A stainless steel mixing bowl is ideal for an ice bath after blanching due to its durability and excellent temperature retention, keeping the water colder for longer periods. Plastic bowls, while lightweight and often less expensive, may not maintain the ice bath's cold temperature as effectively and can be prone to staining or odor retention. Choosing a stainless steel bowl ensures better food safety and longevity, making it the preferred option for cooling vegetables quickly and efficiently.

Table of Comparison

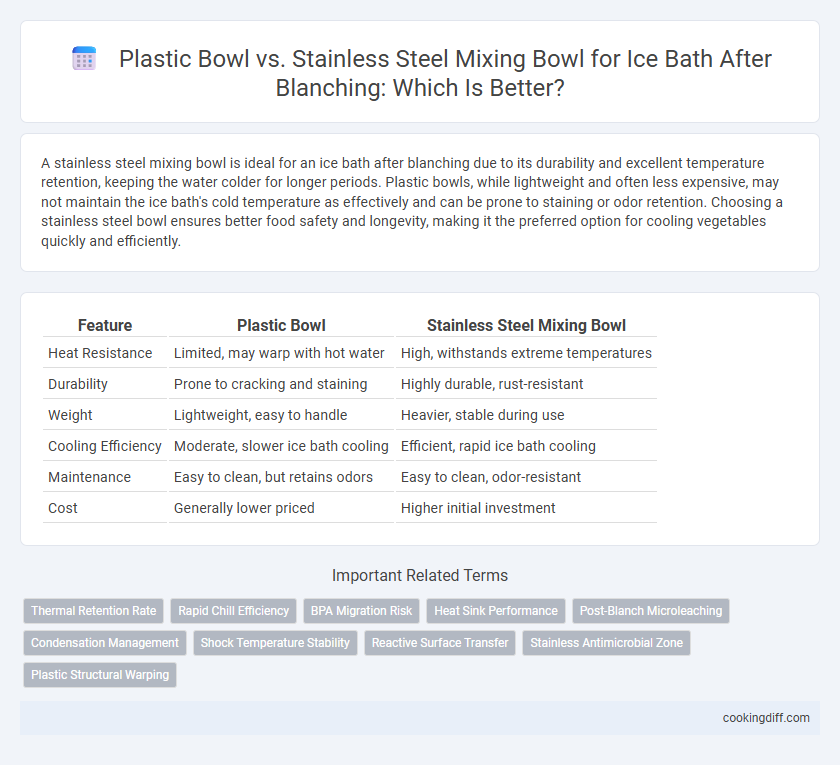

| Feature | Plastic Bowl | Stainless Steel Mixing Bowl |

|---|---|---|

| Heat Resistance | Limited, may warp with hot water | High, withstands extreme temperatures |

| Durability | Prone to cracking and staining | Highly durable, rust-resistant |

| Weight | Lightweight, easy to handle | Heavier, stable during use |

| Cooling Efficiency | Moderate, slower ice bath cooling | Efficient, rapid ice bath cooling |

| Maintenance | Easy to clean, but retains odors | Easy to clean, odor-resistant |

| Cost | Generally lower priced | Higher initial investment |

Understanding the Ice Bath Method in Blanching

Stainless steel mixing bowls are preferred for ice baths after blanching due to their superior durability and ability to maintain consistent cold temperatures. Plastic bowls may retain residual heat and can sometimes warp under extreme temperature changes, reducing the effectiveness of the ice bath in rapidly cooling vegetables. Using a stainless steel bowl ensures a more efficient shock cooling process, preserving texture and color by quickly halting the cooking process.

Key Roles of Mixing Bowls in Ice Bath Preparation

Stainless steel mixing bowls excel in ice bath preparation for blanching due to their superior thermal conductivity, rapidly cooling vegetables and preserving texture and color. Plastic bowls, although lightweight and less expensive, often provide poorer temperature retention, potentially slowing the cooling process and affecting food quality. Selecting stainless steel bowls ensures more efficient cooling performance essential for maintaining optimal blanching results.

Plastic Bowls: Pros and Cons for Ice Baths

Plastic bowls are lightweight and less expensive, making them convenient for setting up ice baths after blanching. They are less likely to conduct cold, which can help maintain water temperature longer.

However, plastic bowls may retain odors and stains from repeated use, affecting food quality. They are less durable than stainless steel and can crack or warp when exposed to extreme temperatures. Despite these drawbacks, their affordability and ease of handling make them a popular choice for home cooks.

Stainless Steel Bowls: Advantages and Disadvantages

Stainless steel bowls are highly durable and resistant to heat, making them ideal for ice baths after blanching. Their non-porous surface prevents odor absorption and ensures easy cleaning compared to plastic bowls.

- Heat Resistance - Stainless steel withstands extreme temperatures without warping or melting, ensuring safety during ice baths.

- Durability - These bowls are less prone to cracking or staining over time, offering long-term usability.

- Conductivity - Stainless steel's high thermal conductivity cools water faster but can also transfer cold to hands, requiring caution.

