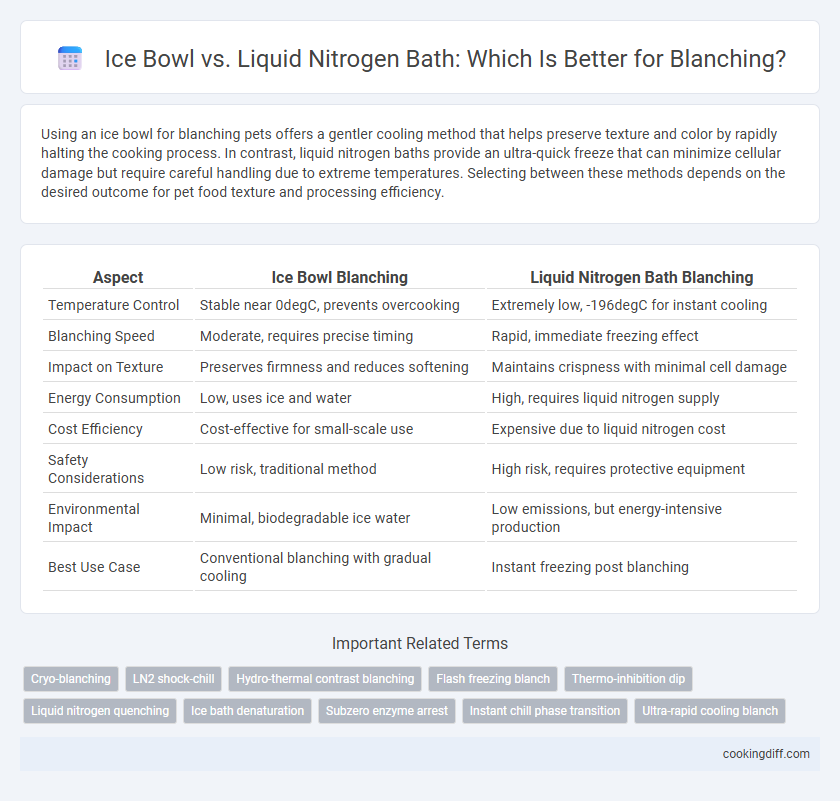

Using an ice bowl for blanching pets offers a gentler cooling method that helps preserve texture and color by rapidly halting the cooking process. In contrast, liquid nitrogen baths provide an ultra-quick freeze that can minimize cellular damage but require careful handling due to extreme temperatures. Selecting between these methods depends on the desired outcome for pet food texture and processing efficiency.

Table of Comparison

| Aspect | Ice Bowl Blanching | Liquid Nitrogen Bath Blanching |

|---|---|---|

| Temperature Control | Stable near 0degC, prevents overcooking | Extremely low, -196degC for instant cooling |

| Blanching Speed | Moderate, requires precise timing | Rapid, immediate freezing effect |

| Impact on Texture | Preserves firmness and reduces softening | Maintains crispness with minimal cell damage |

| Energy Consumption | Low, uses ice and water | High, requires liquid nitrogen supply |

| Cost Efficiency | Cost-effective for small-scale use | Expensive due to liquid nitrogen cost |

| Safety Considerations | Low risk, traditional method | High risk, requires protective equipment |

| Environmental Impact | Minimal, biodegradable ice water | Low emissions, but energy-intensive production |

| Best Use Case | Conventional blanching with gradual cooling | Instant freezing post blanching |

Introduction to Blanching: Why Cooling Methods Matter

Blanching involves briefly cooking vegetables followed by rapid cooling to halt enzyme activity and preserve quality. The choice of cooling method significantly impacts texture, color, and nutrient retention during this process.

Ice bowls provide an accessible and effective means for cooling by surrounding produce with ice and water, ensuring uniform temperature drop. Liquid nitrogen baths cool products much faster due to extremely low temperatures, minimizing cooking time but requiring specialized handling and safety measures.

