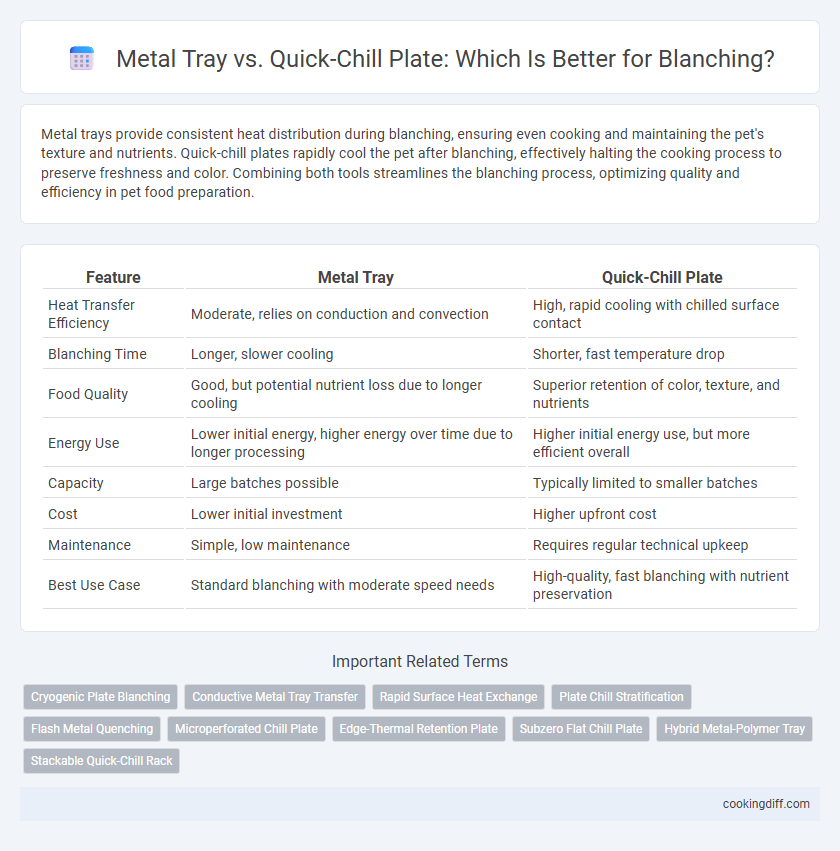

Metal trays provide consistent heat distribution during blanching, ensuring even cooking and maintaining the pet's texture and nutrients. Quick-chill plates rapidly cool the pet after blanching, effectively halting the cooking process to preserve freshness and color. Combining both tools streamlines the blanching process, optimizing quality and efficiency in pet food preparation.

Table of Comparison

| Feature | Metal Tray | Quick-Chill Plate |

|---|---|---|

| Heat Transfer Efficiency | Moderate, relies on conduction and convection | High, rapid cooling with chilled surface contact |

| Blanching Time | Longer, slower cooling | Shorter, fast temperature drop |

| Food Quality | Good, but potential nutrient loss due to longer cooling | Superior retention of color, texture, and nutrients |

| Energy Use | Lower initial energy, higher energy over time due to longer processing | Higher initial energy use, but more efficient overall |

| Capacity | Large batches possible | Typically limited to smaller batches |

| Cost | Lower initial investment | Higher upfront cost |

| Maintenance | Simple, low maintenance | Requires regular technical upkeep |

| Best Use Case | Standard blanching with moderate speed needs | High-quality, fast blanching with nutrient preservation |

Introduction to Blanching and Cooling Methods

| Blanching involves briefly boiling vegetables or fruits followed by rapid cooling to preserve color, texture, and nutrients. Metal trays offer basic cooling by conduction but are less effective in rapidly reducing temperature compared to quick-chill plates, which utilize enhanced surface contact and thermal conductivity for efficient heat dissipation. Quick-chill plates improve process control and reduce cooling time, minimizing enzymatic activity and microbial growth during post-blanching handling. |

What is a Metal Tray in Blanching?

A metal tray in blanching is a flat, heat-conductive surface used to hold vegetables during the steam or hot water treatment process. It allows for even heat distribution but may result in slower cooling compared to quick-chill plates.

- Durability - Metal trays are made from stainless steel or aluminum, providing high resistance to corrosion and repeated use.

- Heat Conductivity - Metal trays efficiently transfer heat to blanching materials, ensuring uniform cooking.

- Cooling Efficiency - Unlike quick-chill plates, metal trays do not actively cool foods, requiring separate cooling steps after blanching.

Understanding Quick-Chill Plates for Blanching

Quick-chill plates provide rapid cooling for blanched vegetables, enhancing texture and preserving nutritional value better than traditional metal trays. These plates use chilled liquid circulated through a metal surface, enabling efficient heat transfer and reducing cooling time significantly.

Unlike metal trays, quick-chill plates maintain consistent temperatures across the food surface, minimizing the risk of overcooking or microbial growth. Their design supports higher throughput in commercial blanching operations by accelerating the cooling phase. This technology improves product quality while optimizing energy consumption and processing efficiency.

Temperature Control: Metal Tray vs Quick-Chill Plate

Metal trays often exhibit uneven temperature distribution during blanching, leading to inconsistent heat exposure. Quick-chill plates provide superior temperature control by rapidly stabilizing the product's temperature.

- Metal Tray Heat Retention - Metal trays retain heat unevenly, causing potential over- or under-blanching in different areas.

- Quick-Chill Plate Efficiency - Quick-chill plates quickly absorb and dissipate heat, maintaining a consistent blanching temperature.

