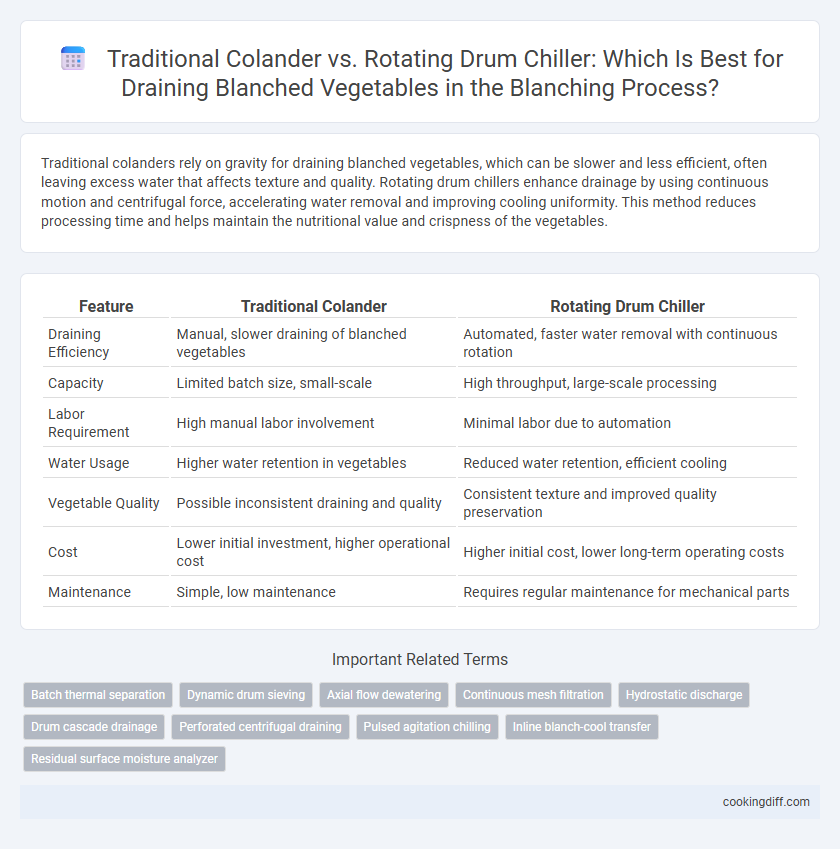

Traditional colanders rely on gravity for draining blanched vegetables, which can be slower and less efficient, often leaving excess water that affects texture and quality. Rotating drum chillers enhance drainage by using continuous motion and centrifugal force, accelerating water removal and improving cooling uniformity. This method reduces processing time and helps maintain the nutritional value and crispness of the vegetables.

Table of Comparison

| Feature | Traditional Colander | Rotating Drum Chiller |

|---|---|---|

| Draining Efficiency | Manual, slower draining of blanched vegetables | Automated, faster water removal with continuous rotation |

| Capacity | Limited batch size, small-scale | High throughput, large-scale processing |

| Labor Requirement | High manual labor involvement | Minimal labor due to automation |

| Water Usage | Higher water retention in vegetables | Reduced water retention, efficient cooling |

| Vegetable Quality | Possible inconsistent draining and quality | Consistent texture and improved quality preservation |

| Cost | Lower initial investment, higher operational cost | Higher initial cost, lower long-term operating costs |

| Maintenance | Simple, low maintenance | Requires regular maintenance for mechanical parts |

Introduction to Blanching and Draining Techniques

| Blanching involves briefly boiling vegetables to deactivate enzymes, preserving color and texture, followed by rapid cooling to halt cooking. Traditional colanders rely on manual shaking and gravity for draining, often resulting in inconsistent water removal and longer processing times. Rotating drum chillers use automated rotation and centrifugal force to efficiently drain water, enhancing throughput and maintaining vegetable quality in large-scale operations. |

Understanding the Traditional Colander Method

The traditional colander method for draining blanched vegetables relies on manual shaking or tapping to remove excess water. This technique is simple and cost-effective but may result in inconsistent moisture removal compared to mechanized options. Efficiency depends heavily on operator skill and vegetable type, making it less suitable for large-scale processing.

What is a Rotating Drum Chiller?

A Rotating Drum Chiller is an advanced piece of equipment used to cool and drain blanched vegetables efficiently. It uses a rotating drum mechanism to ensure continuous washing and cooling, improving vegetable quality and processing speed.

- Continuous operation - The rotating drum allows for nonstop processing, reducing labor and downtime compared to traditional colanders.

- Improved drainage - Water is efficiently removed from vegetables by centrifugal force during rotation, leading to faster drying times.

- Enhanced cooling - Constant water circulation inside the drum quickly lowers the temperature of blanched vegetables, preventing overcooking.

This technology increases production efficiency while maintaining the nutritional quality of blanched vegetables.

Efficiency and Speed: Colander vs Rotating Drum Chiller

Which method offers superior efficiency and speed for draining blanched vegetables, the traditional colander or the rotating drum chiller? The rotating drum chiller significantly enhances throughput by continuously draining and cooling vegetables, reducing labor and processing time compared to manual colander use. This automated system also minimizes product handling, leading to improved hygiene and consistent quality in high-volume food processing operations.

Impact on Vegetable Quality and Texture

Traditional colanders often cause uneven water drainage leading to inconsistent texture in blanched vegetables. Rotating drum chillers provide continuous agitation and uniform water removal, maintaining crispness and preventing sogginess. Studies indicate that rotating drum chillers better preserve cell structure and color, enhancing overall vegetable quality post-blanching.

