Blanching involves briefly boiling produce in water or steam to inactivate enzymes and preserve color, texture, and flavor, while dry blanching uses hot air or steam without immersion, reducing water absorption and nutrient loss. Dry blanching offers better retention of water-soluble vitamins and improved texture compared to traditional wet blanching, which may cause nutrient leaching. Choosing between blanching and dry blanching depends on the type of produce and desired quality outcomes for storage or cooking.

Table of Comparison

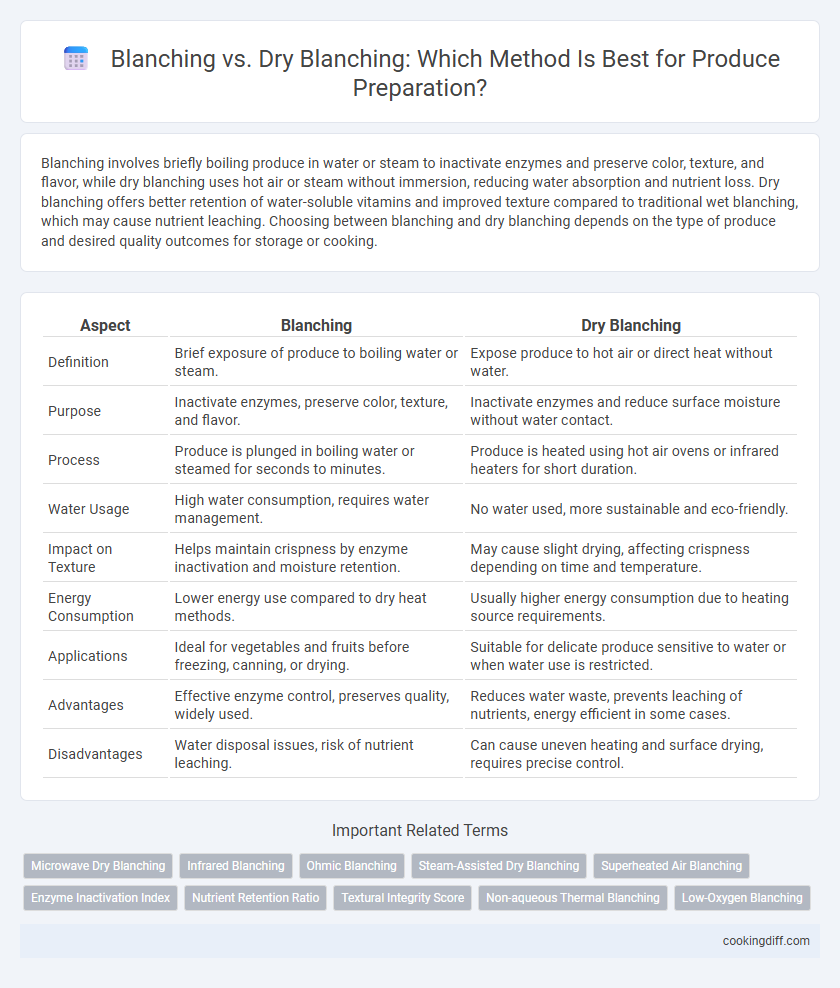

| Aspect | Blanching | Dry Blanching |

|---|---|---|

| Definition | Brief exposure of produce to boiling water or steam. | Expose produce to hot air or direct heat without water. |

| Purpose | Inactivate enzymes, preserve color, texture, and flavor. | Inactivate enzymes and reduce surface moisture without water contact. |

| Process | Produce is plunged in boiling water or steamed for seconds to minutes. | Produce is heated using hot air ovens or infrared heaters for short duration. |

| Water Usage | High water consumption, requires water management. | No water used, more sustainable and eco-friendly. |

| Impact on Texture | Helps maintain crispness by enzyme inactivation and moisture retention. | May cause slight drying, affecting crispness depending on time and temperature. |

| Energy Consumption | Lower energy use compared to dry heat methods. | Usually higher energy consumption due to heating source requirements. |

| Applications | Ideal for vegetables and fruits before freezing, canning, or drying. | Suitable for delicate produce sensitive to water or when water use is restricted. |

| Advantages | Effective enzyme control, preserves quality, widely used. | Reduces water waste, prevents leaching of nutrients, energy efficient in some cases. |

| Disadvantages | Water disposal issues, risk of nutrient leaching. | Can cause uneven heating and surface drying, requires precise control. |

