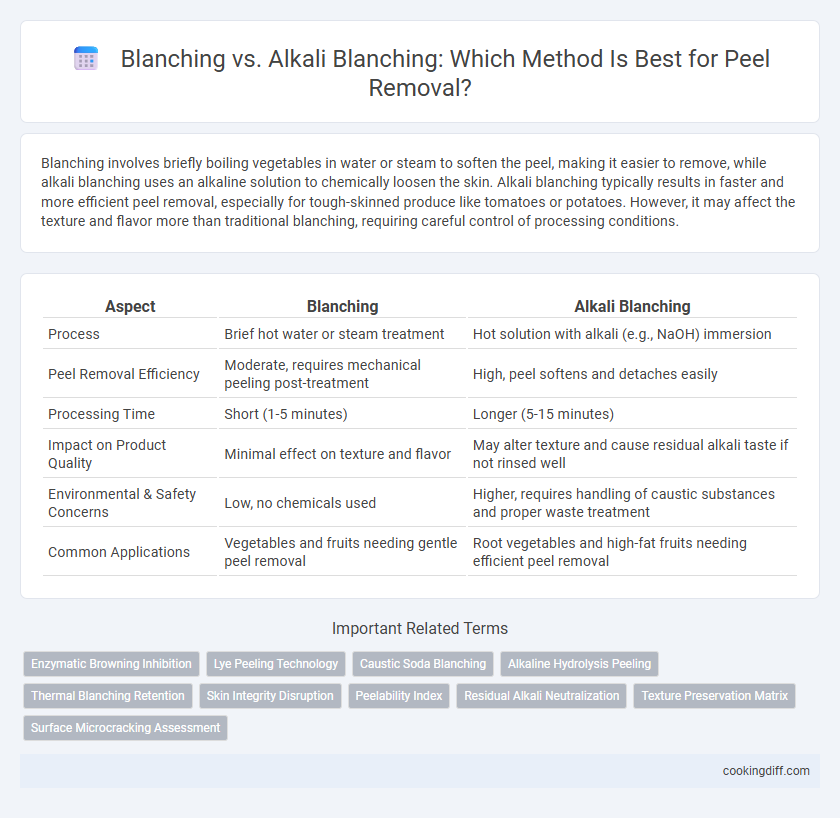

Blanching involves briefly boiling vegetables in water or steam to soften the peel, making it easier to remove, while alkali blanching uses an alkaline solution to chemically loosen the skin. Alkali blanching typically results in faster and more efficient peel removal, especially for tough-skinned produce like tomatoes or potatoes. However, it may affect the texture and flavor more than traditional blanching, requiring careful control of processing conditions.

Table of Comparison

| Aspect | Blanching | Alkali Blanching |

|---|---|---|

| Process | Brief hot water or steam treatment | Hot solution with alkali (e.g., NaOH) immersion |

| Peel Removal Efficiency | Moderate, requires mechanical peeling post-treatment | High, peel softens and detaches easily |

| Processing Time | Short (1-5 minutes) | Longer (5-15 minutes) |

| Impact on Product Quality | Minimal effect on texture and flavor | May alter texture and cause residual alkali taste if not rinsed well |

| Environmental & Safety Concerns | Low, no chemicals used | Higher, requires handling of caustic substances and proper waste treatment |

| Common Applications | Vegetables and fruits needing gentle peel removal | Root vegetables and high-fat fruits needing efficient peel removal |

Understanding Traditional Blanching for Peel Removal

Traditional blanching involves briefly immersing fruits or vegetables in boiling water or steam to loosen the peel for easier removal. This method primarily relies on heat to soften the outer layer, preserving the texture and color of the produce.

Understanding traditional blanching reveals it as a gentle process compared to alkali blanching, which uses a chemical solution to break down peel structure more aggressively. While alkali blanching can expedite peel removal, it may alter the nutritional content and flavor of the food. Traditional blanching is preferred for preserving natural qualities while still facilitating efficient peel removal.

What Is Alkali Blanching?

Alkali blanching involves treating vegetables or fruits with a mild alkaline solution, such as sodium hydroxide, to loosen or soften the peel for easier removal. This method accelerates peel removal by breaking down pectin and cell walls more effectively than traditional hot water blanching. Alkali blanching is commonly used in processing crops like tomatoes and peaches to enhance peeling efficiency and product quality.

Key Differences Between Blanching and Alkali Blanching

What are the key differences between blanching and alkali blanching for peel removal? Blanching uses hot water or steam to loosen peels, preserving texture and nutrients with minimal chemical alteration. Alkali blanching involves soaking produce in alkaline solutions, accelerating peel removal but potentially affecting taste and nutritional content.

Effectiveness in Removing Peels

Blanching uses hot water or steam to soften peels, making them easier to remove, but it may not fully loosen tougher skins. Alkali blanching, involving mild alkaline solutions like sodium bicarbonate, enhances peel removal by breaking down cell walls and loosening the peel more effectively.

Alkali blanching accelerates the peeling process, especially for fibrous fruits and vegetables, resulting in higher peel removal efficiency and reduced processing time. However, proper control of alkali concentration and blanching time is essential to avoid texture and flavor degradation.

Impact on Nutrient Retention

Blanching effectively softens fruit and vegetable skins, facilitating peel removal while moderately preserving water-soluble vitamins like vitamin C. Alkali blanching enhances peel removal efficiency but may cause greater nutrient loss due to the higher pH accelerating degradation of sensitive compounds. Studies show standard blanching better retains antioxidants and phenolic content compared to alkali blanching, making it preferable when nutrient retention is a priority.

