Blanching effectively reduces surface fat in food products by using hot water or steam, which loosens fats and facilitates their removal, while maltodextrin dusting absorbs free fats on the surface without altering the food's texture. Compared to blanching, maltodextrin dusting serves as a dry method that preserves moisture and flavor better, making it suitable for delicate items that might lose quality through heat exposure. Both techniques aid in fat reduction, but blanching provides a more thorough cleaning, whereas maltodextrin dusting offers a quick, low-impact alternative.

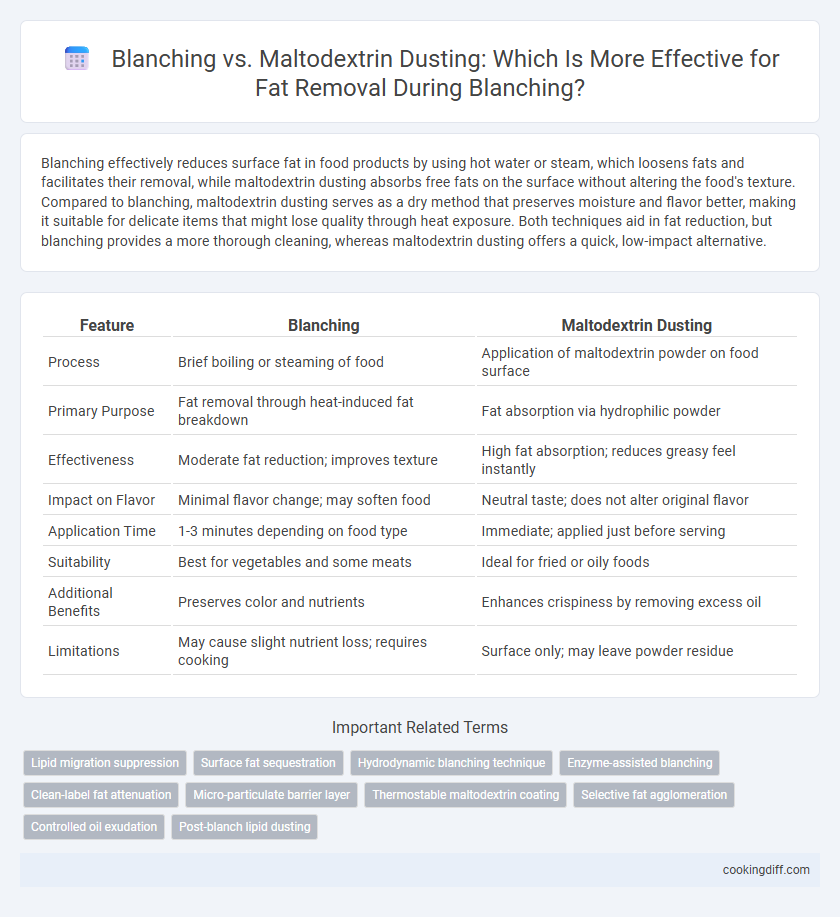

Table of Comparison

| Feature | Blanching | Maltodextrin Dusting |

|---|---|---|

| Process | Brief boiling or steaming of food | Application of maltodextrin powder on food surface |

| Primary Purpose | Fat removal through heat-induced fat breakdown | Fat absorption via hydrophilic powder |

| Effectiveness | Moderate fat reduction; improves texture | High fat absorption; reduces greasy feel instantly |

| Impact on Flavor | Minimal flavor change; may soften food | Neutral taste; does not alter original flavor |

| Application Time | 1-3 minutes depending on food type | Immediate; applied just before serving |

| Suitability | Best for vegetables and some meats | Ideal for fried or oily foods |

| Additional Benefits | Preserves color and nutrients | Enhances crispiness by removing excess oil |

| Limitations | May cause slight nutrient loss; requires cooking | Surface only; may leave powder residue |

Introduction to Fat Removal Techniques in Cooking

Blanching is a cooking technique that uses brief exposure to boiling water or steam to denature enzymes and reduce surface fats in vegetables and meats. Maltodextrin dusting involves applying a fine powder to absorb excess oils, creating a crispy, less greasy texture.

