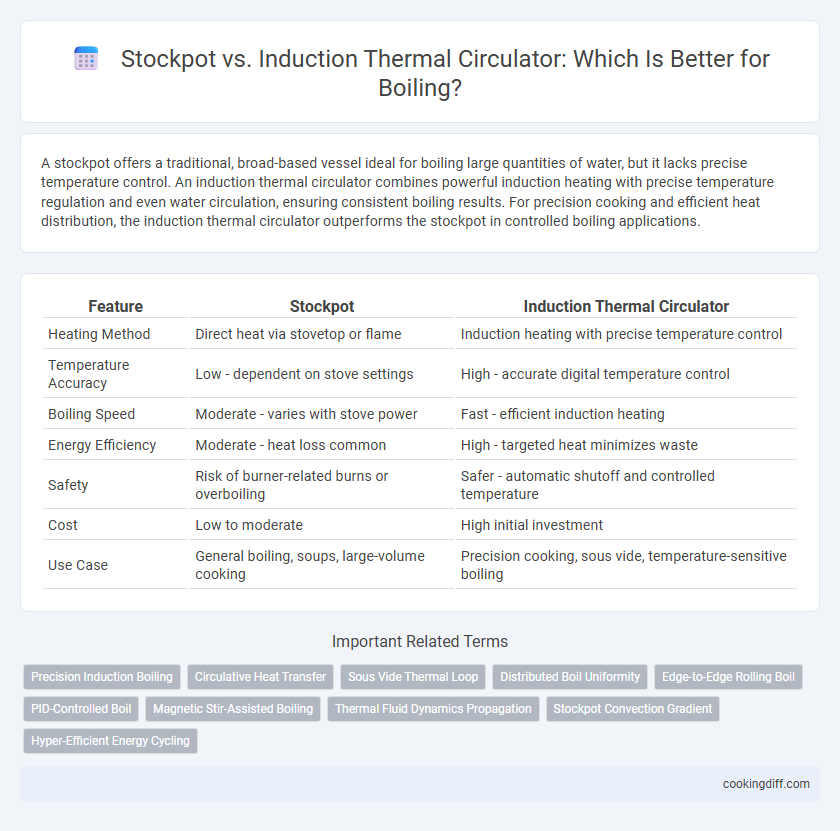

A stockpot offers a traditional, broad-based vessel ideal for boiling large quantities of water, but it lacks precise temperature control. An induction thermal circulator combines powerful induction heating with precise temperature regulation and even water circulation, ensuring consistent boiling results. For precision cooking and efficient heat distribution, the induction thermal circulator outperforms the stockpot in controlled boiling applications.

Table of Comparison

| Feature | Stockpot | Induction Thermal Circulator |

|---|---|---|

| Heating Method | Direct heat via stovetop or flame | Induction heating with precise temperature control |

| Temperature Accuracy | Low - dependent on stove settings | High - accurate digital temperature control |

| Boiling Speed | Moderate - varies with stove power | Fast - efficient induction heating |

| Energy Efficiency | Moderate - heat loss common | High - targeted heat minimizes waste |

| Safety | Risk of burner-related burns or overboiling | Safer - automatic shutoff and controlled temperature |

| Cost | Low to moderate | High initial investment |

| Use Case | General boiling, soups, large-volume cooking | Precision cooking, sous vide, temperature-sensitive boiling |

Understanding Boiling: Traditional Stockpot vs Induction Thermal Circulator

Boiling water in a traditional stockpot relies on direct heat transfer from the stove, resulting in uneven temperature distribution. Induction thermal circulators utilize magnetic induction to heat water precisely and maintain a stable, uniform temperature throughout the pot. This technology enhances energy efficiency and ensures consistent boiling, ideal for professional or precise culinary applications.

Equipment Overview: Stockpot Features and Functionality

What are the key features and functionalities of a stockpot in boiling applications? A stockpot offers large capacity and robust construction, ideal for boiling large quantities of liquid evenly. Its compatibility with various heat sources and simple design ensures reliable performance in traditional cooking and food preparation tasks.

How Induction Thermal Circulators Work for Boiling

Induction thermal circulators generate heat through electromagnetic induction, rapidly transferring energy directly to the pot, which allows for precise temperature control during boiling. This method ensures uniform heat distribution, minimizing hotspots compared to traditional stockpots heated by an external flame or electric coil.

- Electromagnetic induction - Creates heat by inducing electrical currents within the cookware, providing efficient energy transfer.

- Precise temperature control - Maintains consistent boiling temperatures critical for delicate culinary applications.

- Uniform heat distribution - Circulates heat evenly throughout the liquid, preventing localized overheating and improving cooking consistency.

Temperature Precision: Which Method Is More Accurate?

Induction thermal circulators offer superior temperature precision compared to traditional stockpots, maintaining consistent heat within +-0.1degC for optimal boiling control. Stockpots rely on stovetop settings that fluctuate due to uneven heat distribution and slower response times, often causing temperature swings beyond +-5degC. Precise temperature regulation in induction thermal circulators enhances cooking outcomes by preventing overheating and ensuring stable boiling points.

Speed and Efficiency: Boiling Water Faster

Stockpots require direct heat and can take significantly longer to bring water to a boil compared to induction thermal circulators. Induction thermal circulators provide even, precise heat distribution, accelerating the boiling process efficiently.

Induction thermal circulators maintain consistent temperature control, reducing energy waste and ensuring rapid boiling. Stockpots often result in uneven heating, which can slow down the boiling time and impact overall efficiency. Choosing an induction thermal circulator optimizes both speed and energy use for boiling tasks.

