Boiling provides a rapid and straightforward method for heating liquids by reaching the water's boiling point, but it lacks precise temperature control, often leading to fluctuations and inconsistencies. Precision thermocirculation systems maintain steady temperatures with exact control, ensuring consistent heating essential for sensitive cooking and scientific applications. This accuracy minimizes overheating risks and improves overall process reliability compared to traditional boiling methods.

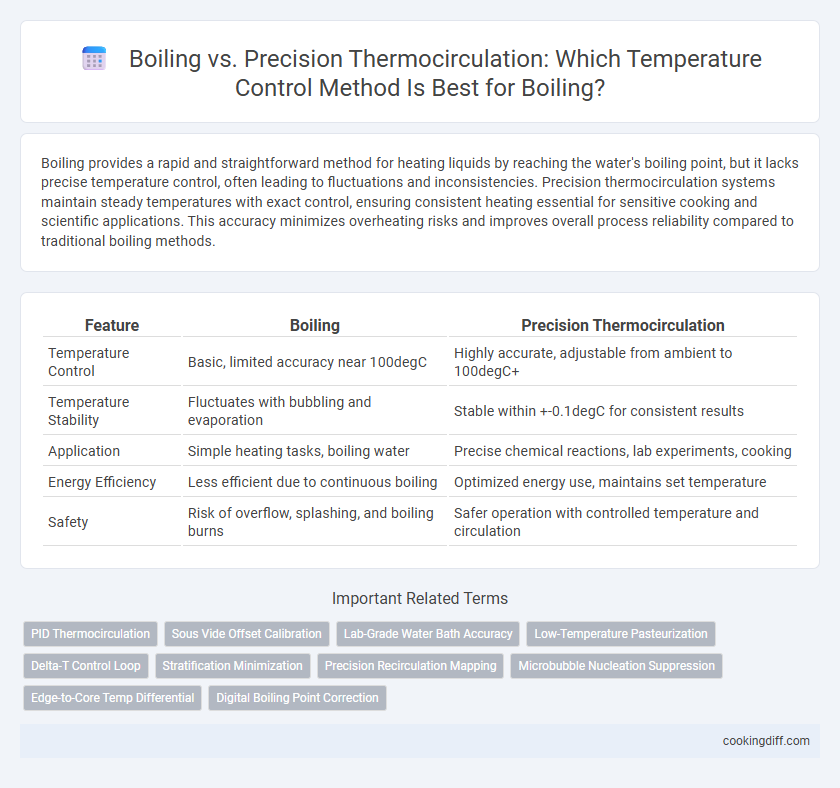

Table of Comparison

| Feature | Boiling | Precision Thermocirculation |

|---|---|---|

| Temperature Control | Basic, limited accuracy near 100degC | Highly accurate, adjustable from ambient to 100degC+ |

| Temperature Stability | Fluctuates with bubbling and evaporation | Stable within +-0.1degC for consistent results |

| Application | Simple heating tasks, boiling water | Precise chemical reactions, lab experiments, cooking |

| Energy Efficiency | Less efficient due to continuous boiling | Optimized energy use, maintains set temperature |

| Safety | Risk of overflow, splashing, and boiling burns | Safer operation with controlled temperature and circulation |

Introduction to Boiling and Precision Thermocirculation

What distinguishes boiling from precision thermocirculation in temperature control? Boiling is the phase transition of a liquid to vapor at its boiling point, primarily used for high-temperature applications without precise regulation. Precision thermocirculation employs advanced temperature sensors and circulators to maintain consistent, exact temperatures ideal for scientific and culinary processes.

Fundamental Principles of Water Boiling

Water boiling occurs when its vapor pressure equals the surrounding atmospheric pressure, causing a phase change from liquid to gas at 100degC under standard conditions. Precision thermocirculation maintains a stable temperature by circulating heated fluid around the vessel, avoiding the random fluctuations and localized hotspots typical of boiling. This fundamental principle makes precision thermocirculation ideal for applications requiring consistent temperature control rather than the intense heat transfer associated with boiling.

How Precision Thermocirculation Works

Precision thermocirculation maintains temperature by circulating a fluid through a heated jacket or coil, ensuring consistent heat transfer and uniform temperature distribution. This method uses advanced sensors and digital controls to achieve temperature stability within +-0.1degC, far superior to traditional boiling methods.

Boiling relies on the phase change of water at 100degC, which limits precise temperature control and can cause fluctuations during the process. Precision thermocirculators avoid these fluctuations by maintaining a constant liquid temperature, ideal for sensitive applications requiring exact thermal conditions.

Temperature Accuracy: Boiling vs Thermocirculation

Boiling provides a fixed temperature of 100degC at standard atmospheric pressure, which limits temperature accuracy for culinary precision. Precision thermocirculation operates within a specific temperature range, allowing control with an accuracy of +-0.1degC for consistent cooking results.

Thermocirculators maintain stable water temperatures without fluctuations, crucial for recipes requiring precise thermal conditions. In contrast, boiling can cause variable temperatures due to heat turbulence and evaporation, reducing reliability for delicate temperature control.

Energy Efficiency Comparison

| Boiling | Uses direct heat to reach 100degC quickly but results in significant energy loss due to steam evaporation and heat dispersion. Energy efficiency typically ranges from 50-60%, making it less ideal for precise temperature control. |

| Precision Thermocirculation | Maintains stable temperatures with minimal fluctuation by circulating heated fluid; energy efficiency exceeds 85% by reducing heat loss and optimizing thermal transfer, providing better energy savings and control accuracy for culinary and scientific applications. |

Impact on Food Texture and Flavor

Boiling rapidly cooks food at high temperatures, often leading to nutrient loss and texture degradation. Precision thermocirculation maintains stable, controlled temperatures, preserving delicate textures and enhancing flavor complexity.

