Metal whisks provide robust durability and maintain their shape well when used for boiling, making them ideal for heavy-duty stirring tasks. Spiral whisks excel at incorporating air and mixing liquids gently, but may not withstand the high heat and vigorous agitation required during boiling. Choosing between a metal and spiral whisk depends on the intensity of boiling and the need for durability versus gentle blending.

Table of Comparison

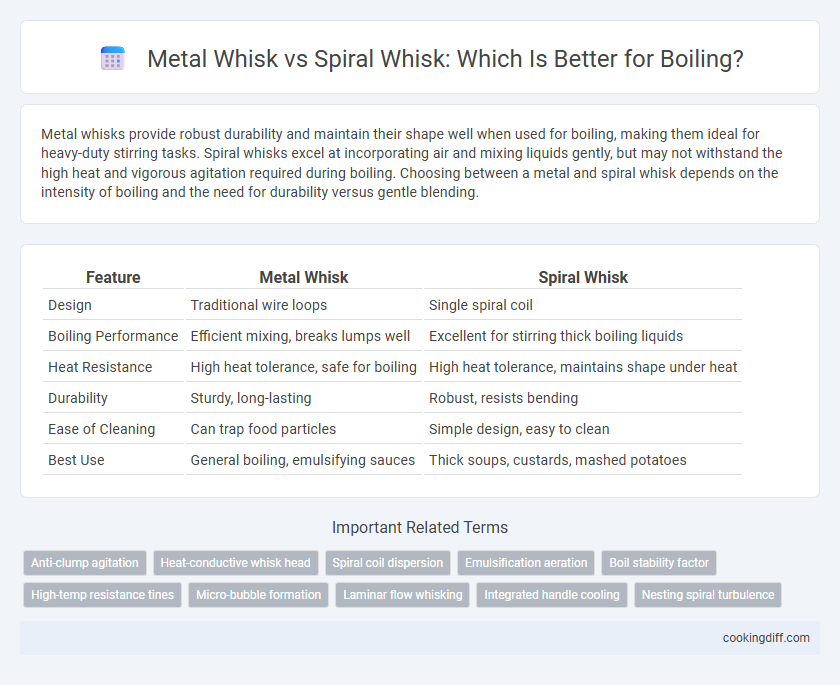

| Feature | Metal Whisk | Spiral Whisk |

|---|---|---|

| Design | Traditional wire loops | Single spiral coil |

| Boiling Performance | Efficient mixing, breaks lumps well | Excellent for stirring thick boiling liquids |

| Heat Resistance | High heat tolerance, safe for boiling | High heat tolerance, maintains shape under heat |

| Durability | Sturdy, long-lasting | Robust, resists bending |

| Ease of Cleaning | Can trap food particles | Simple design, easy to clean |

| Best Use | General boiling, emulsifying sauces | Thick soups, custards, mashed potatoes |

Introduction to Boiling and Whisk Selection

| Boiling involves heating liquid to 100degC, creating steam and bubbles critical for cooking processes. |

| Metal whisks offer durability and heat resistance, making them ideal for stirring boiling liquids without deformation. |

| Spiral whisks, with their flexible coil design, excel in aeration but may lack the rigidity needed for vigorous stirring in boiling pots. |

Understanding Metal Whisks: Design and Function

Metal whisks, including both metal and spiral designs, excel in heat resistance and durability, making them ideal for boiling tasks. Their construction ensures efficient mixing and aeration while withstanding high temperatures without warping or melting.

- Metal Whisk Rigidity - Metal whisks maintain structural integrity under boiling conditions, providing consistent stirring without bending.

- Spiral Whisk Flexibility - Spiral whisks feature a coiled design that enhances mixing efficiency in dense or liquid ingredients during boiling.

- Heat Conductivity - Both metal and spiral whisks conduct heat safely but avoid transferring excessive heat to the handle, ensuring safe handling during boiling.

Exploring Spiral Whisks: Unique Features

Spiral whisks excel in breaking down clumps during boiling, providing smoother mixtures compared to traditional metal whisks. Their unique coil design ensures efficient aeration and faster incorporation of ingredients in hot liquids.

- Spiral Coil Structure - The uniquely coiled wire allows for superior mixing by reaching into corners of pots and pans.

- Enhanced Aeration - Spiral whisks introduce more air into boiling mixtures, improving texture and consistency.

- Durable Heat Resistance - Made from stainless steel, spiral whisks maintain shape and functionality under high boiling temperatures.

How Metal Whisks Perform During Boiling

Metal whisks excel during boiling due to their durability and heat resistance, allowing them to maintain shape and function without melting or warping. Their rigid construction helps efficiently incorporate ingredients in hot liquids, providing consistent stirring performance.

Compared to spiral whisks, metal whisks conduct heat quickly but remain sturdy, making them ideal for thick sauces and custards that require vigorous stirring at high temperatures. Spiral whisks can trap more air, but may not withstand prolonged exposure to boiling water as effectively. Overall, metal whisks offer superior longevity and reliability when working with boiling liquids in professional and home kitchens.