Energy Consumption: Stockpot vs Induction Thermal Circulator

Induction thermal circulators offer precise temperature control, resulting in more efficient energy consumption compared to traditional stockpots. Stockpots often lose heat through convection and radiation, increasing overall energy usage during boiling processes.

- Induction thermal circulators use electromagnetic energy to heat water directly, minimizing heat loss and reducing energy waste.

- Stockpots rely on external heat sources such as gas or electric burners, causing greater thermal dispersion and higher energy consumption.

- Energy efficiency in boiling tasks is significantly improved when using induction thermal circulators, especially for long-duration cooking.

Safety Considerations in Boiling with Each Method

| Method | Safety Considerations |

|---|---|

| Stockpot | Risk of burns from exposed hot surfaces and boiling liquids is high; requires careful handling and stable placement to prevent spills. Steam exposure can cause scald injuries, and open flames pose fire hazards especially in kitchens lacking ventilation. |

| Induction Thermal Circulator | Encased heating element minimizes direct contact injuries, reducing burn risks significantly. Precise temperature control prevents overheating and boiling over, while automatic shutoff features enhance user safety. Requires compatible cookware but generally offers safer handling due to consistent and contained heat distribution. |

Culinary Applications: Best Uses for Stockpots and Induction Circulators

Stockpots are ideal for boiling large volumes of water or broth, making them perfect for soups, pasta, and stock preparations. Induction thermal circulators excel in precise temperature control, enhancing sous vide cooking and delicate boiling processes in culinary applications.

- Stockpot capacity - Typically ranges from 8 to 20 quarts, allowing for bulk cooking suitable for family meals or professional kitchens.

- Induction circulator precision - Maintains temperature within +-0.1degC, crucial for consistent cooking results and texture control.

- Heat distribution - Stockpots provide broad heat distribution ideal for rapid boiling, while induction circulators offer even temperature regulation for gentle simmering.

Choosing between stockpots and induction thermal circulators depends on the cooking method and desired temperature accuracy in culinary applications.

Maintenance and Cleaning: Ease of Use Comparison

Stockpots require regular manual cleaning to prevent residue buildup, often involving scrubbing and soaking to maintain optimal performance. Induction thermal circulators feature detachable and washable components that simplify maintenance and reduce downtime.

Cleaning a stockpot can be time-consuming due to its large size and material sensitivity, especially after prolonged boiling sessions. Induction thermal circulators are designed with corrosion-resistant surfaces and fewer crevices, allowing for quicker, more efficient cleaning routines.

Related Important Terms

Precision Induction Boiling

Precision induction boiling in stockpots offers rapid and even heat distribution, minimizing temperature fluctuations crucial for delicate boiling tasks. Induction thermal circulators enhance this control by maintaining consistent, precise temperatures, making them ideal for applications demanding exact thermal management over extended periods.

Circulative Heat Transfer

Stockpots provide direct conduction heating with limited heat distribution, resulting in uneven boiling and hotspots, while induction thermal circulators utilize magnetic fields to generate precise, uniform heat and continuous liquid circulation, enhancing circulative heat transfer efficiency and consistent temperature control. The circulative motion created by induction thermal circulators significantly accelerates heat transfer rates, reducing boiling times and improving energy efficiency compared to traditional stockpots.

Sous Vide Thermal Loop

Sous Vide Thermal Loop offers precise temperature control for boiling, maintaining consistent heat in a sealed environment, unlike a traditional stockpot which often results in temperature fluctuations. Its energy-efficient induction heating and continuous water circulation ensure even cooking, making it ideal for sous vide applications.

Distributed Boil Uniformity

Stockpots often provide uneven heat distribution leading to hot spots and inconsistent boil uniformity, while induction thermal circulators deliver precise temperature control with uniform heat distribution throughout the liquid. This advanced circulation technology ensures consistent boil rates and prevents localized overheating, enhancing cooking efficiency and food quality.

Edge-to-Edge Rolling Boil

A stockpot delivers an edge-to-edge rolling boil by evenly distributing high heat over its broad surface, achieving consistent vigorous bubbling suitable for large-volume cooking. In contrast, an induction thermal circulator uses precise temperature controls but may struggle to maintain a full rolling boil across the entire pot surface, making it ideal for gentle simmering rather than aggressive boiling.

PID-Controlled Boil

A stockpot relies on direct heat and manual monitoring, often causing uneven temperature distribution and inconsistent boiling results. In contrast, an induction thermal circulator with PID-controlled boil precisely maintains target temperatures by continuously adjusting heat input, ensuring uniform boiling and preventing overheating or scorching.

Magnetic Stir-Assisted Boiling

Magnetic stir-assisted boiling in stockpots enhances heat distribution and prevents localized overheating, while induction thermal circulators provide precise temperature control and consistent thermal circulation for more efficient boiling. Combining magnetic stirring with induction heating maximizes energy efficiency and uniform heat transfer during boiling processes.

Thermal Fluid Dynamics Propagation

Stockpots rely on direct conduction and natural convection to transfer heat, resulting in slower thermal fluid dynamics propagation and less uniform boiling. Induction thermal circulators use electromagnetic fields to generate rapid, consistent heat distribution and active fluid circulation, significantly enhancing thermal propagation efficiency during boiling.

Stockpot Convection Gradient

Stockpots create a convection gradient during boiling by heating from the base, causing hot water to rise and cooler water to descend, which promotes uneven temperature distribution. In contrast, induction thermal circulators maintain a uniform temperature by continuously circulating water, eliminating convection gradients for precise and consistent boiling.

Stockpot vs Induction thermal circulator for boiling. Infographic

cookingdiff.com

cookingdiff.com