Blanching involves briefly boiling vegetables to inactivate enzymes and preserve color, texture, and nutrients, while steam infusion uses high-pressure steam to rapidly heat food without direct water contact, maintaining flavor and moisture. Compared to blanching, steam infusion offers faster cooking times and reduces nutrient loss due to minimal leaching. Both methods prepare foods for freezing or further cooking, but steam infusion enhances energy efficiency and product quality through gentle, uniform heat transfer.

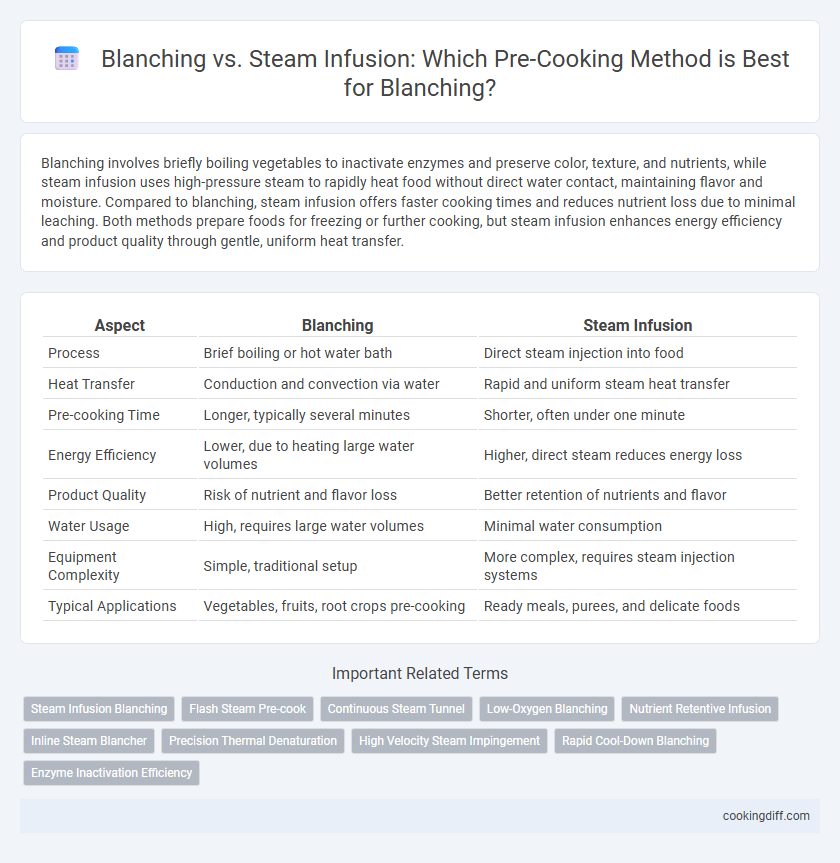

Table of Comparison

| Aspect | Blanching | Steam Infusion |

|---|---|---|

| Process | Brief boiling or hot water bath | Direct steam injection into food |

| Heat Transfer | Conduction and convection via water | Rapid and uniform steam heat transfer |

| Pre-cooking Time | Longer, typically several minutes | Shorter, often under one minute |

| Energy Efficiency | Lower, due to heating large water volumes | Higher, direct steam reduces energy loss |

| Product Quality | Risk of nutrient and flavor loss | Better retention of nutrients and flavor |

| Water Usage | High, requires large water volumes | Minimal water consumption |

| Equipment Complexity | Simple, traditional setup | More complex, requires steam injection systems |

| Typical Applications | Vegetables, fruits, root crops pre-cooking | Ready meals, purees, and delicate foods |

Introduction to Pre-Cooking Methods

Blanching is a traditional pre-cooking method involving brief immersion in boiling water or steam to halt enzymatic activity and soften food, ensuring color and texture preservation. Steam infusion, a newer technology, rapidly heats food using steam in a low-oxygen environment, enhancing heat transfer efficiency and reducing cooking time. Both methods prepare ingredients for further processing but differ significantly in energy consumption, nutrient retention, and product quality outcomes.

