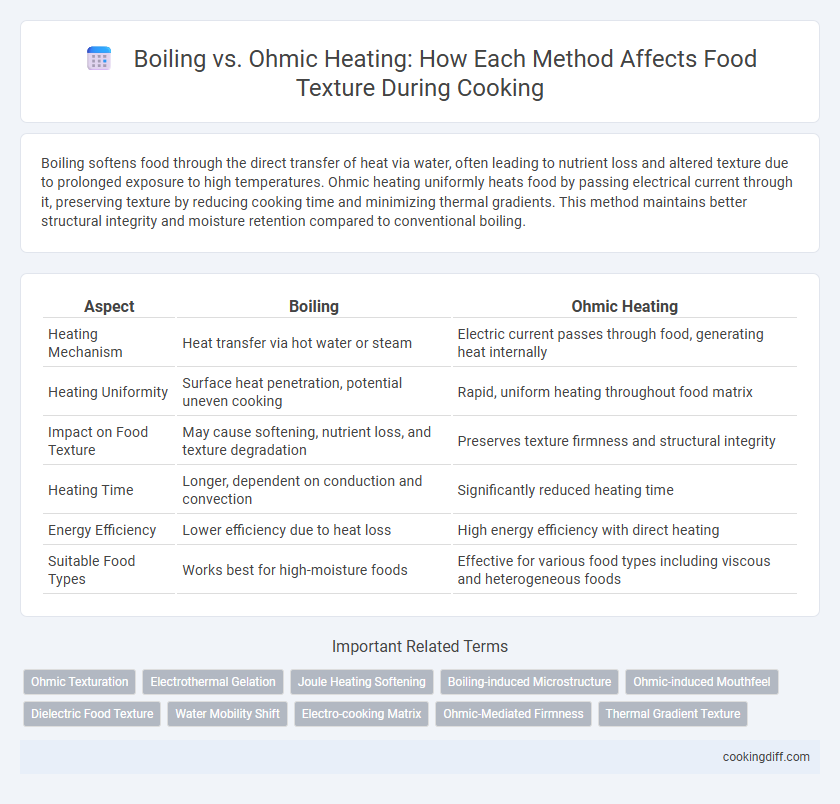

Boiling softens food through the direct transfer of heat via water, often leading to nutrient loss and altered texture due to prolonged exposure to high temperatures. Ohmic heating uniformly heats food by passing electrical current through it, preserving texture by reducing cooking time and minimizing thermal gradients. This method maintains better structural integrity and moisture retention compared to conventional boiling.

Table of Comparison

| Aspect | Boiling | Ohmic Heating |

|---|---|---|

| Heating Mechanism | Heat transfer via hot water or steam | Electric current passes through food, generating heat internally |

| Heating Uniformity | Surface heat penetration, potential uneven cooking | Rapid, uniform heating throughout food matrix |

| Impact on Food Texture | May cause softening, nutrient loss, and texture degradation | Preserves texture firmness and structural integrity |

| Heating Time | Longer, dependent on conduction and convection | Significantly reduced heating time |

| Energy Efficiency | Lower efficiency due to heat loss | High energy efficiency with direct heating |

| Suitable Food Types | Works best for high-moisture foods | Effective for various food types including viscous and heterogeneous foods |

Introduction to Boiling and Ohmic Heating

Boiling is a traditional cooking method that uses heat conduction through water to cook food, affecting texture by softening fibers and enabling moisture uptake. Ohmic heating employs electrical currents passing directly through food, causing internal heat generation that can preserve texture better due to uniform heating.

- Boiling Heat Transfer - Involves convection and conduction, leading to gradual and sometimes uneven texture changes in food.

- Ohmic Heating Process - Uses electrical resistance to generate heat internally, ensuring rapid and uniform cooking.

- Texture Impact - Boiling often results in softer textures, while ohmic heating maintains firmer and more consistent food structure.

Principles of Boiling in Food Preparation

Boiling involves heating food in water at 100degC to induce thermal softening, affecting texture by breaking down cell walls and proteins. Ohmic heating uses electrical currents to generate internal heat, resulting in more uniform cooking and potentially better texture retention.

- Boiling Principle - Heat is transferred from boiling water to food surface causing gradual heat penetration.

- Texture Impact - Prolonged boiling softens food by gelatinizing starch and denaturing proteins.

- Ohmic Heating Advantage - Direct internal heating reduces cooking time and minimizes texture degradation.

Understanding boiling's heat transfer mechanism helps optimize food texture compared to ohmic heating methods.

Ohmic Heating: Technology and Applications

Ohmic heating technology involves passing an electric current directly through food, generating rapid and uniform internal heat that preserves texture better than conventional boiling. This method reduces cooking time and minimizes nutrient loss, enhancing the overall food quality and texture.

Applications of ohmic heating in food processing include pasteurization and sterilization, where precise temperature control helps maintain the firmness and natural structure of fruits, vegetables, and meat products. Its ability to uniformly heat heterogeneous food materials makes it highly effective for improving texture while ensuring safety.

Comparing Heat Transfer Mechanisms

| Boiling transfers heat primarily through convection as hot water surrounds the food, resulting in relatively uniform heat distribution but slower penetration into dense textures. |

| Ohmic heating generates heat internally by passing electrical current directly through food, enabling rapid and volumetric heating that preserves texture better by reducing cooking time and minimizing nutrient loss. |

| Compared to boiling, ohmic heating offers more controlled temperature rise and reduces structural damage in food, making it ideal for maintaining desired textures in sensitive products. |

Effects on Food Texture: Boiling vs Ohmic Heating

Boiling cooks food through heat transfer from boiling water, often leading to texture softening and nutrient leaching. This method can cause uneven texture, especially in dense foods, as the surface softens faster than the interior.

