Blanching involves briefly heating fruit to inactivate enzymes and preserve color and texture, while acidulated blanching incorporates an acid, such as lemon juice or citric acid, to further inhibit enzymatic browning and microbial growth. Acidulated blanching enhances the preservation of fruit quality and extends shelf life more effectively than plain blanching. This method is particularly beneficial for light-colored fruits prone to discoloration during processing.

Table of Comparison

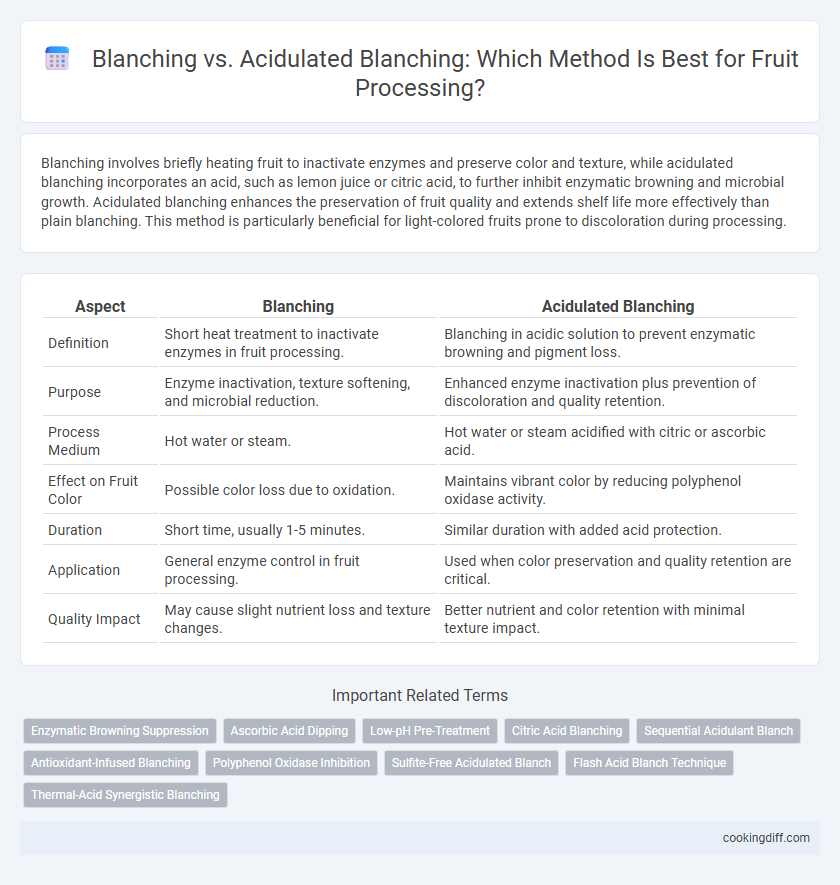

| Aspect | Blanching | Acidulated Blanching |

|---|---|---|

| Definition | Short heat treatment to inactivate enzymes in fruit processing. | Blanching in acidic solution to prevent enzymatic browning and pigment loss. |

| Purpose | Enzyme inactivation, texture softening, and microbial reduction. | Enhanced enzyme inactivation plus prevention of discoloration and quality retention. |

| Process Medium | Hot water or steam. | Hot water or steam acidified with citric or ascorbic acid. |

| Effect on Fruit Color | Possible color loss due to oxidation. | Maintains vibrant color by reducing polyphenol oxidase activity. |

| Duration | Short time, usually 1-5 minutes. | Similar duration with added acid protection. |

| Application | General enzyme control in fruit processing. | Used when color preservation and quality retention are critical. |

| Quality Impact | May cause slight nutrient loss and texture changes. | Better nutrient and color retention with minimal texture impact. |

Introduction to Blanching in Fruit Processing

Blanching is a critical pre-treatment step in fruit processing that involves briefly exposing fruits to boiling water or steam to inactivate enzymes and preserve quality. Acidulated blanching incorporates acidic agents, such as citric acid, during the blanching process to enhance color retention and reduce enzymatic browning.