Understanding Blanching: Fundamentals and Techniques

Blanching is a thermal process involving brief exposure to boiling water or steam to inactivate enzymes and preserve food quality, primarily used before freezing or drying. Steam infusion utilizes pressurized steam to pre-cook food rapidly while maintaining texture and flavor, offering a more energy-efficient alternative.

- Blanching Processes - Typically involves immersion in hot water or direct steam for a set time to halt enzymatic activity and reduce microbial load.

- Steam Infusion Technique - Uses high-pressure steam injection that envelops food, enabling faster heat penetration and uniform cooking compared to traditional blanching.

- Quality and Efficiency - Blanching can lead to nutrient leaching and longer processing times, whereas steam infusion minimizes nutrient loss and improves energy consumption.

What is Steam Infusion in Cooking?

| Steam Infusion in Cooking | Steam infusion is a cooking technique that uses a high-velocity flow of steam to rapidly heat and cook food, providing precise temperature control and enhanced flavor retention. |

| Comparison to Blanching | Unlike traditional blanching, which involves submerging food in boiling water, steam infusion minimizes nutrient loss and reduces cooking time by directly exposing food to steam without water immersion. |

| Benefits | Steam infusion maintains texture and color more effectively, streamlines pre-cooking processes, and is ideal for delicate vegetables and fruits requiring gentle heat application. |

Nutrient Retention: Blanching vs Steam Infusion

Blanching often leads to significant nutrient loss due to water leaching, especially of water-soluble vitamins like vitamin C and B-complex. Steam infusion preserves more nutrients by minimizing direct contact with water and reducing cooking time.

- Vitamin Retention - Steam infusion retains up to 30% more vitamin C compared to traditional blanching methods.

- Mineral Preservation - Minerals such as potassium and magnesium are better maintained with steam infusion due to less nutrient leaching.

- Flavor and Texture - Steam infusion helps preserve natural flavor and crispness by reducing nutrient and moisture loss during pre-cooking.

Impact on Color and Flavor Preservation

Blanching involves brief exposure to boiling water or steam, which can cause slight leaching of pigments, leading to some color fading in vegetables. Steam infusion, utilizing steam directly injected at controlled temperatures, better preserves the vibrant colors by minimizing water contact and pigment loss.

Flavor compounds tend to dissipate during blanching due to prolonged heat and water exposure, often resulting in a milder taste. Steam infusion maintains more robust natural flavors by reducing thermal degradation and nutrient leaching, enhancing overall product quality.

Efficiency and Time Comparison

Blanching and steam infusion are both pre-cooking techniques used to preserve food quality, but they differ significantly in efficiency and processing time. Steam infusion typically offers faster heat transfer, reducing cooking time compared to traditional blanching methods.

- Heat Transfer Mechanism - Steam infusion uses direct steam contact for rapid and uniform heating, enhancing efficiency over hot water blanching.

- Processing Time - Steam infusion can reduce pre-cooking time by up to 50%, improving throughput in food processing operations.

- Energy Consumption - Steam infusion generally consumes less energy due to shorter cooking cycles and efficient steam utilization.

Choosing between blanching and steam infusion depends on balancing speed, quality retention, and equipment availability in production settings.

Energy Usage and Sustainability

Blanching typically consumes more water and energy compared to steam infusion, as it involves prolonged heating and cooling cycles that generate significant waste water. Steam infusion uses direct steam injection, which enhances heat transfer efficiency and reduces overall energy consumption.

Steam infusion's lower energy usage contributes to a smaller carbon footprint, making it a more sustainable option for pre-cooking processes. The method also minimizes water usage and wastewater production, aligning with environmental regulations and corporate sustainability goals. As a result, steam infusion is increasingly preferred in food processing facilities aiming to optimize energy efficiency and sustainability.