Introduction to Blanching and Dry Blanching

Blanching is a heat treatment process where produce is briefly boiled or steamed to inactivate enzymes, preserve color, texture, and nutrients. Dry blanching uses hot air or infrared heat instead of water, minimizing moisture loss and reducing processing time.

- Blanching - Involves submerging produce in boiling water or steam to halt enzymatic activity.

- Dry Blanching - Utilizes hot air or infrared radiation to treat produce without direct water contact.

- Purpose - Both methods aim to enhance shelf life and quality before freezing or further processing.

Choosing between blanching and dry blanching depends on the type of produce and desired processing outcomes.

Understanding Traditional Blanching Methods

Traditional blanching involves briefly boiling produce in water to inactivate enzymes, preserve color, and maintain texture before freezing or cooking. This method helps reduce microbial load and slows spoilage, ensuring extended shelf life and quality retention in fruits and vegetables.

Dry blanching, or steam blanching, uses hot steam instead of water, minimizing nutrient loss and reducing water absorption in the produce. It provides a gentler heat treatment that better preserves vitamins and antioxidants compared to conventional water blanching.

What is Dry Blanching?

| Dry Blanching is a heat treatment process for produce preparation where vegetables or fruits are exposed to hot air or steam without direct contact with boiling water. |

| This method helps inactivating enzymes, reducing microbial load, and preserving texture and nutrients better than traditional wet blanching. |

| Dry blanching is preferred for delicate produce prone to water absorption and nutrient leaching, ensuring improved shelf life and quality retention. |

Key Differences: Blanching vs Dry Blanching

Blanching involves briefly boiling produce in water or steam to inactivate enzymes and preserve color, texture, and nutritional quality, while dry blanching uses hot air or infrared heat instead. Water blanching is more effective for heat-sensitive vegetables, ensuring uniform temperature penetration, whereas dry blanching reduces water loss and nutrient leaching. The choice between blanching and dry blanching depends on the type of produce and desired shelf life, with dry blanching favored for delicate fruits and water blanching for robust vegetables.

Nutrient Retention in Blanching vs Dry Blanching

Blanching involves briefly boiling vegetables, which can cause water-soluble vitamins like vitamin C and B-complex to leach into the water, potentially reducing nutrient retention. Dry blanching, using hot air or steam without water immersion, better preserves these nutrients by minimizing direct contact with water. Studies show dry blanching retains higher levels of antioxidants and vitamins compared to traditional water blanching methods.

Impact on Flavor and Texture

Blanching with hot water preserves the natural flavor and tenderness of produce by slowing enzymatic activity while maintaining moisture content. Dry blanching, using steam or air, can intensify flavors but risks drying out the texture, leading to a firmer, sometimes tougher product.

- Hot Water Blanching Preserves Moisture - This method retains juiciness and prevents flavor loss by quickly heating the produce in water.

- Dry Blanching Enhances Flavor Intensity - Steam or air exposure concentrates flavors but may reduce moisture, affecting texture.

- Texture Differences Influence Culinary Use - Moisture preservation in wet blanching results in softer produce ideal for salads, while dry blanching yields firmer textures suited for roasting or sauteing.

Best Produce Types for Blanching and Dry Blanching

Blanching is ideal for vegetables with dense textures such as green beans, broccoli, and carrots, as it helps preserve color, flavor, and nutritional value while softening the produce. Dry blanching, which uses hot air instead of water, is best suited for delicate items like leafy greens and mushrooms to reduce moisture loss and maintain crispness.

Root vegetables and legumes benefit most from traditional water blanching due to their firm structure requiring thorough heat penetration. In contrast, dry blanching is preferred for produce sensitive to water absorption, such as asparagus and bell peppers, to prevent sogginess and maintain texture.