- Temperature Consistency - Quick-chill plates ensure uniform temperature control, reducing quality variability in blanched products.

Quick-chill plates are generally preferred for precise temperature regulation in blanching processes.

Efficiency and Speed of Cooling

Quick-chill plates provide faster cooling rates compared to traditional metal trays, significantly enhancing blanching efficiency by reducing temperature recovery times. This accelerated cooling preserves product quality and extends shelf life more effectively than metal trays.

- Thermal Conductivity - Quick-chill plates use materials with higher thermal conductivity, enabling rapid heat transfer away from the blanched product.

- Cooling Uniformity - Quick-chill plates offer more consistent cooling across the product surface, reducing hot spots common with metal trays.

- Process Throughput - Faster cooling with quick-chill plates increases overall blanching throughput, optimizing production speed and energy use.

Impact on Food Texture and Quality

Metal trays provide even heat distribution during blanching, which helps maintain the firmness and color of vegetables. This uniform heat exposure minimizes texture degradation, preserving the natural crispness of the food.

Quick-chill plates rapidly reduce the temperature post-blanching, preventing overcooking and nutrient loss. This rapid cooling process enhances the overall texture and quality by locking in freshness and reducing cellular damage.

Ease of Use and Handling

Metal trays offer straightforward handling with a simple, flat surface ideal for evenly spreading vegetables during blanching. They are lightweight and durable, making them easy to maneuver and clean after use.

Quick-chill plates provide enhanced temperature control and quicker cooling but often require careful handling due to their heavier construction and integrated cooling mechanisms. Their complexity can make cleaning and maintenance more challenging compared to metal trays.

Cleaning and Maintenance Comparison

Which option offers easier cleaning and maintenance for blanching, a metal tray or a quick-chill plate? Metal trays typically require manual scrubbing to remove food residues, making maintenance more labor-intensive. Quick-chill plates, with their flat surfaces and antimicrobial coatings, allow for faster cleaning and reduced bacterial buildup, enhancing overall hygiene efficiency.

Cost Considerations: Metal Tray vs Quick-Chill Plate

Metal trays offer a lower initial investment for blanching processes compared to quick-chill plates, making them cost-effective for small-scale operations. Quick-chill plates demand higher upfront costs but provide energy-efficient rapid cooling that reduces processing time and operational expenses over time. Evaluating long-term savings versus upfront expenses is crucial when choosing between metal trays and quick-chill plates for blanching applications.

Related Important Terms

Cryogenic Plate Blanching

Cryogenic plate blanching uses metal trays combined with quick-chill plates to enhance heat transfer efficiency, significantly reducing blanching time and preserving nutrient quality. This method leverages the superior thermal conductivity of cryogenic plates, ensuring uniform temperature distribution and minimizing enzymatic activity that causes food degradation.

Conductive Metal Tray Transfer

Metal trays offer superior thermal conductivity for blanching, enabling efficient and uniform heat transfer that maintains vegetable texture and color. Quick-chill plates, while effective for rapid cooling, may lack the consistent thermal conductivity required for optimal blanching, potentially leading to uneven heat distribution and compromised product quality.

Rapid Surface Heat Exchange

Quick-chill plates provide superior rapid surface heat exchange during blanching by ensuring uniform and immediate cooling, significantly reducing enzyme activity and nutrient loss compared to metal trays. Metal trays exhibit slower heat transfer rates, which can lead to uneven blanching and diminished product quality.

Plate Chill Stratification

Quick-chill plates in blanching systems reduce plate chill stratification by providing uniform and rapid heat transfer, minimizing temperature gradients compared to metal trays. Metal trays often exhibit uneven cooling due to slower thermal conductivity and inconsistent contact, resulting in less effective blanching and texture preservation.

Flash Metal Quenching

Flash metal quenching using quick-chill plates offers superior thermal conductivity compared to traditional metal trays, enabling rapid temperature reduction that preserves texture and color during blanching. Quick-chill plates ensure uniform cooling rates, minimizing enzymatic activity and nutrient loss more effectively than conventional metal trays.

Microperforated Chill Plate

Microperforated chill plates offer superior heat transfer efficiency during blanching by enabling rapid cooling and uniform temperature distribution, reducing cooking time and preserving vegetable texture and nutrients better than traditional metal trays. The microperforations enhance water flow and contact, minimizing thermal resistance and ensuring consistent blanching performance critical for high-throughput food processing operations.

Edge-Thermal Retention Plate

Edge-Thermal Retention Plates in blanching offer superior heat distribution and retention compared to traditional metal trays, enabling more consistent temperature control and reducing thermal loss during the blanching process. This optimized thermal efficiency enhances blanching uniformity and productivity, making Edge-Thermal Retention Plates a preferred choice for high-throughput food processing operations.

Subzero Flat Chill Plate

The Subzero Flat Chill Plate offers superior heat transfer efficiency and uniform temperature distribution compared to traditional metal trays, significantly reducing blanching time and preserving vegetable nutrients. Its rapid cooling capability enhances texture retention and minimizes enzymatic activity, making it ideal for high-quality blanching processes.

Hybrid Metal-Polymer Tray

Hybrid metal-polymer trays combine the superior thermal conductivity of metals with the lightweight, corrosion-resistant properties of polymers, enhancing blanching efficiency by ensuring rapid and uniform heat transfer. This innovative hybrid design outperforms traditional metal trays and quick-chill plates by reducing blanching time and minimizing nutrient loss in vegetables.

Metal Tray vs Quick-Chill Plate for blanching. Infographic

cookingdiff.com

cookingdiff.com