- Conventional blanching - Primarily focuses on enzyme inactivation and microbial reduction through heat treatment.

- Acidulated blanching - Utilizes acidic solutions to maintain natural fruit color and improve shelf life.

- Impact on texture - Both methods affect fruit firmness differently depending on treatment intensity and fruit type.

What Is Acidulated Blanching?

| Acidulated blanching is a fruit processing method where fruits are briefly dipped in boiling water containing acidulants like citric acid or lemon juice before cooling. This technique helps inhibit enzymatic browning and preserve color, flavor, and nutritional quality more effectively than plain blanching. Commonly used in apple and peach processing, acidulated blanching enhances shelf life and maintains the fruit's sensory attributes during storage. |

Key Differences Between Standard and Acidulated Blanching

Blanching is a heat treatment process used to inactivate enzymes in fruits, preserving color and texture during storage. Acidulated blanching incorporates organic acids like citric acid into the blanching water to further prevent enzymatic browning and microbial growth.

- Enzyme Inactivation - Standard blanching primarily deactivates enzymes such as polyphenol oxidase, while acidulated blanching enhances enzyme inhibition through acid-induced pH reduction.

- Color Preservation - Acidulated blanching better maintains fruit color by minimizing oxidative browning compared to standard blanching.

- Microbial Control - The acidic environment in acidulated blanching offers improved antimicrobial properties versus conventional blanching methods.

Effects on Fruit Color Preservation

Blanching preserves fruit color by inactivating enzymes that cause browning and color degradation, maintaining the vibrant appearance of fruits during processing. Acidulated blanching involves adding acidic agents, such as citric acid, which enhances color preservation by stabilizing anthocyanins and preventing enzymatic browning more effectively than plain blanching. Studies show acidulated blanching results in brighter, more stable fruit colors, crucial for processed products like canned peaches and apples.

Impact on Nutrient Retention

Blanching effectively inactivates enzymes that cause nutrient degradation in fruits, preserving vitamins such as vitamin C and antioxidants. Acidulated blanching, which involves adding acidic agents like lemon juice or citric acid, enhances nutrient retention by stabilizing color and reducing oxidative loss. Studies show acidulated blanching better maintains ascorbic acid levels compared to standard blanching methods during fruit processing.

Influence on Fruit Texture and Firmness

Blanching in fruit processing primarily softens the fruit texture by disrupting cell walls, which reduces firmness and facilitates peeling or further processing. This thermal treatment often leads to a uniform texture but can cause slight nutrient loss.

Acidulated blanching incorporates acidic solutions like lemon juice or citric acid, which help maintain fruit firmness by strengthening pectin structures and minimizing tissue breakdown. The acidic environment slows enzymatic reactions, preserving a crisper texture compared to conventional blanching methods.

Suitability for Different Types of Fruit

Blanching is suitable for fruits with thicker skins and denser flesh, effectively inactivating enzymes without altering flavor significantly. Acidulated blanching is preferable for delicate fruits prone to browning, as the acid helps maintain color and texture during processing.

- Blanching - Ideal for fruits like apples and pears that require enzyme inactivation without affecting taste.

- Acidulated Blanching - Best for berries and peaches where color retention and texture preservation are critical.

- Fruit Type Sensitivity - Acidulated blanching reduces browning in fruits sensitive to oxidation compared to standard blanching.

Choosing the appropriate blanching method depends on the fruit's texture, skin thickness, and susceptibility to enzymatic browning.

Process Steps: Blanching vs Acidulated Blanching

How do the process steps of blanching differ from acidulated blanching in fruit processing? Blanching involves briefly boiling fruits to inactivate enzymes and soften tissue, followed by immediate cooling in cold water. Acidulated blanching incorporates an acidic solution, like lemon juice or citric acid, during blanching to better preserve color and prevent enzymatic browning.

