Boiling relies on high temperatures to break down food structure and extract flavors, while hydrocolloid gelling uses natural polymers to trap moisture and create a gel-like texture without intense heat. Unlike boiling, which can cause nutrient loss and texture changes, hydrocolloid gelling preserves nutrients and maintains a delicate consistency. Choosing between the two depends on desired texture and cooking time, as hydrocolloid gelling offers a controlled, gentle alternative to the rapid, high-heat process of boiling.

Table of Comparison

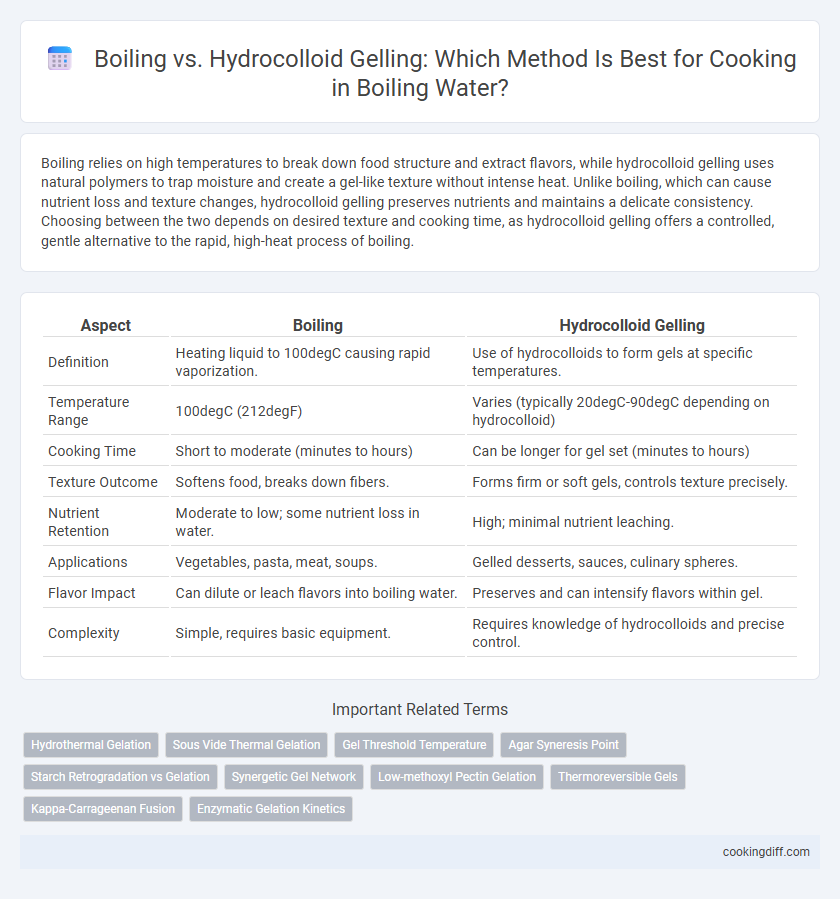

| Aspect | Boiling | Hydrocolloid Gelling |

|---|---|---|

| Definition | Heating liquid to 100degC causing rapid vaporization. | Use of hydrocolloids to form gels at specific temperatures. |

| Temperature Range | 100degC (212degF) | Varies (typically 20degC-90degC depending on hydrocolloid) |

| Cooking Time | Short to moderate (minutes to hours) | Can be longer for gel set (minutes to hours) |

| Texture Outcome | Softens food, breaks down fibers. | Forms firm or soft gels, controls texture precisely. |

| Nutrient Retention | Moderate to low; some nutrient loss in water. | High; minimal nutrient leaching. |

| Applications | Vegetables, pasta, meat, soups. | Gelled desserts, sauces, culinary spheres. |

| Flavor Impact | Can dilute or leach flavors into boiling water. | Preserves and can intensify flavors within gel. |

| Complexity | Simple, requires basic equipment. | Requires knowledge of hydrocolloids and precise control. |

Understanding Boiling: Basics and Applications in Cooking

Boiling involves heating a liquid until it reaches its boiling point, causing bubbles to form and rise continuously. This method is essential for cooking foods evenly, extracting flavors, and sterilizing ingredients effectively.

Unlike hydrocolloid gelling, boiling uses high temperatures to alter food textures rapidly. It is widely applied in preparing soups, pasta, and vegetables to achieve desired softness and consistency.

