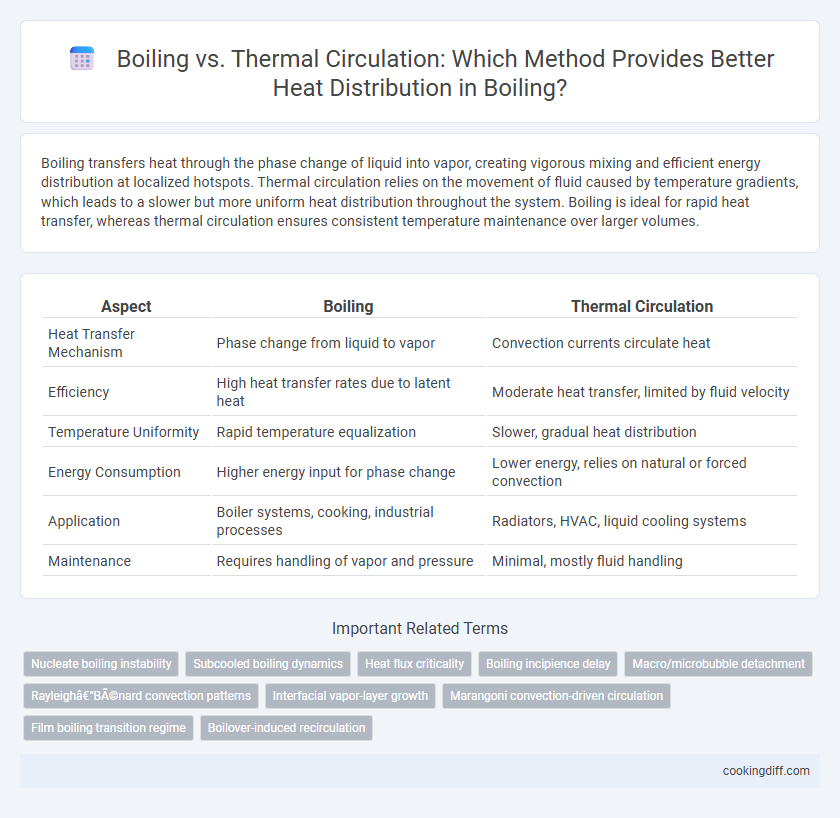

Boiling transfers heat through the phase change of liquid into vapor, creating vigorous mixing and efficient energy distribution at localized hotspots. Thermal circulation relies on the movement of fluid caused by temperature gradients, which leads to a slower but more uniform heat distribution throughout the system. Boiling is ideal for rapid heat transfer, whereas thermal circulation ensures consistent temperature maintenance over larger volumes.

Table of Comparison

| Aspect | Boiling | Thermal Circulation |

|---|---|---|

| Heat Transfer Mechanism | Phase change from liquid to vapor | Convection currents circulate heat |

| Efficiency | High heat transfer rates due to latent heat | Moderate heat transfer, limited by fluid velocity |

| Temperature Uniformity | Rapid temperature equalization | Slower, gradual heat distribution |

| Energy Consumption | Higher energy input for phase change | Lower energy, relies on natural or forced convection |

| Application | Boiler systems, cooking, industrial processes | Radiators, HVAC, liquid cooling systems |

| Maintenance | Requires handling of vapor and pressure | Minimal, mostly fluid handling |

Introduction: Understanding Heat Distribution in Cooking

Boiling involves heating water to its boiling point, creating steam and bubbles that directly transfer heat to food. Thermal circulation relies on the natural movement of heated fluids, distributing heat more evenly within a cooking vessel. Understanding the differences in these heat distribution methods is essential for optimizing cooking efficiency and food texture.

What is Boiling? Principles and Process

Boiling is the rapid vaporization of a liquid when its vapor pressure equals the atmospheric pressure, leading to the formation of bubbles throughout the liquid. This phase change efficiently transfers heat by converting liquid to vapor, enhancing heat distribution compared to thermal circulation.