Applications in Commercial Fruit Processing

Blanching in commercial fruit processing involves briefly exposing fruits to hot water or steam to inactivate enzymes, preserving color, texture, and nutritional value. Acidulated blanching integrates organic acids such as citric or ascorbic acid to further prevent enzymatic browning and extend shelf life.

Standard blanching is commonly applied to fruits like peaches and apricots to soften texture and reduce microbial load before freezing or canning. Acidulated blanching is preferred for fruits prone to oxidation, including apples and pears, enhancing quality during storage and processing.

Related Important Terms

Enzymatic Browning Suppression

Blanching effectively inactivates polyphenol oxidase enzymes responsible for enzymatic browning in fruit processing, but acidulated blanching, which involves adding acids like citric acid, enhances this suppression by lowering pH and preventing browning more efficiently. The combination of thermal treatment and acidification ensures optimal color retention and quality in processed fruits.

Ascorbic Acid Dipping

Ascorbic acid dipping during acidulated blanching effectively minimizes enzymatic browning and preserves the vitamin C content in fruits better than traditional blanching alone. This method enhances color retention, texture, and nutritional quality by reducing oxidative degradation and preventing polyphenol oxidase activity.

Low-pH Pre-Treatment

Blanching in fruit processing effectively inactivates enzymes and preserves texture, while acidulated blanching incorporates low-pH pre-treatment to enhance color retention and inhibit enzymatic browning more efficiently. Low-pH pre-treatment with acidulated solutions like citric acid or ascorbic acid lowers the pH, improving antioxidant activity and extending shelf life by reducing microbial growth and oxidative damage.

Citric Acid Blanching

Citric acid blanching enhances fruit color retention, texture, and microbial stability by lowering pH and reducing enzymatic browning, outperforming traditional hot water blanching. This method extends shelf life and preserves nutritional quality, making it ideal for fruits like apples, peaches, and pears in commercial processing.

Sequential Acidulant Blanch

Sequential Acidulant Blanch involves initially blanching fruit in hot water followed by immersion in an acidulated solution, enhancing enzyme inactivation and microbial control compared to standard blanching. This method improves color retention, texture, and nutrient preservation by reducing oxidative browning and prolonging shelf life in fruit processing.

Antioxidant-Infused Blanching

Blanching preserves fruit quality by deactivating oxidative enzymes, while acidulated blanching, using acidic solutions like citric acid, enhances antioxidant retention and inhibits enzymatic browning more effectively. Antioxidant-infused blanching integrates natural antioxidants such as ascorbic acid or green tea extract during the process, significantly improving the fruit's nutritional value and shelf life by reducing oxidative degradation.

Polyphenol Oxidase Inhibition

Blanching effectively inhibits polyphenol oxidase (PPO) activity by denaturing the enzyme through heat, thus preventing enzymatic browning in fruit processing. Acidulated blanching enhances PPO inhibition by maintaining a low pH environment, which further reduces enzyme activity and improves color retention in treated fruits.

Sulfite-Free Acidulated Blanch

Sulfite-free acidulated blanching in fruit processing uses natural acids such as citric or ascorbic acid to prevent enzymatic browning and microbial growth while maintaining fruit quality, color, and nutritional value better than traditional sulfite-based blanching. This method is preferred for producing allergen-free, clean-label fruit products, ensuring compliance with organic standards and reducing potential sulfite-related health risks.

Flash Acid Blanch Technique

Flash acid blanching preserves fruit color, texture, and nutritional value more effectively than traditional blanching by using a brief immersion in acidulated hot water or steam. This technique minimizes enzymatic browning and microbial growth, enhancing shelf life and quality in fruit processing.

Blanching vs Acidulated Blanching for fruit processing Infographic

cookingdiff.com

cookingdiff.com