Ice Bowl vs Liquid Nitrogen Bath: Key Differences

Ice bowl blanching involves submerging food in cold water and ice to rapidly cool it after hot water blanching, slowing enzymatic activity and preserving color and texture. Liquid nitrogen bath blanching uses ultra-cold nitrogen to freeze food instantly, offering quicker cooling but requiring specialized equipment and handling precautions.

The key differences include cooling speed, with liquid nitrogen providing almost instantaneous temperature drop compared to slower ice bowl cooling. Ice bowl methods are more accessible and cost-effective for small-scale or home use, whereas liquid nitrogen baths are preferred for industrial applications demanding high efficiency and product quality.

Speed of Cooling: Ice vs Nitrogen

Liquid nitrogen bath provides an exceptionally rapid cooling rate for blanching, often reducing the temperature of vegetables within seconds due to its extremely low temperature of -196degC. In contrast, an ice bowl cools more slowly, generally stabilizing the product temperature around 0degC, which can extend the cooling process by several minutes. The faster speed of cooling with liquid nitrogen helps preserve texture and nutrient content better than traditional ice bowl methods.

Impact on Food Quality and Texture

Ice bowl blanching slows enzyme activity while preserving texture moderately, but may result in slight nutrient loss due to prolonged exposure. Liquid nitrogen baths rapidly halt enzymatic reactions, ensuring superior retention of color, flavor, and crispness in blanched foods.

- Ice bowl blanching - Provides gradual cooling that may cause partial texture softening and nutrient degradation.

- Liquid nitrogen bath - Instantly freezes food, maintaining cellular structure and enhancing overall texture quality.

- Food quality impact - Liquid nitrogen preserves sensory attributes better than ice bowl methods due to rapid temperature reduction.

Safety Considerations: Handling Ice and Liquid Nitrogen

Handling ice in blanching is generally safer due to its non-volatile nature and minimal risk of causing burns. Liquid nitrogen requires stringent safety measures because of its extremely low temperature and potential for causing severe cold burns or asphyxiation if not handled properly.

- Ice poses minimal risk - Its solid state and higher temperature reduce hazards during blanching operations.

- Liquid nitrogen demands protective gear - Operators must use insulating gloves and face shields to prevent cold burns and frostbite.

- Ventilation is critical with liquid nitrogen - Adequate airflow prevents oxygen displacement and reduces asphyxiation hazards in enclosed spaces.

Equipment and Accessibility: Home vs Professional Kitchens

Which blanching method offers better equipment and accessibility for home cooks versus professional kitchens? Ice bowl blanching requires minimal equipment and is easily accessible for home kitchens, using simple tools like bowls filled with ice and water. Liquid nitrogen baths need specialized, costly equipment and safety measures, making them more suitable for professional kitchens with trained staff and proper facilities.

Cost Comparison: Ice Bowl and Liquid Nitrogen Bath

Ice bowl blanching offers a cost-effective solution with minimal equipment expenses and lower operating costs compared to liquid nitrogen baths. Liquid nitrogen, while providing rapid cooling, incurs higher costs due to the price of the cryogenic liquid and specialized containment systems.

Operational expenses for ice bowls primarily include water and ice, which are inexpensive and readily available, making them suitable for small to medium-scale food processing. In contrast, liquid nitrogen baths require continuous supply of liquid nitrogen, significantly raising the overall treatment cost. Businesses must weigh these cost differences against processing speed and product quality when choosing the blanching method.

Environmental Impact of Cooling Methods

| Ice Bowl | Utilizes large quantities of water and ice, leading to significant water consumption and potential waste management challenges. Energy consumption is moderate, dependent on ice production methods, with possible environmental impact from refrigeration systems. |

| Liquid Nitrogen Bath | Offers rapid cooling with minimal water usage, reducing water waste but relies on production of liquid nitrogen, which is energy-intensive and associated with greenhouse gas emissions. Overall carbon footprint depends on sourcing and transportation of liquid nitrogen. |

Best Use Cases: When to Use Each Method

Ice bowl blanching is best suited for vegetables that require gentle cooling to preserve texture and color, such as green beans and broccoli, making it ideal for home kitchens and small-scale operations. Liquid nitrogen baths offer rapid freezing and blanching, perfect for delicate produce and preserving nutritional content in high-volume industrial food processing. Choosing between the two depends on the desired cooling speed, product sensitivity, and processing scale.