Equipment and Safety Tips

Blanching equipment typically includes hot water baths or steam blanchers designed for controlled temperature and time exposure, ensuring uniform heat treatment of produce. In contrast, dry blanching uses heated air or infrared systems that require precise control to prevent scorching or uneven processing.

When selecting equipment, focus on models with adjustable temperature settings and reliable timers to minimize nutrient loss and optimize texture. For dry blanching, ensure proper ventilation to avoid heat buildup and potential fire hazards. Always wear heat-resistant gloves and follow manufacturer guidelines to maintain worker safety during both blanching methods.

Efficiency and Time Considerations

Which method between blanching and dry blanching offers greater efficiency for produce preparation? Blanching uses hot water or steam to quickly soften produce, making it faster but requiring more energy and water. Dry blanching, involving heat without water, conserves resources but generally demands more time to achieve similar results.

Related Important Terms

Microwave Dry Blanching

Microwave dry blanching offers a rapid, energy-efficient alternative to traditional wet blanching by using microwave radiation to inactivate enzymes in produce without water, preserving nutrients and texture more effectively. This method reduces nutrient leaching, minimizes processing time, and enhances shelf life, making it ideal for high-quality vegetable preparation.

Infrared Blanching

Infrared blanching uses infrared radiation to rapidly heat the surface of produce, preserving nutrients and flavor better than traditional wet blanching, which relies on hot water or steam. This method reduces water usage, minimizes nutrient leaching, and enhances texture retention compared to dry blanching techniques that may cause uneven heating or product desiccation.

Ohmic Blanching

Ohmic blanching uses electrical currents to heat produce rapidly and uniformly, preserving nutrients and texture better than traditional dry blanching methods. This technique enhances energy efficiency, reduces processing time, and minimizes water usage, making it ideal for high-quality produce preparation.

Steam-Assisted Dry Blanching

Steam-assisted dry blanching combines the benefits of conventional blanching and dry blanching by using steam to heat produce while minimizing water contact, preserving nutrients and texture more effectively than traditional water blanching. This method reduces nutrient leaching and oxidation, enhances color retention, and improves shelf life compared to standard dry blanching techniques.

Superheated Air Blanching

Superheated air blanching uses heated air above 100degC to effectively inactivate enzymes in produce without water contact, preserving nutrient quality and texture better than traditional water blanching. This dry blanching method reduces water usage and waste while minimizing nutrient leaching and enhancing shelf life for fruits and vegetables.

Enzyme Inactivation Index

Blanching involves briefly boiling produce to effectively inactivate enzymes, achieving a high Enzyme Inactivation Index that preserves quality and shelf life. Dry blanching, using hot air without water immersion, often results in a lower Enzyme Inactivation Index, leading to incomplete enzyme inactivation and reduced produce stability.

Nutrient Retention Ratio

Blanching with hot water or steam typically achieves a higher nutrient retention ratio compared to dry blanching, preserving vitamins such as vitamin C and B-complex more effectively. Dry blanching tends to cause greater nutrient loss due to prolonged heat exposure and lack of moisture, which accelerates degradation of heat-sensitive nutrients in produce.

Textural Integrity Score

Blanching maintains a higher Textural Integrity Score in produce by rapidly heating and then cooling, preserving firmness and cell structure more effectively than Dry Blanching, which can cause surface dehydration and uneven texture. Studies show that traditional water or steam blanching methods result in a Textural Integrity Score improvement of up to 30% compared to Dry Blanching, optimizing produce quality for further processing.

Non-aqueous Thermal Blanching

Non-aqueous thermal blanching uses hot oil or steam to rapidly inactivate enzymes in produce, preserving texture and nutrients better than traditional aqueous blanching which involves hot water immersion. Dry blanching minimizes nutrient leaching and reduces water usage, making it a more efficient method for high-value fruits and vegetables.

Blanching vs Dry Blanching for produce preparation Infographic

cookingdiff.com

cookingdiff.com