Food Safety Considerations

How do blanching and steam infusion compare in terms of food safety considerations for pre-cooking? Blanching effectively inactivates enzymes and reduces microbial load by immersing food in boiling water, ensuring a significant reduction of pathogens. Steam infusion uses pressurized steam which rapidly heats the food, providing uniform heat distribution and maintaining food safety by minimizing contamination risks during processing.

Suitable Food Types for Each Method

Blanching is ideal for vegetables like green beans, spinach, and broccoli that benefit from quick, high-heat exposure to preserve color and texture. Steam infusion suits delicate foods such as seafood, fruits, and thinly sliced vegetables, as it gently cooks without water contact, maintaining flavor and nutrients. Choosing between blanching and steam infusion depends on the food's texture sensitivity and desired nutrient retention during pre-cooking.

Related Important Terms

Steam Infusion Blanching

Steam infusion blanching uses direct steam injection to rapidly heat and pre-cook food products, preserving nutrient content and texture better than traditional water blanching methods. This technique reduces processing time and water usage while enhancing product quality and shelf life compared to conventional blanching processes.

Flash Steam Pre-cook

Flash steam pre-cook utilizes high-pressure steam applied rapidly to food, preserving nutrients and texture better than traditional blanching methods, which often involve prolonged water immersion and heat exposure. This technique reduces cooking time and water usage while enhancing color stability and microbial safety in vegetables.

Continuous Steam Tunnel

Continuous steam tunnel blanching offers consistent temperature control and efficient heat transfer, reducing cooking time and nutrient loss during pre-cooking compared to traditional steam infusion methods. This method ensures uniform product quality and higher throughput, making it ideal for industrial-scale food processing applications.

Low-Oxygen Blanching

Low-oxygen blanching preserves nutrient retention and color quality by minimizing oxidative degradation during pre-cooking, outperforming traditional steam infusion methods that tend to expose food to higher oxygen levels. This technique enhances shelf life and texture stability by creating an inert environment, reducing enzymatic activity more effectively than conventional steam infusion processes.

Nutrient Retentive Infusion

Blanching often leads to significant nutrient loss due to prolonged exposure to hot water, whereas steam infusion preserves vitamins and antioxidants by using controlled steam temperatures that minimize leaching. Steam infusion enhances nutrient retention by reducing cooking time and maintaining cell structure, benefiting pre-cooked vegetables and fruits with higher nutritional quality.

Inline Steam Blancher

Inline steam blanchers offer precise temperature control and rapid heat transfer, reducing nutrient loss and enhancing product texture compared to traditional blanching methods. Steam infusion technology accelerates pre-cooking by enveloping food items with high-velocity steam, promoting uniform cooking and improved energy efficiency.

Precision Thermal Denaturation

Blanching provides controlled thermal exposure that achieves precise protein denaturation by maintaining consistent temperature and time parameters, crucial for preserving texture and nutritional quality. Steam infusion offers rapid, uniform heat transfer enabling precise thermal denaturation with reduced time, minimizing nutrient loss and enhancing flavor retention.

High Velocity Steam Impingement

High velocity steam impingement during blanching delivers rapid and uniform heat transfer, significantly reducing processing time and preserving the nutritional quality of vegetables compared to traditional steam infusion methods. This technique enhances enzyme inactivation and color retention by creating intense steam jets that penetrate surfaces, optimizing pre-cooking efficiency and product texture.

Rapid Cool-Down Blanching

Rapid cool-down blanching reduces enzyme activity swiftly by immersing vegetables in hot water followed by immediate cooling, preserving color and texture more effectively than steam infusion. This method ensures precise temperature control and minimizes nutrient loss, making it ideal for pre-cooking applications where quality retention is crucial.

Blanching vs Steam Infusion for pre-cooking. Infographic

cookingdiff.com

cookingdiff.com