Ohmic heating uses electrical currents to uniformly heat food internally, preserving firmer texture and minimizing nutrient loss. This technique results in a more consistent texture, maintaining food structure better than boiling.

Nutrient Retention and Texture Differences

How do boiling and ohmic heating compare in terms of nutrient retention and food texture? Boiling often leads to significant nutrient loss due to prolonged exposure to high temperatures and water leaching, whereas ohmic heating preserves more nutrients by rapidly heating food through electrical resistance. Texture-wise, ohmic heating maintains firmer and more uniform food structures, while boiling can result in softer, less consistent textures due to uneven heat distribution.

Case Studies: Texture in Vegetables and Meats

Case studies reveal that ohmic heating preserves the firmness and cellular integrity of vegetables significantly better than traditional boiling, resulting in a more desirable texture. In meat products, ohmic heating reduces cooking time and retains juiciness and tenderness by evenly distributing heat at the molecular level. Research highlights that ohmic heating minimizes nutrient loss while preventing over-softening, a common issue in boiling that adversely affects sensory quality.

Energy Efficiency and Process Control

Boiling consumes significant energy due to the high heat capacity of water, resulting in less efficient energy transfer compared to ohmic heating, which directly heats food through electrical resistance. Ohmic heating offers superior process control by allowing rapid and uniform temperature increases, minimizing overcooking and texture degradation.

Energy efficiency in ohmic heating reduces processing time and energy costs, enhancing sustainability in food production. Process control with ohmic heating enables precise temperature management, preserving texture and nutritional quality better than conventional boiling. These advantages make ohmic heating a preferred method for maintaining desirable food texture while optimizing energy use.

Consumer Perception of Texture Changes

Boiling tends to soften food textures through prolonged exposure to high temperatures and water, often perceived by consumers as traditional and natural but sometimes resulting in mushiness. Ohmic heating uses electrical currents to rapidly heat food internally, preserving firmer textures that many consumers associate with freshness and higher quality. Studies indicate that consumers prefer the texture of ohmic-heated foods due to reduced cooking time and minimal nutrient loss, enhancing overall acceptance.

Related Important Terms

Ohmic Texturation

Ohmic heating improves food texture by providing rapid and uniform heating, reducing cooking time and minimizing nutrient loss compared to traditional boiling. This method enhances cell structure retention and preserves natural food qualities, resulting in better texture and mouthfeel.

Electrothermal Gelation

Electrothermal gelation during ohmic heating enables uniform and rapid heat distribution, resulting in improved food texture and reduced processing time compared to conventional boiling methods. This precise control over temperature gradients enhances protein denaturation and starch gelatinization, producing a more consistent gel network and superior texture in food products.

Joule Heating Softening

Joule heating in ohmic heating rapidly softens food textures by uniformly passing electric currents through the material, resulting in faster and more homogeneous heat distribution compared to traditional boiling. This method preserves structural integrity and enhances tenderness while reducing nutrient loss and processing time.

Boiling-induced Microstructure

Boiling induces significant microstructural changes in food by causing cell wall breakdown and starch gelatinization, resulting in a softer texture and increased water absorption. In contrast, ohmic heating generates uniform internal heating that preserves cellular integrity better, maintaining firmer textures and reducing nutrient loss.

Ohmic-induced Mouthfeel

Ohmic heating enhances food texture by enabling uniform heat distribution through electrical resistance, preserving cellular structure and resulting in a tender, moist mouthfeel compared to the uneven texture often caused by conventional boiling. This method reduces nutrient loss and prevents overcooking, contributing to improved sensory properties and overall food quality.

Dielectric Food Texture

Boiling alters dielectric food texture by causing surface gelatinization and moisture loss, resulting in softer, less uniform consistency, while Ohmic Heating preserves dielectric properties by uniformly heating food through electrical resistance, maintaining crispness and improving textural integrity. Dielectric parameters such as permittivity and conductivity directly influence the efficiency of Ohmic Heating in retaining cell structure and minimizing texture degradation.

Water Mobility Shift

Boiling reduces water mobility by creating uniform heat transfer, resulting in a consistent softening of food texture through cell wall breakdown and moisture loss. Ohmic heating induces a rapid water mobility shift by directly passing electric current through food, causing faster intracellular water redistribution and preserving firmer textures compared to conventional boiling.

Electro-cooking Matrix

Boiling alters food texture primarily through heat transfer via water, causing cell wall breakdown and softening, while ohmic heating relies on electric current passing directly through the food, resulting in uniform internal heating that better preserves structural integrity. The electro-cooking matrix of ohmic heating minimizes overcooking and uneven texture by generating heat volumetrically, enhancing tenderness without excessive moisture loss compared to traditional boiling.

Ohmic-Mediated Firmness

Ohmic heating enhances food texture by producing uniform internal heating, resulting in a more consistent firmness compared to conventional boiling, which often causes uneven softening. The rapid volumetric heating in ohmic processes preserves cellular structure and reduces nutrient loss, optimizing firmness and overall food quality.

Boiling vs Ohmic Heating for food texture. Infographic

cookingdiff.com

cookingdiff.com