- Boiling causes uneven cooking - The aggressive heat can result in overcooked exteriors and undercooked interiors, negatively impacting texture.

- Precision thermocirculation ensures consistent temperature - This method prevents overheating, allowing for uniform texture development and flavor retention.

- Flavor compounds remain intact with precision thermocirculation - Lower, stable temperatures minimize flavor loss compared to boiling's high-heat evaporation.

Versatility in Cooking Applications

Boiling provides rapid temperature increase but lacks precise heat control, limiting its effectiveness for delicate cooking tasks. Precision thermocirculation offers consistent temperature maintenance, enabling a wider range of culinary techniques with superior results.

- Boiling - Ideal for high-heat cooking methods like boiling pasta or vegetables but unsuitable for precise temperature-sensitive recipes.

- Precision Thermocirculation - Enables low and stable temperatures essential for sous vide cooking and slow-cooked dishes.

- Versatility - Thermocirculation devices adapt to various cooking methods, enhancing texture and flavor through controlled heat application.

Safety Considerations in Both Methods

Boiling poses safety risks such as burns and pressure buildup, requiring careful handling and equipment maintenance to prevent accidents. Precision thermocirculation offers enhanced safety by maintaining stable temperatures below boiling point, reducing the chance of scalding or overheating. Both methods demand proper monitoring, but precision thermocirculation minimizes hazards through precise temperature control and automated shutoff features.

Equipment Cost and Maintenance

Boiling setups generally incur lower initial equipment costs compared to precision thermocirculators, which require advanced technology for consistent temperature control. Maintenance of boiling equipment is simpler but less precise, whereas thermocirculators demand regular calibration and service to maintain accuracy.

- Lower upfront cost - Boiling equipment is typically less expensive due to basic design and materials.

- Complexity in maintenance - Precision thermocirculators need specialized parts and expertise for upkeep.

- Durability considerations - Boiling setups have fewer components, reducing potential failure points and service frequency.

Investing in precision thermocirculators offers better long-term temperature stability despite higher costs and maintenance requirements.

Related Important Terms

PID Thermocirculation

PID thermocirculation delivers superior temperature control compared to boiling by maintaining precise, stable temperatures through continuous feedback loops, eliminating the fluctuations common in traditional boiling methods. This method enhances experimental accuracy and reproducibility in sensitive applications by minimizing thermal gradients and overshoot during heating processes.

Sous Vide Offset Calibration

Sous Vide offset calibration ensures precise temperature control by compensating for the discrepancy between boiling water temperature and the device's sensor reading, which is critical for maintaining consistent cooking results. Unlike conventional boiling methods that rely on unstable surface temperatures, precision thermocirculation circulates water to sustain a uniform temperature, minimizing temperature fluctuations during sous vide cooking.

Lab-Grade Water Bath Accuracy

Lab-grade water baths using precision thermocirculation achieve more consistent temperature control within +-0.1degC compared to traditional boiling methods, which often fluctuate beyond +-1degC. This enhanced accuracy ensures reliable repeatability in sensitive experiments requiring stable thermal environments.

Low-Temperature Pasteurization

Boiling achieves temperature control by reaching 100degC, which can degrade nutrient quality in low-temperature pasteurization, whereas precision thermocirculation maintains exact temperatures between 55degC and 75degC, preserving food integrity. Precision thermocirculation systems enhance microbial safety and enzymatic activity control without overcooking, optimizing pasteurization effectiveness for sensitive products.

Delta-T Control Loop

Boiling relies on direct phase change heat transfer, introducing temperature fluctuations that complicate maintaining a stable Delta-T control loop, whereas precision thermocirculation systems use advanced sensors and feedback mechanisms to achieve consistent, narrow Delta-T ranges for precise temperature regulation. This controlled Delta-T environment minimizes thermal gradients, enhancing reproducibility and energy efficiency in sensitive applications.

Stratification Minimization

Precision thermocirculation reduces temperature stratification more effectively than boiling by maintaining uniform heat distribution through continuous liquid movement. This method ensures consistent temperature control critical for sensitive chemical reactions and biological processes where stratification disrupts accuracy.

Precision Recirculation Mapping

Precision thermocirculation enables accurate temperature control by continuously circulating heated liquid to maintain uniformity, whereas boiling relies on phase change at a fixed temperature with less control over spatial temperature variation. Precision recirculation mapping enhances this process by precisely monitoring and adjusting flow patterns to achieve optimal thermal homogeneity within the system.

Microbubble Nucleation Suppression

Boiling involves microbubble nucleation that can cause temperature fluctuations and reduce control precision, whereas Precision Thermocirculation maintains stable temperatures by suppressing microbubble formation through consistent fluid circulation. This suppression of microbubble nucleation enhances temperature uniformity and process reliability in Precision Thermocirculation systems.

Edge-to-Core Temp Differential

Boiling causes significant edge-to-core temperature differentials due to uneven heat distribution, which can compromise precise cooking control. Precision thermocirculation systems maintain uniform temperature by continuously circulating heated fluid, minimizing edge-to-core temperature gaps for consistent results.

Boiling vs Precision Thermocirculation for temperature control. Infographic

cookingdiff.com

cookingdiff.com