymatic cutoff point, a critical temperature threshold where enzyme activity sharply declines, whereas instant cold water shock primarily halts enzyme reactions by rapid cooling without sufficient thermal denaturation. Understanding the thermal-enzymatic cutoff point is essential for optimizing enzyme deactivation during blanching to prevent quality loss in vegetables.

Blanching vs Instant Cold Water Shock for enzyme deactivation Infographic

cookingdiff.com

cookingdiff.com