Both methods effectively minimize fat content, enhancing texture and flavor while improving the health profile of dishes. Blanching primarily targets fat removal through heat-induced separation, whereas maltodextrin mechanically absorbs fats from the surface.

Understanding Blanching: Process and Benefits

Blanching involves brief exposure of food products to boiling water or steam to inactivate enzymes and reduce surface contaminants, enhancing fat removal efficiency. Compared to maltodextrin dusting, blanching effectively alters the physical structure of the food, enabling deeper fat extraction.

- Enzyme Inactivation - Blanching halts enzymatic reactions that can degrade food quality and hinder fat removal.

- Surface Cleaning - The process removes dirt, microbes, and surface oils, improving cleanliness before fat extraction.

- Enhanced Fat Extraction - Structural softening from blanching allows better fat release compared to surface-level maltodextrin dusting.

What is Maltodextrin Dusting?

Maltodextrin dusting is a technique used in culinary applications to absorb and remove excess fat from the surface of food. This process involves sprinkling maltodextrin powder, a polysaccharide derived from starch, onto greasy items, which binds with the fat and creates a crumbly texture that can be easily removed.

Unlike blanching, which uses hot water or steam to reduce fat content and preserve texture, maltodextrin dusting specifically targets surface fats without altering the food's moisture or cooking properties. Maltodextrin is preferred for its neutral flavor and high absorption capacity, making it effective for cleaning oils off fried or sauteed foods. This method is particularly useful in professional kitchens seeking to maintain dish presentation and reduce unwanted greasiness quickly.

How Blanching Removes Fat

Blanching removes fat by immersing vegetables or fruits in hot water or steam, which causes the breakdown of cell membranes and releases surface fats and oils. This process effectively reduces the fat content by washing away residual oils without altering the product's natural texture. Unlike maltodextrin dusting, which absorbs fats on the surface, blanching physically removes fat through heat and moisture application.

Fat Absorption Mechanisms of Maltodextrin

Maltodextrin dusting reduces fat absorption by binding free lipids on the food surface, creating a physical barrier that limits oil uptake during cooking. Its polysaccharide structure traps oil molecules, effectively reducing the overall fat content in the final product.

Blanching, in contrast, removes surface oils by water immersion, causing some fat solubilization but not the same lipid-binding effect as maltodextrin. The fat absorption mechanism of maltodextrin is superior as it targets fat retention at a molecular level, enhancing fat reduction more efficiently than blanching alone.

Comparing Efficiency: Blanching vs Maltodextrin Dusting

Which method proves more effective for fat removal: blanching or maltodextrin dusting? Blanching uses hot water or steam to coagulate proteins and release fat, achieving significant fat reduction through thermal treatment. Maltodextrin dusting absorbs surface fat quickly but may be less effective for deep fat removal compared to the thorough fat removal achieved by blanching.

Impact on Food Texture and Flavor

| Method | Impact on Food Texture | Impact on Food Flavor |

|---|---|---|

| Blanching | Softens food by partially cooking, preserving crispness in vegetables but can lead to slight mushiness if overdone. | Maintains natural flavors with minor loss of volatile compounds, resulting in a fresher taste compared to other fat removal methods. |

| Maltodextrin Dusting | Absorbs surface fat without altering core texture, maintaining firmness and crispness in fried or sauteed foods. | Neutral taste profile with slight sweetness, can mask oily flavors without impacting the original food flavor significantly. |

Nutritional Implications of Both Methods

Blanching reduces fat content by using heat to inactivate enzymes and loosen fat particles, which can slightly diminish water-soluble vitamins. Maltodextrin dusting absorbs surface fat without heat, preserving heat-sensitive nutrients but adding carbohydrates. Both methods impact the nutritional profile differently, affecting calorie content and micronutrient retention.

- Blanching reduces fat content - Heat application partially depletes water-soluble vitamins such as vitamin C and B-complex.

- Maltodextrin dusting absorbs fat - This technique retains heat-sensitive nutrients but increases carbohydrate content due to maltodextrin.