Spiral Whisks’ Effectiveness in Boiling Techniques

Spiral whisks excel in boiling techniques by creating intense, localized agitation, which accelerates heat distribution and prevents scorching in sauces or custards. Their tightly coiled design allows for efficient incorporation of ingredients, ensuring a smooth and consistent texture during boiling processes.

Compared to metal whisks, spiral whisks maintain better control over stirring in viscous mixtures, reducing the risk of boiling over or clumping. Their effectiveness in managing rapid temperature changes makes them ideal for emulsifying and thickening hot liquids.

Comparing Mixing Efficiency: Metal vs Spiral Whisks

Metal whisks offer superior durability and heat resistance, making them ideal for boiling tasks that require vigorous mixing. Spiral whisks excel at incorporating air and quickly blending ingredients due to their unique shape, but may be less effective in high-heat boiling situations. Choosing between metal and spiral whisks depends on the intensity of mixing needed and the temperature sensitivity of the ingredients involved.

Heat Resistance: Metal Whisk vs Spiral Whisk

Which whisk offers better heat resistance for boiling tasks, metal or spiral? Metal whisks, typically made of stainless steel, withstand higher temperatures and maintain durability during prolonged boiling. Spiral whisks, often coated or made with mixed materials, may deform or lose effectiveness under intense heat.

Best Recipes for Each Whisk When Boiling

Metal whisks excel in stirring thick sauces and custards during boiling, making them ideal for recipes like cheese sauces and creamy soups. Spiral whisks are perfect for incorporating air into lighter mixtures such as boiling eggs for fluffy scrambled egg recipes or delicate batters. Choosing the right whisk enhances texture and consistency, optimizing results in boiling-based dishes.

Cleaning and Maintenance After Boiling

Metal whisks, especially those made from stainless steel, are highly resistant to heat and corrosion, making them easier to clean after boiling. Their solid construction prevents food particles from getting trapped, reducing the effort required for thorough maintenance.

Spiral whisks, with their multiple loops, tend to trap more residue, demanding more meticulous cleaning to avoid build-up and potential rust. Regular soaking and careful scrubbing are crucial to maintain the longevity of spiral whisks used during boiling.

Related Important Terms

Anti-clump agitation

A metal whisk provides firmer, more consistent anti-clump agitation during boiling due to its rigid wires that effectively break up lumps in sauces and batters. Spiral whisks, with their coiled design, offer gentler mixing but may be less efficient at preventing clumps in thick boiling mixtures.

Heat-conductive whisk head

Metal whisks with heat-conductive heads facilitate faster mixing and heat transfer during boiling compared to spiral whisks, which often have insulated or less conductive wires that slow the process. The solid metal construction of a metal whisk enhances thermal efficiency, making it ideal for maintaining consistent temperature and preventing uneven cooking in boiling applications.

Spiral coil dispersion

Spiral whisks feature a coil design that efficiently disperses heat and agitation in boiling liquids, promoting faster and more even mixing compared to metal whisks. The coil's flexibility allows for better incorporation of ingredients and prevents clumping during high-temperature cooking processes.

Emulsification aeration

Metal whisks provide superior emulsification and aeration during boiling due to their rigid structure, which efficiently incorporates air and blends ingredients more thoroughly. Spiral whisks, with their flexible loops, offer gentler mixing but may be less effective in creating stable emulsions and consistent aeration under high heat conditions.

Boil stability factor

Metal whisks provide superior boil stability due to their rigid construction, allowing consistent agitation and preventing hotspots during boiling. Spiral whisks, with their flexible design, may cause uneven stirring that affects temperature distribution, reducing boil stability efficiency.

High-temp resistance tines

Metal whisks with stainless steel tines offer superior high-temperature resistance compared to spiral whisks, ensuring durability and maintaining structural integrity during prolonged boiling. Spiral whisks often feature more flexible wires that may deform or lose shape under intense heat, making metal tines ideal for heavy-duty boiling tasks.

Micro-bubble formation

Metal whisks generate more micro-bubbles during boiling compared to spiral whisks due to their rigid structure and efficient agitation of liquid molecules, enhancing heat transfer and preventing hotspots. Spiral whisks produce fewer micro-bubbles, resulting in less effective boiling turbulence and slower heat distribution.

Laminar flow whisking

Metal whisks generate efficient laminar flow during boiling, enhancing heat distribution and reducing foam formation compared to spiral whisks, which tend to create turbulent flow that disrupts smooth liquid motion. The rigid structure of metal whisks facilitates consistent stirring, promoting even temperature dispersion essential for precise boiling control.

Integrated handle cooling

Metal whisks with integrated handle cooling provide superior heat resistance during boiling, preventing burns and ensuring safe, comfortable grip. Spiral whisks lack this feature, making them prone to transferring heat quickly, which can hinder prolonged use over boiling pots.

Metal whisk vs spiral whisk for boiling. Infographic

cookingdiff.com

cookingdiff.com