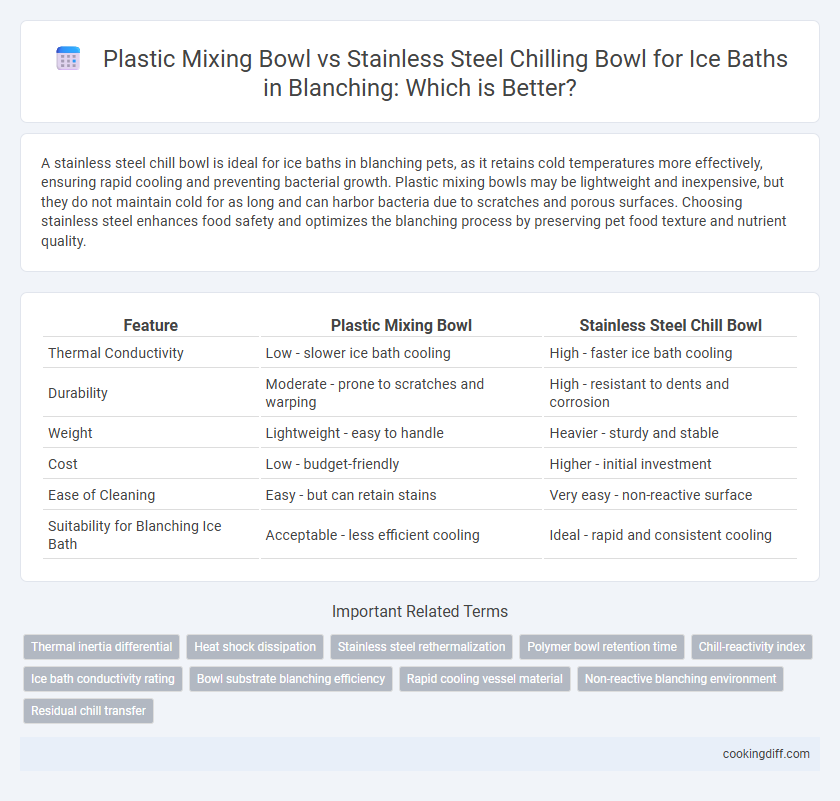

A stainless steel chill bowl is ideal for ice baths in blanching pets, as it retains cold temperatures more effectively, ensuring rapid cooling and preventing bacterial growth. Plastic mixing bowls may be lightweight and inexpensive, but they do not maintain cold for as long and can harbor bacteria due to scratches and porous surfaces. Choosing stainless steel enhances food safety and optimizes the blanching process by preserving pet food texture and nutrient quality.

Table of Comparison

| Feature | Plastic Mixing Bowl | Stainless Steel Chill Bowl |

|---|---|---|

| Thermal Conductivity | Low - slower ice bath cooling | High - faster ice bath cooling |

| Durability | Moderate - prone to scratches and warping | High - resistant to dents and corrosion |

| Weight | Lightweight - easy to handle | Heavier - sturdy and stable |

| Cost | Low - budget-friendly | Higher - initial investment |

| Ease of Cleaning | Easy - but can retain stains | Very easy - non-reactive surface |

| Suitability for Blanching Ice Bath | Acceptable - less efficient cooling | Ideal - rapid and consistent cooling |

Understanding the Role of Ice Baths in Blanching

Using a stainless steel chill bowl for an ice bath during blanching offers superior thermal conductivity, ensuring rapid cooling that stops the cooking process effectively and preserves vegetable texture and color. Plastic mixing bowls retain heat longer, which may slow the cooling rate and affect the quality of the blanched produce. The optimal ice bath setup prioritizes temperature control, making stainless steel bowls the preferred choice for efficient heat transfer and food safety in blanching.

Why Choose the Right Bowl for Ice Baths?

Why is choosing the right bowl for ice baths important in blanching? Stainless steel chill bowls provide superior thermal conductivity, ensuring faster and more efficient cooling of vegetables. Plastic mixing bowls, while lightweight, lack the same heat transfer capabilities, potentially prolonging the cooling process and compromising food quality.

Overview: Plastic Mixing Bowls for Ice Baths

| Material | Plastic |

|---|---|

| Thermal Conductivity | Low, retains cold slower than stainless steel |

| Weight | Lightweight, easy to handle during blanching |

| Durability | Resistant to dents and corrosion, but prone to scratches and stains |

| Cost | Generally lower priced compared to stainless steel bowls |

| Suitability for Ice Baths | Suitable for short-term ice baths, less effective for prolonged chilling due to insulating properties |

Overview: Stainless Steel Chill Bowls for Ice Baths

Stainless steel chill bowls excel in maintaining low temperatures during ice baths due to their superior thermal conductivity and durability compared to plastic mixing bowls. Their non-porous surface prevents bacterial growth, ensuring a hygienic environment for blanching vegetables.

Unlike plastic bowls, stainless steel chill bowls resist chemical stains and odors, making them ideal for repeated use in food preparation. Their sturdy construction allows efficient temperature retention, which is crucial for rapidly cooling vegetables and preserving texture and color.

Temperature Retention: Plastic vs Stainless Steel

Stainless steel bowls retain cold temperatures more effectively than plastic bowls, enhancing ice bath efficiency during blanching. Plastic bowls warm faster, reducing the duration and effectiveness of the ice bath.

- Stainless steel conductivity - Stainless steel's high thermal conductivity helps maintain lower water temperatures in ice baths longer than plastic.