- Vapor Pressure Equilibrium - Boiling occurs when a liquid's vapor pressure matches the surrounding atmospheric pressure, initiating bubble formation.

- Bubble Formation and Growth - Vapor bubbles form at nucleation sites and grow as heat energy converts liquid into vapor.

- Efficient Heat Transfer - The latent heat absorbed during boiling significantly enhances heat distribution throughout the liquid.

Exploring Thermal Circulation Methods

Thermal circulation methods enhance heat distribution by inducing fluid motion without phase change, contrasting with boiling where vaporization facilitates heat transfer. Exploring natural and forced convection techniques reveals varying efficiencies and applications in thermal management systems.

- Natural Convection - Heat transfer occurs as warmer fluid rises and cooler fluid descends, driven by density differences.

- Forced Convection - External devices like pumps or fans actively circulate fluid to improve heat distribution.

- Hybrid Systems - Combine natural and forced convection to optimize heat transfer in complex environments.

Thermal circulation offers a controlled, energy-efficient alternative to boiling for uniform heat distribution in many industrial processes.

Heat Transfer Mechanisms: Boiling vs. Thermal Circulation

Boiling transfers heat through the phase change of liquid to vapor, significantly enhancing thermal conductivity and energy transfer rates. Thermal circulation relies on fluid motion caused by temperature-induced density gradients to distribute heat without phase change.

- Boiling Heat Transfer - Involves vapor bubble formation that rapidly removes heat from the surface, increasing overall heat flux.

- Thermal Circulation Heat Transfer - Depends on convection currents formed by temperature differences, promoting continuous fluid movement.

- Efficiency Comparison - Boiling typically achieves higher heat transfer coefficients than thermal circulation due to latent heat absorption during phase change.

Temperature Uniformity: Comparing Boiling and Thermal Circulation

How does temperature uniformity compare between boiling and thermal circulation for heat distribution? Boiling creates localized hotspots due to phase change, resulting in less uniform temperature distribution. Thermal circulation promotes consistent heat transfer by evenly distributing temperature throughout the fluid medium.

Cooking Efficiency: Time, Energy, and Consistency

| Boiling | Rapid heat transfer by phase change, reducing cooking time and conserving energy through efficient heat use. |

| Thermal Circulation | Heat evenly distributes through fluid movement, providing consistent temperature but often requiring longer cooking times and higher energy consumption. |

| Cooking Efficiency | Boiling delivers faster results with lower energy input, while thermal circulation ensures uniform heat but may increase overall cooking duration and energy needed. |

Food Texture and Flavor Impact

Boiling rapidly transfers heat through direct contact with water, often leading to a uniform but sometimes overcooked texture in food. Thermal circulation gently distributes heat via convection currents, preserving delicate textures and enhancing flavor complexity by preventing nutrient loss. This method is especially effective for maintaining the integrity of vegetables and seafood, resulting in a more vibrant taste and better mouthfeel.

Equipment and Setup Differences

Boiling systems require boilers or heat exchangers capable of reaching and sustaining high temperatures to vaporize liquids, whereas thermal circulation setups use pumps and piping to circulate heated fluids without phase change. Boiling equipment typically includes robust pressure vessels and safety valves to manage steam generation, contrasting with thermal circulation systems that prioritize efficient flow control and insulation.

In boiling setups, the apparatus must withstand intense thermal stresses and manage steam pressure, demanding materials with high thermal conductivity and mechanical strength. Thermal circulation equipment focuses on maintaining steady fluid movement through heat exchangers and circulation loops, emphasizing system balance and temperature uniformity.

Safety Considerations in Boiling and Thermal Circulation

Boiling involves direct phase change which can lead to rapid temperature fluctuations and localized overheating, requiring careful monitoring to prevent risks such as burns or pressure build-up. Thermal circulation uses convective heat transfer, offering more uniform temperature distribution and reducing the likelihood of sudden hot spots or equipment failure.