What Are Hydrocolloid Gelling Agents?

Hydrocolloid gelling agents are substances derived from natural polysaccharides and proteins that form gels when combined with water, offering unique textural properties in cooking. Unlike boiling, which relies on heat to alter food textures, hydrocolloids create stable gels at various temperatures, enhancing mouthfeel and presentation.

- Hydrocolloids form gels - They create structured, reversible gels that trap water, affecting viscosity and stability in food.

- Derived from natural sources - Common hydrocolloids include agar, carrageenan, and xanthan gum, each imparting distinct gelling properties.

- Used for texture control - They modify food texture without requiring prolonged heating, preserving flavor and nutrients.

Hydrocolloid gelling agents provide versatile alternatives to traditional boiling by enabling precise texture manipulation and innovative culinary applications.

Boiling vs Hydrocolloid Gelling: Key Differences

| Aspect | Boiling | Hydrocolloid Gelling |

|---|---|---|

| Process | Uses high-temperature water to cook food through heat transfer. | Involves the formation of gels by hydrocolloids through molecular interactions at lower temperatures. |

| Texture Outcome | Results in softened or cooked textures by breaking down fibers and proteins. | Creates unique gel-like textures by trapping water within a polymer network. |

| Culinary Applications | Common for cooking vegetables, pasta, and meats efficiently. | Used to modify mouthfeel, stabilize emulsions, and develop structured gels in modern gastronomy. |

Texture and Mouthfeel: Boiled Foods vs Gels

Boiling transforms the texture of foods by breaking down cell walls, resulting in a softer, more tender mouthfeel that is often perceived as moist and easily chewable. Hydrocolloid gelling, on the other hand, creates a structured matrix that provides a smooth, gel-like texture with controlled firmness and elasticity. The contrast between boiled foods and hydrocolloid gels lies in the tactile experience; boiled items typically offer a more fibrous, disintegrating sensation while gels deliver a uniform, cohesive bite that enhances mouthfeel variety in culinary applications.

Nutrient Retention: Boiling Compared to Hydrocolloid Gelling

Boiling causes significant nutrient loss in water-soluble vitamins like vitamin C and B-complex due to leaching, whereas hydrocolloid gelling minimizes nutrient degradation by encapsulating ingredients within a gel matrix. This encapsulation reduces direct heat exposure and limits nutrient diffusion, preserving essential vitamins and minerals more effectively.

- Nutrient Loss in Boiling - Water-soluble vitamins degrade or leach into cooking water during boiling, reducing overall nutritional value.

- Nutrient Preservation in Hydrocolloid Gelling - Hydrocolloid gels trap nutrients, protecting them from heat and water loss during cooking.

- Impact on Cooking Methods - Hydrocolloid gelling offers a superior method for retaining nutrients compared to traditional boiling in culinary applications.

Flavor Impact: Traditional Boiling vs Gelling Techniques

Boiling extracts and dilutes flavors due to prolonged exposure to high heat and water, often leading to a loss of aromatic compounds. Hydrocolloid gelling preserves concentrated flavors by encapsulating ingredients, reducing flavor loss during cooking.

- Boiling reduces flavor intensity - Water-soluble flavors diffuse into the cooking liquid, diminishing overall taste.

- Hydrocolloid gels maintain flavor integrity - They trap volatile compounds and prevent evaporation during heat processing.

- Gelling offers texture control - It enhances mouthfeel while retaining original flavor profiles, unlike boiling.

Versatility: Dishes Best Suited for Boiling or Hydrocolloid Gelling

Which cooking method offers greater versatility for different dishes: boiling or hydrocolloid gelling? Boiling excels in preparing hearty soups, stews, and pasta by evenly cooking ingredients through direct heat and water. Hydrocolloid gelling is ideal for delicate dishes like molecular gastronomy creations, gels, and fruit purees, providing precise texture control and unique presentation.

Time and Efficiency: Speed of Boiling vs Gelling Processes

Boiling rapidly raises the temperature of liquids, achieving cooking readiness within minutes due to direct heat transfer, which maximizes time efficiency for many recipes. Hydrocolloid gelling, however, relies on molecular interactions that form a gel matrix over a longer duration, often requiring precise temperature control and extended setting times.