Related Important Terms

Cryo-blanching

Cryo-blanching using liquid nitrogen bath rapidly freezes vegetables, preserving texture, color, and nutrient retention better than traditional ice bowl blanching, which cools produce more slowly and can lead to nutrient leaching. Liquid nitrogen's ultra-low temperature (-196degC) enables instantaneous enzyme inactivation, reducing oxidative damage and enhancing shelf life compared to the conventional ice bowl method.

LN2 shock-chill

Liquid nitrogen (LN2) shock-chill offers rapid temperature reduction during blanching, preserving texture, color, and nutritional content more effectively than traditional ice bowl methods. Its extreme cold (-196degC) minimizes enzyme activity and microbial growth, resulting in superior quality and extended shelf-life for blanched vegetables.

Hydro-thermal contrast blanching

Hydro-thermal contrast blanching using an ice bowl maintains cellular structure by rapidly reducing temperature after brief heat exposure, preventing enzymatic degradation more effectively than liquid nitrogen baths, which may cause cellular damage due to extreme cold shock. The ice bowl method ensures optimal texture retention and nutrient preservation in vegetables by balancing thermal stress and cooling rate during blanching processes.

Flash freezing blanch

Ice bowl blanching rapidly cools vegetables after hot water or steam blanching, but liquid nitrogen bath offers superior flash freezing by instantly dropping temperatures below -196degC, preserving texture and nutritional quality far more effectively. The rapid thermal shock in liquid nitrogen minimizes ice crystal formation, making it the preferred method for high-quality blanching and freezing in industrial food processing.

Thermo-inhibition dip

The thermo-inhibition dip in blanching using an ice bowl maintains vegetable texture and color by rapidly reducing temperature to around 0-4degC, effectively halting enzymatic activity without causing thermal shock. In contrast, a liquid nitrogen bath offers ultra-fast cooling at -196degC, preserving nutrients and crispness but risks surface damage due to extreme thermal stress during the blanching process.

Liquid nitrogen quenching

Liquid nitrogen quenching in blanching rapidly reduces product temperature, preserving texture, color, and nutritional value better than traditional ice bowl methods by minimizing enzymatic activity and microbial growth. Its ultra-fast cooling also prevents moisture loss and ensures superior quality in vegetables and fruits during processing.

Ice bath denaturation

Ice bowl blanching effectively slows enzymatic activity by rapidly cooling vegetables post-blanching but can cause partial protein denaturation due to slower heat removal compared to liquid nitrogen baths. Liquid nitrogen baths minimize protein denaturation by rapidly freezing tissues, preserving texture and nutrient content more efficiently than traditional ice baths.

Subzero enzyme arrest

Ice bowl blanching slows enzyme activity by cooling vegetables to near 0degC, but does not fully arrest enzymatic reactions, whereas liquid nitrogen baths rapidly freeze produce to subzero temperatures below -196degC, effectively halting enzyme activity instantaneously and preserving cellular integrity. The extreme subzero environment in liquid nitrogen baths prevents enzymatic degradation and extends shelf life far more efficiently than ice bowl methods.

Instant chill phase transition

Ice bowl blanching achieves slower cooling rates during the instant chill phase transition, leading to prolonged enzyme activity and potential texture degradation. Liquid nitrogen baths provide rapid phase transition by instant freezing, minimizing enzymatic reactions and preserving cellular structure more effectively.

Ice bowl vs Liquid nitrogen bath for blanching. Infographic

cookingdiff.com

cookingdiff.com