Safety measures in boiling systems include pressure relief valves and automatic shut-off controls to manage steam pressure and prevent accidents. In thermal circulation, maintaining clean fluid pathways and monitoring pump function are crucial to avoid blockages or pump failure that could compromise safe heat transfer.

Related Important Terms

Nucleate boiling instability

Nucleate boiling instability occurs when vapor bubbles formed at heated surfaces fluctuate in size and detachment frequency, disrupting consistent heat transfer compared to steady thermal circulation. This instability reduces heat distribution efficiency by causing uneven surface temperatures and localized hotspots, unlike the more uniform heat transfer achieved through thermal circulation mechanisms.

Subcooled boiling dynamics

Subcooled boiling enhances heat distribution by generating vapor bubbles in a liquid below its saturation temperature, promoting intense thermal circulation due to bubble-induced turbulence and micro-convection. This process outperforms simple thermal circulation by increasing heat transfer coefficients and preventing hot spots through localized nucleate boiling dynamics.

Heat flux criticality

Boiling enhances heat flux significantly by utilizing phase change to transfer heat efficiently, surpassing the heat transfer rates achievable through thermal circulation alone. Critical heat flux marks the threshold where boiling transitions from nucleate to film boiling, causing a drastic drop in heat transfer efficiency and posing a risk of thermal damage.

Boiling incipience delay

Boiling incipience delay occurs when the temperature of the heating surface exceeds the bulk fluid temperature without immediate bubble formation, hindering efficient heat distribution compared to thermal circulation where fluid motion enhances heat transfer rapidly. This delay in nucleate boiling onset reduces overall thermal performance, emphasizing the need for optimized surface conditions to minimize incipience time and improve energy exchange.

Macro/microbubble detachment

Boiling enhances heat distribution through rapid microbubble detachment, which disrupts thermal boundary layers and increases local fluid mixing compared to thermal circulation that relies on slower and larger-scale macrobubble movements. Microbubble detachment during nucleate boiling significantly improves heat transfer efficiency by accelerating fluid renewal at the heated surface, outperforming the relatively weaker convective effects of macrobubble-induced thermal circulation.

Rayleigh–Bénard convection patterns

Boiling involves phase change heat transfer where vapor bubbles enhance thermal energy removal, while thermal circulation relies on Rayleigh-Benard convection patterns characterized by steady, hexagonal cell formations driving fluid motion due to buoyancy effects and temperature gradients. Rayleigh-Benard convection provides efficient, uniform heat distribution through fluid movement without phase change, contrasting the localized intense heat fluxes in boiling phenomena.

Interfacial vapor-layer growth

Interfacial vapor-layer growth during boiling creates localized temperature gradients that enhance heat transfer rates compared to thermal circulation, which relies primarily on bulk fluid motion for heat distribution. The dynamic formation and collapse of vapor layers generate micro-convection currents, disrupting thermal boundary layers more effectively than steady thermal circulation alone.

Marangoni convection-driven circulation

Boiling enhances heat distribution through nucleate bubble formation, while thermal circulation driven by Marangoni convection relies on surface tension gradients caused by temperature differences at the liquid-gas interface. Marangoni convection promotes efficient mass and heat transfer by inducing fluid motion without phase change, offering controlled heat flux management in microscale and low-gravity environments.

Film boiling transition regime

In the film boiling transition regime, heat distribution is dominated by the stable vapor layer that insulates the surface, significantly reducing thermal circulation and convective heat transfer efficiency. This vapor film disrupts direct liquid contact, causing a sharp increase in surface temperature and altering the dynamics compared to nucleate boiling where vigorous thermal circulation enhances heat transfer.

Boiling vs Thermal Circulation for heat distribution. Infographic

cookingdiff.com

cookingdiff.com