Thermal Conductivity: Plastic vs Stainless Steel Bowls

| Material | Thermal Conductivity (W/m*K) | Effectiveness in Ice Bath |

|---|---|---|

| Plastic Bowl | 0.2 - 0.5 | Low thermal conductivity slows cooling, less efficient for rapid temperature drop after blanching |

| Stainless Steel Bowl | 15 - 20 | High thermal conductivity facilitates faster heat transfer, promotes quicker cooling in ice baths |

Durability and Longevity in Kitchen Use

Stainless steel mixing bowls offer superior durability and resistance to warping or cracking when used in ice baths after blanching, maintaining their structural integrity over time. Plastic bowls, although lightweight, are more prone to damage from prolonged exposure to cold temperatures and repeated use, which can reduce their longevity in kitchen applications.

The non-reactive nature of stainless steel ensures it does not absorb odors or stains, preserving its appearance and functionality for years. In contrast, plastic bowls may degrade or discolor faster, especially with frequent blanching processes involving temperature shock.

Food Safety Considerations: Plastic and Stainless Steel

Plastic bowls may harbor bacteria if scratched or cracked during blanching ice baths, making them less ideal for maintaining strict food safety standards. Stainless steel mixing bowls resist damage better and are non-porous, providing a safer environment to rapidly cool vegetables and prevent contamination.

Stainless steel is also easier to sanitize and can withstand high temperatures, ensuring thorough cleaning between uses. Plastic bowls can absorb odors and dyes from foods, increasing the risk of cross-contamination in repeated blanching processes.

Ease of Cleaning and Maintenance

Which is easier to clean and maintain after using for an ice bath in blanching: plastic bowls or stainless steel mixing bowls? Stainless steel bowls resist staining and odors better, making cleanup faster and more hygienic. Plastic bowls can absorb food colors and retain smells, requiring more intensive cleaning and regular replacement to avoid contamination.

Cost Comparison: Plastic vs Stainless Steel Mixing Bowls

Plastic mixing bowls generally have a lower upfront cost compared to stainless steel bowls, making them a budget-friendly option for blanched vegetable ice baths. Stainless steel bowls, although more expensive initially, offer greater durability and longevity, potentially reducing replacement costs over time.

- Initial Cost Difference - Plastic bowls typically cost 30-50% less than stainless steel alternatives.

- Durability Impact - Stainless steel bowls resist cracks and warping, extending usable lifespan beyond plastic bowls.

- Long-Term Investment - Higher initial investment in stainless steel can lead to cost savings due to less frequent replacement needed.

Related Important Terms

Thermal Retention Rate

Stainless steel mixing bowls exhibit a higher thermal retention rate compared to plastic bowls, maintaining cold temperatures longer during ice baths after blanching. This superior heat conductivity ensures rapid cooling of vegetables, enhancing texture and color retention.

Rapid Chill Efficiency

Stainless steel mixing bowls provide superior rapid chill efficiency for ice baths after blanching due to their excellent thermal conductivity, enabling faster heat transfer and quicker cooling of vegetables. Plastic bowls, with lower thermal conductivity, retain heat longer and slow down the chilling process, potentially affecting the quality and texture of blanched produce.

BPA Migration Risk

Stainless steel mixing bowls eliminate BPA migration risks commonly associated with plastic bowls during ice baths after blanching, ensuring safer food preservation by preventing chemical leaching. Plastic bowls, especially those not BPA-free, can release harmful substances when exposed to cold temperatures, compromising food safety and quality.

Heat Sink Performance

Stainless steel mixing bowls offer superior heat sink performance compared to plastic bowls due to their higher thermal conductivity, enabling faster and more efficient cooling during ice baths after blanching. This rapid temperature reduction helps preserve texture, color, and nutrient retention in vegetables more effectively than plastic bowls, which insulate heat and slow the cooling process.

Post-Blanch Microleaching

Stainless steel mixing bowls are preferred over plastic bowls for ice baths after blanching due to their non-porous surface, which minimizes post-blanch microleaching of chemicals into food. Plastic bowls may harbor residual contaminants and absorb heat unevenly, potentially increasing the risk of harmful leachates during rapid cooling.

Condensation Management

Stainless steel mixing bowls excel in condensation management during ice baths after blanching due to their non-porous surface and superior thermal conductivity, which minimizes water accumulation and maintains consistent cooling. In contrast, plastic bowls tend to retain condensation on their surfaces, potentially causing uneven cooling and increased water spillage.

Shock Temperature Stability

Stainless steel mixing bowls exhibit superior shock temperature stability compared to plastic bowls, effectively withstanding rapid temperature changes during ice baths after blanching. This durability ensures consistent cooling rates and prevents potential cracking or warping that can occur with plastic bowls under extreme thermal stress.

Reactive Surface Transfer

Stainless steel mixing bowls offer a non-reactive surface that prevents metal ion transfer during ice baths after blanching, ensuring the food's flavor and color remain unaltered. In contrast, plastic bowls minimize reactive surface transfer but may retain odors and are less durable, affecting long-term use for rapid cooling.

Stainless Antimicrobial Zone

Stainless steel mixing bowls offer an antimicrobial zone that inhibits bacterial growth, ensuring safer and more hygienic ice baths after blanching compared to plastic bowls. This antimicrobial property enhances food safety by reducing contamination risks during rapid cooling processes.

Plastic bowl vs Stainless steel mixing bowl for ice bath after blanching. Infographic

cookingdiff.com

cookingdiff.com