- Plastic insulation - Plastic acts as an insulator, causing ice water to warm quicker and diminishing the blanching process.

- Durability and reuse - Stainless steel bowls withstand repeated temperature shocks better, ensuring consistent performance during multiple blanching sessions.

Safety and Durability Considerations

Stainless steel chill bowls offer superior durability and resistance to cracking under extreme cold temperatures compared to plastic mixing bowls. Safety is enhanced with stainless steel as it does not leach chemicals when exposed to ice bath conditions, making it a healthier choice for food preparation.

- Durability - Stainless steel bowls withstand thermal shock and physical impact better than plastic.

- Safety - Unlike some plastics, stainless steel is non-reactive and prevents chemical contamination.

- Longevity - Stainless steel bowls maintain integrity and appearance with repeated use in ice baths.

Choosing a stainless steel chill bowl ensures reliable performance and safer handling during the blanching ice bath process.

Ease of Handling and Cleaning

Plastic mixing bowls are lightweight and easier to handle during blanching, making them convenient for quick ice baths. Their non-porous surface usually simplifies cleaning by resisting stains and odors better than some metals.

Stainless steel chill bowls offer superior durability and maintain cold temperatures longer, which is beneficial for efficient ice baths. However, their heavier weight can make handling cumbersome, especially when full of water and ice. Cleaning stainless steel requires more effort to avoid water spots and maintain a polished finish, but they are dishwasher safe and highly resistant to corrosion.

Impact on Food Quality and Blanching Results

Stainless steel chill bowls maintain consistent cold temperatures better than plastic mixing bowls, ensuring rapid cooling during blanching and preserving the food's vibrant color and crisp texture. Plastic bowls tend to retain heat, which can slow the ice bath effect, leading to less effective blanching and potential nutrient loss.

The superior thermal conductivity of stainless steel promotes immediate cooling, preventing overcooking and preserving vitamins such as Vitamin C and folate in vegetables. Plastic bowls may cause uneven cooling, resulting in a diminished final product quality and compromised blanching results.

Cost Comparison: Plastic vs Stainless Steel Bowls

Plastic mixing bowls typically cost significantly less than stainless steel chill bowls, making them a budget-friendly option for ice baths during blanching. Stainless steel bowls, although more expensive upfront, offer superior durability, resistance to staining, and longer lifespan, which may reduce replacement costs over time. Choosing between plastic and stainless steel involves balancing initial investment with long-term use and performance in blanched food preparation.

Related Important Terms

Thermal inertia differential

Plastic mixing bowls have higher thermal inertia due to lower thermal conductivity, causing slower heat transfer during an ice bath, which can delay the cooling process in blanching. Stainless steel chill bowls, with lower thermal inertia and higher thermal conductivity, rapidly absorb and dissipate heat, making them more efficient for quick temperature reduction in ice baths.

Heat shock dissipation

Plastic mixing bowls have lower thermal conductivity than stainless steel chill bowls, resulting in slower heat shock dissipation during ice baths. Stainless steel bowls rapidly absorb and transfer cold temperatures, minimizing temperature fluctuations and improving the blanching process by quickly halting enzyme activity.

Stainless steel rethermalization

Stainless steel chill bowls offer superior thermal conductivity and durability compared to plastic mixing bowls, enabling faster and more efficient rethermalization during blanching ice baths. Their non-porous surface and resistance to temperature shock ensure optimal cooling performance and longer lifespan in professional kitchen environments.

Polymer bowl retention time

Polymer mixing bowls used in blanching processes typically exhibit longer retention times due to lower thermal conductivity, which slows ice bath cooling compared to stainless steel chill bowls that rapidly dissipate heat for faster cooling. This characteristic affects blanching efficiency, making stainless steel bowls preferable for precise temperature control and minimizing nutrient loss during ice bath treatment.

Chill-reactivity index

Stainless steel bowls have a lower chill-reactivity index compared to plastic mixing bowls, making them more effective for maintaining rapid, even cooling during an ice bath in blanching. This reduced reactivity minimizes temperature fluctuations and preserves vegetable texture and color more consistently.

Ice bath conductivity rating

Stainless steel chill bowls exhibit higher thermal conductivity rates, rapidly transferring cold temperatures during an ice bath, which effectively halts the blanching process and preserves vegetable texture and color. In contrast, plastic mixing bowls have lower thermal conductivity, leading to slower cooling and less efficient heat transfer, potentially compromising the speed and effectiveness of the ice bath.

Bowl substrate blanching efficiency

Stainless steel chill bowls offer superior thermal conductivity compared to plastic mixing bowls, enabling faster and more efficient heat transfer during ice bath blanching processes. This enhanced cooling efficiency reduces blanching time and minimizes enzymatic activity, preserving vegetable texture and color more effectively.

Rapid cooling vessel material

Stainless steel chill bowls offer superior thermal conductivity compared to plastic mixing bowls, enabling faster ice bath cooling of blanching vegetables and preserving their color and texture. The higher heat transfer efficiency of stainless steel reduces cooling time, minimizing nutrient loss and ensuring optimal food quality.

Non-reactive blanching environment

Stainless steel chill bowls provide a non-reactive blanching environment ideal for ice baths, preserving food flavor and preventing chemical reactions often caused by plastic mixing bowls. The durable, metal surface of stainless steel resists staining and absorbs less heat, ensuring rapid cooling and maintaining optimal food safety standards.

Plastic mixing bowl vs stainless chill bowl for ice bath. Infographic

cookingdiff.com

cookingdiff.com