Influence on Flavor and Texture

Blanching preserves the natural flavor and crisp texture of vegetables by gently heating, which helps maintain cellular integrity. This method prevents the development of off-flavors and promotes a consistent taste profile ideal for fresh produce.

Alkali blanching, involving a mild alkaline solution, can enhance peel removal but may alter flavor by introducing a slightly bitter or soapy taste. The texture often becomes softer and less crisp due to the chemical breakdown of pectin and cell walls during the process.

Food Safety Considerations

Blanching effectively reduces microbial load and enzymatic activity, ensuring safer peel removal without introducing harmful residues. Alkali blanching enhances peel separation but may pose risks due to chemical residues and altered pH that require thorough washing for food safety compliance.

- Microbial Reduction - Traditional blanching uses heat to significantly lower bacterial and fungal presence on produce surfaces.

- Chemical Residue Risks - Alkali blanching can leave sodium hydroxide residues that demand stringent rinsing protocols.

- pH Impact - Alkali treatments can increase surface pH, potentially affecting microbial survival and consumer safety if not properly controlled.

Environmental and Health Implications

Blanching uses hot water or steam, minimizing chemical waste and environmental pollution, making it a safer option for peel removal. Alkali blanching involves chemicals like sodium hydroxide, which can generate harmful effluents, posing health risks to workers and requiring careful waste management.

- Lower Environmental Impact - Traditional blanching produces biodegradable waste with minimal toxicity compared to the alkaline residues from alkali blanching.

- Worker Safety - Chemical exposure in alkali blanching increases risks of skin irritation and respiratory issues absent in conventional blanching.

- Waste Management - Alkali blanching necessitates advanced effluent treatment to neutralize hazardous byproducts, unlike simpler water disposal in blanching.

Culinary Applications: When to Use Each Method

Blanching is ideal for delicate fruits and vegetables where mild heat treatment preserves texture and color, while alkali blanching is preferred for tougher skins requiring more intensive peel removal. Culinary applications dictate the choice based on the type of produce and desired final texture.

- Blanching - Uses hot water or steam to loosen skins without altering flavor significantly.

- Alkali Blanching - Involves a dilute alkaline solution to break down tougher skins rapidly.

- Food Texture - Blanching is best for maintaining crispness, alkali blanching softens produce extensively.

Choosing between blanching and alkali blanching enhances peel removal efficiency without compromising culinary quality.

Related Important Terms

Enzymatic Browning Inhibition

Blanching effectively inhibits enzymatic browning by denaturing polyphenol oxidase enzymes through heat, while alkali blanching enhances peel removal by breaking down cell walls but may alter pH, impacting enzyme activity differently. Alkali blanching's elevated pH environment can further suppress enzymatic browning, complementing thermal inactivation and improving peel removal efficiency.

Lye Peeling Technology

Lye peeling technology uses alkali blanching, employing sodium hydroxide solutions to effectively loosen fruit and vegetable peels for easier removal, enhancing peel detachment compared to conventional hot water blanching. This method increases processing efficiency and yield by softening the epidermis without compromising internal texture or nutritional quality.

Caustic Soda Blanching

Caustic soda blanching, a type of alkali blanching, uses sodium hydroxide to rapidly soften fruit or vegetable peels for efficient removal, enhancing processing speed compared to conventional water blanching. This method improves peel separation without compromising product quality, making it ideal for industrial-scale peel removal in citrus and other produce.

Alkaline Hydrolysis Peeling

Alkaline hydrolysis peeling uses a caustic solution to break down cell walls rapidly, offering a more efficient peel removal compared to traditional blanching, which relies on heat to loosen peels. This method enhances peel separation in fruits and vegetables like tomatoes and potatoes, reducing processing time and minimizing nutrient loss.

Thermal Blanching Retention

Thermal blanching preserves higher levels of vitamins and antioxidants in vegetables compared to alkali blanching, which can degrade sensitive nutrients due to its chemical nature. The controlled heat exposure in thermal blanching ensures better retention of color and texture while facilitating efficient peel removal without compromising nutritional quality.

Skin Integrity Disruption

Blanching primarily disrupts skin integrity through heat-induced cell wall softening, facilitating peel removal by weakening the adhesion between the skin and underlying tissues. Alkali blanching, on the other hand, chemically breaks down pectin and hemicellulose in the skin, resulting in more extensive disruption of the epidermal structure and faster, easier peel separation.

Peelability Index

Blanching typically achieves a moderate Peelability Index by softening the peel through heat, while Alkali Blanching significantly increases the Peelability Index by chemically breaking down peel adhesion, enhancing ease of peel removal. Studies indicate that Alkali Blanching can improve peel removal efficiency by up to 30% compared to conventional thermal blanching methods.

Residual Alkali Neutralization

Blanching with alkali involves using alkaline solutions to loosen fruit or vegetable peels, but residual alkali must be neutralized to prevent adverse effects on taste and texture. Neutralization typically involves rinsing with acidified water or applying a mild acid treatment to ensure complete removal of alkali residues, preserving product quality.

Texture Preservation Matrix

Blanching preserves texture by softening produce with hot water or steam, maintaining firmness and cell structure, while alkali blanching, which uses alkaline solutions, can lead to excessive softening and potential cell wall degradation, compromising texture integrity. The texture preservation matrix favors conventional blanching methods for maintaining optimal crispness and structural quality during peel removal.

Blanching vs Alkali Blanching for peel removal. Infographic

cookingdiff.com

cookingdiff.com