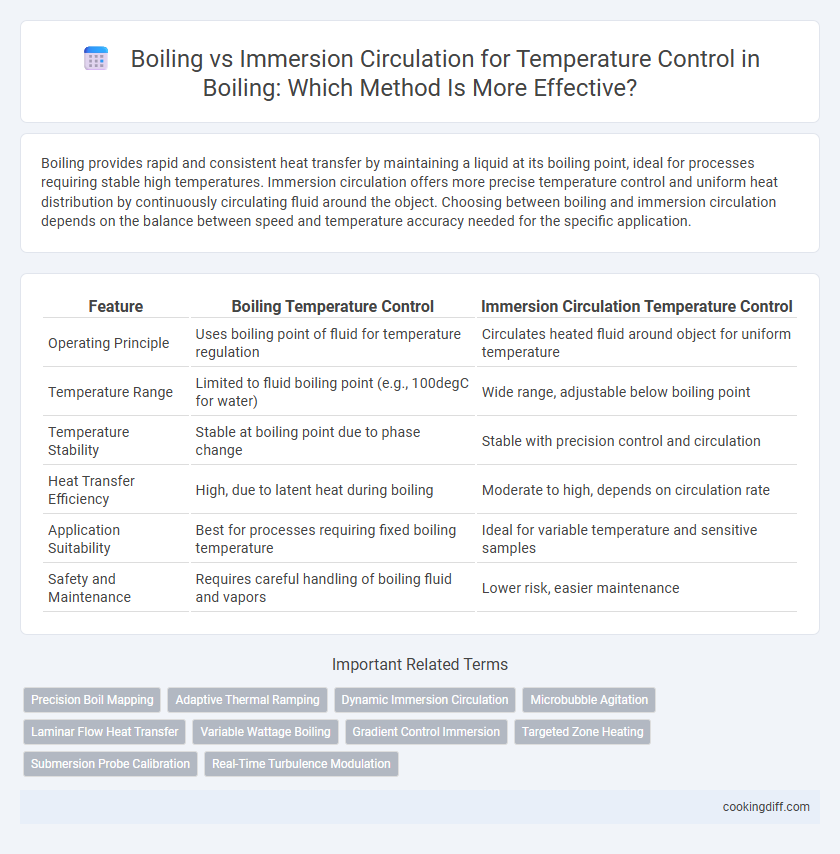

Boiling provides rapid and consistent heat transfer by maintaining a liquid at its boiling point, ideal for processes requiring stable high temperatures. Immersion circulation offers more precise temperature control and uniform heat distribution by continuously circulating fluid around the object. Choosing between boiling and immersion circulation depends on the balance between speed and temperature accuracy needed for the specific application.

Table of Comparison

| Feature | Boiling Temperature Control | Immersion Circulation Temperature Control |

|---|---|---|

| Operating Principle | Uses boiling point of fluid for temperature regulation | Circulates heated fluid around object for uniform temperature |

| Temperature Range | Limited to fluid boiling point (e.g., 100degC for water) | Wide range, adjustable below boiling point |

| Temperature Stability | Stable at boiling point due to phase change | Stable with precision control and circulation |

| Heat Transfer Efficiency | High, due to latent heat during boiling | Moderate to high, depends on circulation rate |

| Application Suitability | Best for processes requiring fixed boiling temperature | Ideal for variable temperature and sensitive samples |

| Safety and Maintenance | Requires careful handling of boiling fluid and vapors | Lower risk, easier maintenance |

Understanding Boiling: Traditional Temperature Control

Boiling provides precise temperature control by maintaining a consistent phase change at the liquid's boiling point, which ensures stable thermal conditions. Immersion circulation relies on fluid convection to evenly distribute heat but may exhibit slower response times compared to boiling systems.

- Boiling ensures uniform temperature - The latent heat of vaporization stabilizes temperature during phase transition.

- Immersion circulation enables fluid movement - Circulating liquid promotes even heat distribution without phase change.

- Boiling systems offer rapid temperature control - Direct vaporization accelerates heat transfer efficiency for thermal processes.

What is Immersion Circulation?

What is immersion circulation in temperature control? Immersion circulation involves submerging a temperature-controlled fluid directly around the sample or equipment to maintain precise thermal conditions. This method ensures uniform heat distribution and faster temperature stabilization compared to boiling, which relies on vapor phase heat transfer.

Key Differences Between Boiling and Immersion Circulation

| Aspect | Boiling | Immersion Circulation |

|---|---|---|

| Temperature Range | Can reach boiling point; ideal for high-temperature processes | Operates below boiling point; suitable for precise temperature control |

| Heat Transfer Mechanism | Heat transfer occurs through phase change with vapor formation | Heat transfer via circulating fluid around the object for uniform temperature |

| Applications | Used in sterilization, cooking, and chemical reactions requiring boiling | Commonly used in laboratories and industries for consistent temperature maintenance |

| Energy Efficiency | Higher energy consumption due to latent heat of vaporization | Lower energy use with controlled fluid circulation reducing heat loss |

| Temperature Stability | Subject to fluctuations due to vapor bubble formation | Provides stable and uniform temperature throughout the bath |

Precision and Consistency in Temperature Control

Boiling temperature control achieves precision by maintaining a stable phase change point, which naturally regulates temperature around the boiling point of the liquid. Immersion circulation offers consistent temperature control by actively circulating fluid, minimizing hot spots and enhancing uniform heat distribution throughout the system.

Boiling systems provide inherent precision due to the fixed temperature plateau during the phase transition, ideal for processes requiring strict temperature adherence. Immersion circulation excels in ensuring consistent temperature across varying loads and container sizes through dynamic fluid movement and feedback mechanisms.