- Nutritional trade-offs vary - Blanching lowers fat and some vitamins, maltodextrin maintains vitamins but adds calories from carbohydrates.

Practical Applications in Home and Commercial Kitchens

Blanching effectively reduces surface fat and enzymatic activity in vegetables through brief boiling, making it ideal for batch preparation in commercial kitchens. Maltodextrin dusting absorbs excess oil on fried foods, offering a quick solution for fat removal in both home and professional settings.

- Blanching enhances shelf life - It slows enzymatic browning and texture degradation in vegetables during storage.

- Maltodextrin dusting improves texture - It creates a dry surface on oily foods, enhancing crispiness and presentation.

- Ease of implementation - Blanching requires more equipment and time, whereas maltodextrin dusting is simple and fast for immediate use.

Choosing between blanching and maltodextrin dusting depends on the food type and desired fat removal efficiency.

Related Important Terms

Lipid migration suppression

Blanching effectively suppresses lipid migration by denaturing enzymes and stabilizing cell walls, reducing fat transfer in food processing. Maltodextrin dusting acts as a physical barrier to absorb surface fats but lacks the enzymatic control that blanching provides for comprehensive lipid migration prevention.

Surface fat sequestration

Blanching effectively reduces surface fat by denaturing proteins and disrupting cell membranes, facilitating fat release and removal, whereas maltodextrin dusting sequesters surface fat by absorbing and encapsulating it without altering the food's structure. Surface fat sequestration through blanching enhances downstream processing efficiency, while maltodextrin offers a non-thermal method to control fat presence on food surfaces.

Hydrodynamic blanching technique

Hydrodynamic blanching efficiently removes fat by using high-pressure water jets to dislodge surface oils, outperforming maltodextrin dusting which relies on powder absorption and often leaves residues. This technique enhances fat removal while preserving food texture and nutritional quality, making it a superior method in industrial applications.

Enzyme-assisted blanching

Enzyme-assisted blanching enhances fat removal more effectively than maltodextrin dusting by breaking down lipid structures through targeted enzymatic activity, improving both texture and oil extraction efficiency. This method optimizes the blanching process by reducing residual fat content while preserving nutritive qualities, surpassing the physical absorption capacity of maltodextrin dusting.

Clean-label fat attenuation

Blanching effectively reduces surface fat by coagulating proteins and facilitating fat separation without additives, aligning with clean-label demands for natural processing methods. Maltodextrin dusting absorbs residual oils but introduces an ingredient that may conflict with clean-label preferences despite its efficacy in fat attenuation.

Micro-particulate barrier layer

Blanching creates a micro-particulate barrier layer on food surfaces that effectively reduces fat absorption during frying by altering the texture and surface properties. Maltodextrin dusting forms a physical powdery barrier but is less efficient than blanching in creating a uniform micro-particulate layer that impedes fat penetration.

Thermostable maltodextrin coating

Thermostable maltodextrin coating provides an effective fat removal method by creating a stable barrier that inhibits fat absorption during cooking, outperforming traditional blanching techniques which primarily rely on heat to reduce surface fats. This maltodextrin dusting enhances product texture and shelf-life while maintaining nutritional quality better than blanching, making it a superior option for industrial food processing.

Selective fat agglomeration

Blanching induces selective fat agglomeration by denaturing surface proteins and altering cell structures, which enhances the separation of fat during processing. Maltodextrin dusting, in contrast, adsorbs surface fat physically without modifying the microstructure, resulting in less efficient fat removal compared to the biochemical effects achieved by blanching.

Controlled oil exudation

Blanching effectively controls oil exudation by denaturing surface lipids and enzymes, reducing fat retention during frying, whereas maltodextrin dusting absorbs excess oil but does not limit oil release from within the food matrix. Controlled oil exudation through blanching enhances product crispness and lowers oil uptake, offering a more efficient method for fat reduction compared to surface application methods like maltodextrin dusting.

Blanching vs Maltodextrin dusting for fat removal. Infographic

cookingdiff.com

cookingdiff.com