Ease of Use and User Safety Concerns

The traditional colander requires manual handling and lifting, increasing the risk of repetitive strain injuries and accidental spills during the draining process. Users need to be cautious of hot water exposure, which poses burn hazards without proper protective gear.

The rotating drum chiller offers automated drainage with minimal manual intervention, significantly reducing physical effort and enhancing user safety. Its enclosed design limits direct contact with hot vegetables and liquids, lowering the chances of burns and slips in commercial kitchens.

Water and Energy Consumption Compared

The rotating drum chiller significantly reduces water consumption compared to the traditional colander, enhancing sustainability in blanching processes. Energy usage is optimized in the rotating drum system due to its efficient design, lowering overall operational costs.

- Water Consumption Efficiency - The rotating drum chiller uses closed-loop water systems, minimizing water waste relative to the open draining method of traditional colanders.

- Energy Usage Reduction - The rotating drum chiller's continuous movement requires less mechanical energy than manual handling involved in traditional colanders.

- Operational Sustainability - By lowering water and energy consumption, the rotating drum chiller supports eco-friendly vegetable processing with reduced environmental impact.

Cleaning and Maintenance: Which is Simpler?

The traditional colander requires manual cleaning, often involving disassembly and scrubbing to remove vegetable residues, which can be time-consuming. In contrast, rotating drum chillers feature automated or semi-automated cleaning systems that reduce labor and improve sanitation efficiency.

Maintenance for traditional colanders is straightforward but frequent, with wear and tear on metal parts necessitating regular inspection. Rotating drum chillers benefit from built-in self-cleaning mechanisms that minimize downtime and maintain consistent hygiene standards. Overall, rotating drum chillers offer a simpler and more efficient cleaning and maintenance process for blanched vegetable draining operations.

Suitability for Home vs Commercial Kitchens

Traditional colanders are well-suited for home kitchens due to their simplicity and low cost, making them ideal for small batch blanching. Rotating drum chillers offer superior capacity and continuous draining, catering to the high-volume demands of commercial kitchens.

- Traditional colanders - Provide ease of use and quick cleanup for occasional blanching tasks in domestic settings.

- Rotating drum chillers - Enable efficient water drainage and cooling in large-scale vegetable processing operations.

- Operational scale - Traditional colanders excel in manual, small-scale use while rotating drum chillers optimize automated, industrial workflows.

Related Important Terms

Batch thermal separation

Traditional colanders rely on gravitational draining in batch thermal separation, often resulting in uneven moisture removal and longer processing times. Rotating drum chillers enhance efficiency by mechanically agitating blanched vegetables, ensuring uniform water extraction and faster cooling within continuous batch cycles.

Dynamic drum sieving

Dynamic drum sieving in a rotating drum chiller enhances the draining efficiency of blanched vegetables by continuously agitating and separating water from the product, unlike the static draining process of a traditional colander. This dynamic movement reduces drying time and improves product quality by minimizing residual moisture and preventing vegetable damage during drainage.

Axial flow dewatering

Traditional colanders rely on gravity and manual shaking to drain blanched vegetables, resulting in slower water removal and inconsistent axial flow dewatering. In contrast, rotating drum chillers use centrifugal force to enhance axial flow, enabling rapid and uniform drainage that preserves vegetable texture and reduces processing time.

Continuous mesh filtration

The rotating drum chiller features continuous mesh filtration that enables efficient draining and cooling of blanched vegetables without interruption, reducing water usage and minimizing vegetable damage. Traditional colanders lack this continuous filtration system, resulting in slower drainage and less consistent cooling, which can compromise vegetable quality and processing speed.

Hydrostatic discharge

Traditional colanders rely on gravity-driven drainage, often leading to slower hydrostatic discharge and residual water retention on blanched vegetables, which can affect texture and shelf life. Rotating drum chillers enhance hydrostatic discharge through continuous agitation and centrifugal force, promoting faster water removal and improved vegetable quality during post-blanching processing.

Drum cascade drainage

The rotating drum chiller utilizes drum cascade drainage to efficiently remove water from blanched vegetables, ensuring faster drying and minimal nutrient loss compared to traditional colanders, which rely on gravity and manual shaking. This mechanized process enhances throughput and maintains vegetable quality by providing consistent, even drainage within an enclosed system.

Perforated centrifugal draining

Perforated centrifugal draining in a rotating drum chiller enhances the efficiency of water removal from blanched vegetables by combining high-speed rotation with perforated surfaces, significantly reducing moisture retention compared to the traditional colander method. This mechanized process improves throughput and uniformity, minimizing vegetable damage and optimizing quality for subsequent processing stages.

Pulsed agitation chilling

Pulsed agitation chilling in rotating drum chillers enhances water flow dynamics and vegetable contact, significantly increasing drainage efficiency compared to traditional colander methods. This technology reduces moisture retention and shortens drying times, optimizing post-blanching vegetable quality and shelf life.

Inline blanch-cool transfer

The rotating drum chiller offers more efficient inline blanch-cool transfer by continuously moving vegetables, reducing cooling time and minimizing microbial growth compared to the traditional colander, which relies on batch draining and exposes vegetables to longer heat retention. This mechanized process improves throughput and preserves vegetable texture and color, enhancing overall product quality in high-volume industrial food processing.

Traditional colander vs Rotating drum chiller for draining blanched vegetables. Infographic

cookingdiff.com

cookingdiff.com