Blanching involves briefly boiling vegetables to deactivate enzymes, which can slightly soften their texture, while cryo-blanching uses rapid freezing to preserve the original firmness more effectively. Cryo-blanching minimizes cell damage and retains a crisp texture by reducing water loss and enzymatic activity at low temperatures. This method is particularly beneficial for delicate vegetables where maintaining a fresh, firm texture is crucial.

Table of Comparison

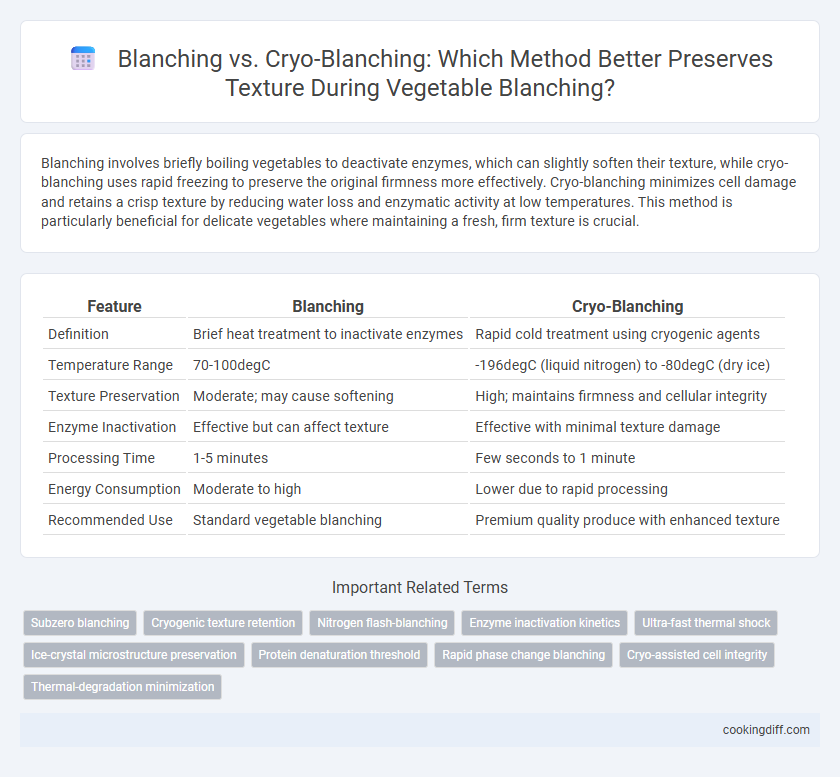

| Feature | Blanching | Cryo-Blanching |

|---|---|---|

| Definition | Brief heat treatment to inactivate enzymes | Rapid cold treatment using cryogenic agents |

| Temperature Range | 70-100degC | -196degC (liquid nitrogen) to -80degC (dry ice) |

| Texture Preservation | Moderate; may cause softening | High; maintains firmness and cellular integrity |

| Enzyme Inactivation | Effective but can affect texture | Effective with minimal texture damage |

| Processing Time | 1-5 minutes | Few seconds to 1 minute |

| Energy Consumption | Moderate to high | Lower due to rapid processing |

| Recommended Use | Standard vegetable blanching | Premium quality produce with enhanced texture |

Introduction to Blanching and Cryo-Blanching

Blanching is a thermal process that uses hot water or steam to inactivate enzymes and preserve vegetable textures before freezing or drying. Cryo-blanching employs cryogenic liquids like liquid nitrogen to rapidly cool and stabilize produce, reducing texture damage more effectively than conventional blanching.

- Conventional Blanching - Involves short-time exposure to hot water or steam to halt enzymatic activity and maintain color and firmness.

- Cryo-Blanching - Utilizes rapid freezing with cryogenic agents to better retain cellular structure and texture integrity.

- Texture Preservation - Cryo-blanching significantly reduces softening and moisture loss compared to traditional blanching methods.

The Science Behind Traditional Blanching

| Traditional blanching utilizes hot water or steam to inactivate enzymes and preserve food texture by halting cellular metabolism. The heat causes partial gelatinization of cell wall pectins and softening of cell structures, which can lead to texture degradation if overexposed. Precise control of temperature and time is essential to minimize texture loss while ensuring enzymatic inactivation. |

How Cryo-Blanching Works

Cryo-blanching uses ultra-low temperatures to quickly freeze the surface of vegetables, preserving cell structure and firmness better than traditional blanching. This method reduces thermal damage and enzymatic activity more effectively by halting biochemical processes rapidly.

- Rapid freezing - Cryo-blanching instantly lowers vegetable temperature, minimizing cell wall rupture and maintaining texture.

- Enzyme inactivation - Enzymatic degradation is stopped faster in cryo-blanching, preventing texture breakdown.

- Moisture retention - Quick surface solidification helps retain intracellular moisture, preserving crispness.

Cryo-blanching delivers superior texture preservation by combining rapid cooling with effective enzyme control.

Texture Preservation: Why It Matters

How does blanching compare to cryo-blanching in preserving texture during food processing? Blanching involves brief heat treatment that softens vegetables, often causing slight texture loss, while cryo-blanching uses rapid freezing techniques to better maintain cellular integrity. Texture preservation is critical for consumer acceptance, shelf-life extension, and maintaining nutritional quality in processed foods.

Effects of Blanching on Food Texture

Blanching involves brief exposure of food to boiling water or steam, leading to partial softening and enzyme inactivation that affects texture. Cryo-blanching utilizes cryogenic temperatures, preserving cell structure and firmness more effectively than traditional methods. Studies show cryo-blanching maintains higher texture integrity in vegetables by minimizing thermal degradation and moisture loss during processing.