Boiling is ideal for fast cooking applications where speed is critical, such as blanching or boiling pasta, often completing in under 10 minutes. Hydrocolloid gelling offers a controlled texture formation but can take from 30 minutes to several hours depending on the hydrocolloid type and concentration. This slower process may limit its use in scenarios demanding rapid preparation but excels in structured, stable culinary products.

Visual Appeal: Comparing Presentation with Boiling and Gelling

Boiling often results in a less structured appearance, causing ingredients to lose shape and blend into a more homogenous texture, which may reduce visual contrast on the plate. Hydrocolloid gelling preserves the form and creates distinct, sharp shapes with a glossy finish, enhancing the dish's artistic presentation.

Gelled preparations offer vibrant, translucent colors that maintain stability under heat, adding a sophisticated look compared to the often muted tones from boiling. This controlled setting of ingredients with hydrocolloids allows chefs to compose visually striking dishes that highlight individual components clearly.

Related Important Terms

Hydrothermal Gelation

Hydrothermal gelation induces gel formation by heating hydrocolloids in water, creating a structured network that enhances texture and moisture retention, unlike boiling, which rapidly denatures proteins and dissolves gelatinous components. The controlled temperature increase in hydrothermal gelation allows precise manipulation of gel strength and consistency, making it ideal for culinary applications requiring delicate textural properties.

Sous Vide Thermal Gelation

Sous vide thermal gelation leverages precise temperature control to activate hydrocolloid gelling agents, resulting in uniform texture and enhanced flavor retention compared to traditional boiling methods. Boiling often causes nutrient loss and uneven heat distribution, while sous vide maintains consistent gelation, improving the quality of hydrocolloid-based culinary preparations.

Gel Threshold Temperature

Boiling typically occurs at 100degC, rapidly heating ingredients but may degrade delicate textures, whereas hydrocolloid gelling initiates at specific gel threshold temperatures ranging from 40degC to 90degC depending on the hydrocolloid type, allowing precise control over gel formation and texture development. Understanding the gel threshold temperature is crucial to optimizing hydrocolloid gelling processes, ensuring stable gel structures without overheating beyond boiling point.

Agar Syneresis Point

Boiling causes water molecules to rapidly evaporate, often exceeding the syneresis point of agar, leading to contraction and water expulsion from the gel network. In contrast, hydrocolloid gelling with agar maintains structural integrity below the syneresis temperature, preserving moisture and texture in culinary applications.

Starch Retrogradation vs Gelation

Boiling causes starch granules to swell and gelatinize, leading to leaching of amylose and amylopectin, which upon cooling promotes starch retrogradation and recrystallization, affecting texture and shelf life. Hydrocolloid gelling forms a network by binding water and interacting with starch molecules, stabilizing the gel structure and reducing retrogradation, thereby enhancing food quality and shelf stability.

Synergetic Gel Network

Boiling induces phase transitions that disrupt molecular structures, whereas hydrocolloid gelling promotes the formation of a synergetic gel network by combining polysaccharides and proteins, enhancing texture and stability. This gel network retains water more effectively, reducing syneresis and improving mouthfeel compared to traditional boiling methods.

Low-methoxyl Pectin Gelation

Low-methoxyl pectin gelation relies on calcium ions to form a network during hydrocolloid gelling, producing a stable gel at lower temperatures compared to boiling. Boiling can degrade low-methoxyl pectin structure, whereas controlled hydrocolloid gelation preserves gel strength and texture in culinary applications.

Thermoreversible Gels

Boiling involves applying heat to reach the phase transition of water at 100degC, breaking down food structure, while hydrocolloid gelling uses thermoreversible gels like agar or gelatin that solidify upon cooling and remelt when reheated, offering precise texture control. Thermoreversible gels enable reversible sol-gel transitions without degradation, contrasting with boiling's irreversible protein denaturation and starch gelatinization processes.

Kappa-Carrageenan Fusion

Boiling and hydrocolloid gelling represent distinctly different cooking techniques, with boiling relying on heat to transition food from solid to liquid, while hydrocolloid gelling, particularly with kappa-carrageenan fusion, achieves texture transformation through molecular interactions without prolonged heat exposure. Kappa-carrageenan, extracted from red seaweed, forms strong, brittle gels when combined with potassium ions, offering chefs precise control over the gelation process and texture customization in culinary applications.

Boiling vs Hydrocolloid Gelling for Cooking Infographic

cookingdiff.com

cookingdiff.com