Energy Efficiency: Boiling vs Immersion Circulation

Boiling systems typically consume more energy due to the latent heat required to transition liquid to vapor, often resulting in higher operational costs compared to immersion circulation. Immersion circulation systems circulate fluid around a heated element, maintaining temperature with lower energy consumption and improving overall efficiency. This makes immersion circulation a preferred choice for precise temperature control applications with minimized energy use.

Cooking Results: Texture, Flavor, and Nutrient Retention

Boiling rapidly cooks food but can lead to uneven texture and nutrient loss due to high temperatures and agitation. Immersion circulation offers precise temperature control, resulting in consistent texture, enhanced flavor retention, and improved nutrient preservation.

- Texture Control - Immersion circulation maintains steady temperatures, preventing overcooking and preserving food's natural firmness and moisture.

- Flavor Preservation - Lower, controlled temperatures reduce volatile flavor compound loss compared to vigorous boiling.

- Nutrient Retention - Minimal water agitation in immersion circulation limits nutrient leaching, enhancing the overall nutritional quality of cooked food.

Time Considerations: Speed and Convenience

Boiling temperature control achieves rapid heat transfer by directly vaporizing the liquid, resulting in faster temperature stabilization compared to immersion circulation. Immersion circulation relies on circulating fluid to evenly distribute heat, which can take longer due to slower fluid dynamics and thermal conduction. For applications prioritizing speed and convenience, boiling offers a more immediate temperature adjustment, while immersion circulation provides steadier, long-term control.

Equipment and Setup Requirements

Boiling systems require robust heat exchangers and steam generators capable of maintaining precise temperature control through phase change dynamics. Immersion circulation setups utilize submerged heaters and circulation pumps designed to evenly distribute heat within the fluid, minimizing temperature gradients.

Boiling equipment generally demands insulated vessels to handle high temperatures and pressure variations safely, along with pressure relief valves and condensers. In contrast, immersion circulation systems focus on compact, corrosion-resistant materials and modular components that facilitate easy integration and maintenance.

Best Uses for Boiling and Immersion Circulation

Boiling is best suited for applications requiring rapid temperature increases and precise control of high temperatures, such as sterilization and chemical reactions. Immersion circulation excels in maintaining uniform temperature distributions in delicate processes like biological sample incubation or electronic component testing.

Boiling offers efficient heat transfer for processes needing consistent high-temperature environments, ideal in laboratories and industrial settings. Immersion circulation provides gentle, consistent heating by circulating fluid around the sample, preventing hotspots and ensuring even temperature maintenance. Selecting between boiling and immersion circulation depends on the required temperature range, control precision, and sample sensitivity in the application.

Related Important Terms

Precision Boil Mapping

Precision Boil Mapping demonstrates that boiling offers superior temperature uniformity compared to immersion circulation, minimizing thermal gradients in controlled environments. This enhanced precision in boiling ensures consistent heat distribution critical for processes requiring exact thermal management.

Adaptive Thermal Ramping

Adaptive Thermal Ramping in boiling offers precise temperature control by rapidly adjusting heat input based on real-time feedback, outperforming immersion circulation methods that rely on slower fluid convection. Boiling enables more efficient heat transfer through vaporization dynamics, ensuring faster and more accurate thermal ramping critical for sensitive processes.

Dynamic Immersion Circulation

Dynamic immersion circulation enhances temperature control by continuously moving the fluid around the heated object, ensuring uniform heat distribution and minimizing hotspots compared to boiling methods. This technique optimizes thermal regulation efficiency in laboratory and industrial applications, providing precise temperature stability for sensitive processes.

Microbubble Agitation

Boiling temperature control leverages microbubble agitation to enhance heat transfer efficiency by disrupting boundary layers and promoting uniform temperature distribution, while immersion circulation primarily relies on the fluid's bulk movement without targeted microbubble dynamics. Microbubble agitation in boiling systems intensifies convective heat transfer and accelerates phase change processes, offering superior thermal regulation compared to conventional immersion circulation methods.

Laminar Flow Heat Transfer

Boiling heat transfer achieves higher thermal efficiency due to the phase change mechanism enhancing laminar flow convection, while immersion circulation relies on forced laminar flow without phase change, resulting in lower heat transfer coefficients. Boiling generates localized turbulence and micro-convection at the liquid-solid interface, improving temperature control precision compared to the steady, uniform laminar flow found in immersion circulation systems.

Variable Wattage Boiling

Variable Wattage Boiling offers precise temperature control by adjusting heating power in response to real-time thermal changes, outperforming Immersion Circulation which relies on constant fluid movement for temperature stability. This dynamic wattage modulation enhances energy efficiency and accelerates heat transfer rates, making it ideal for applications demanding rapid and accurate temperature adjustments.

Gradient Control Immersion

Gradient Control Immersion offers precise temperature uniformity by circulating fluid at controlled gradients, reducing hotspots common in boiling methods. This optimized temperature control enhances experimental accuracy and equipment longevity compared to traditional boiling and immersion circulation techniques.

Targeted Zone Heating

Boiling provides targeted zone heating by directly applying heat through phase change, resulting in rapid and localized temperature control ideal for processes requiring precise thermal regulation. Immersion circulation distributes heat uniformly by circulating a heated fluid around the object, offering consistent but less focused temperature management across the entire volume.

Submersion Probe Calibration

Boiling provides stable temperature benchmarks for submersion probe calibration with minimal fluid stratification, ensuring consistent thermal contact compared to immersion circulation systems. Immersion circulation offers rapid temperature uniformity but may introduce flow-induced temperature fluctuations affecting probe accuracy during calibration.

Boiling vs Immersion circulation for temperature control. Infographic

cookingdiff.com

cookingdiff.com