Cryo-Blanching for Enhanced Texture Retention

Cryo-blanching utilizes ultra-low temperatures to halt enzymatic activity, significantly improving texture retention compared to traditional blanching methods. This technique prevents cellular damage and maintains the firmness and crispness of vegetables during processing.

Enhanced texture retention with cryo-blanching results from rapid cooling that reduces water loss and preserves cell integrity. Unlike conventional blanching, cryo-blanching minimizes tissue softening and nutrient degradation. Consequently, it offers superior quality in frozen and processed vegetables, making it ideal for maintaining desirable sensory attributes.

Nutrient Retention: Blanching vs Cryo-Blanching

Cryo-blanching significantly enhances nutrient retention compared to traditional blanching by minimizing heat exposure and enzymatic degradation. This method preserves higher levels of vitamins and antioxidants, crucial for maintaining food quality and health benefits.

- Vitamin retention - Cryo-blanching retains up to 30% more vitamin C in vegetables than conventional blanching methods.

- Antioxidant preservation - Polyphenols and flavonoids show less degradation during cryo-blanching, sustaining antioxidant capacity.

- Enzyme inactivation - Cryo-blanching effectively inactivates oxidative enzymes while preserving nutritional compounds better than hot water blanching.

Flavor and Color Impact Comparison

Blanching typically causes slight flavor loss and color fading due to heat exposure, whereas cryo-blanching uses liquid nitrogen to preserve the natural taste and vibrant color of vegetables. The rapid freezing process in cryo-blanching minimizes enzymatic activity, resulting in fresher flavor profiles and enhanced color retention compared to traditional blanching. Studies indicate that cryo-blanched produce maintains higher levels of chlorophyll and carotenoids, leading to superior sensory quality and consumer appeal.

Best Foods for Each Blanching Technique

Traditional blanching effectively preserves the texture of dense vegetables like carrots, broccoli, and green beans by inactivating enzymes that cause spoilage while maintaining firmness. These foods benefit from short, high-temperature water or steam treatments that soften cell walls without significant nutrient loss.

Cryo-blanching using liquid nitrogen is ideal for delicate foods such as berries, leafy greens, and herbs, preserving their crispness and vibrant texture by rapid freezing that prevents ice crystal formation. This method is particularly effective for products sensitive to heat, enhancing shelf life and sensory quality without texture degradation.

Related Important Terms

Subzero blanching

Subzero blanching, a form of cryo-blanching, preserves texture more effectively than traditional blanching by rapidly reducing product temperature below freezing point, minimizing cellular damage and enzymatic activity. This technique maintains crispness and firmness in vegetables by preventing the loss of turgor pressure and retarding softening processes during subsequent processing.

Cryogenic texture retention

Cryo-blanching utilizes ultra-low temperatures to rapidly halt enzymatic activity, significantly preserving the cellular structure and firmness of vegetables compared to traditional blanching. This method minimizes texture degradation by preventing cell wall damage and moisture loss, resulting in superior texture retention and enhanced crispness in processed produce.

Nitrogen flash-blanching

Nitrogen flash-blanching preserves texture more effectively than traditional blanching by rapidly cooling vegetables with liquid nitrogen, minimizing cell wall damage and maintaining firmness. The instant temperature drop in cryo-blanching reduces enzymatic activity and moisture loss, enhancing the overall quality and shelf-life of produce.

Enzyme inactivation kinetics

Blanching and cryo-blanching differ significantly in enzyme inactivation kinetics, with cryo-blanching offering more precise control over heat-sensitive enzymes like peroxidase and polyphenol oxidase, leading to superior texture preservation in vegetables. Kinetic studies reveal cryo-blanching achieves rapid enzyme denaturation at lower temperatures, minimizing cellular damage and maintaining structural integrity better than conventional hot water or steam blanching methods.

Ultra-fast thermal shock

Ultra-fast thermal shock in cryo-blanching rapidly cools food by immersion in cryogenic liquids, preserving cellular structure and maintaining firmer texture compared to traditional hot water blanching. This method reduces enzymatic activity and moisture loss, enhancing overall quality and extending shelf life.

Ice-crystal microstructure preservation

Blanching involves briefly heating vegetables to inactivate enzymes, often causing larger ice crystals that can damage cellular structures and degrade texture upon freezing. Cryo-blanching uses ultra-rapid cooling to form smaller ice crystals, effectively preserving the microstructure and maintaining superior texture integrity in frozen produce.

Protein denaturation threshold

Blanching causes protein denaturation at temperatures typically above 70degC, leading to texture softening in vegetables, while cryo-blanching uses subzero temperatures to minimize protein denaturation and better preserve firmness. The protein denaturation threshold in cryo-blanching remains largely below 0degC, effectively maintaining cellular integrity and improving texture retention compared to traditional hot water blanching.

Rapid phase change blanching

Rapid phase change blanching, as seen in cryo-blanching, preserves vegetable texture by swiftly lowering the temperature, minimizing cellular damage and enzymatic activity. Conventional blanching uses hot water or steam, causing slower heat transfer that can lead to cell wall weakening and texture degradation.

Cryo-assisted cell integrity

Cryo-blanching enhances texture preservation by rapidly freezing tissues, which stabilizes cell membranes and minimizes enzymatic degradation compared to traditional hot water blanching. The cryo-assisted cell integrity maintains firmness and reduces cellular damage, resulting in superior product quality and extended shelf life.

Blanching vs Cryo-Blanching for texture preservation Infographic

cookingdiff.com

cookingdiff.com