Braising relies on slow cooking with liquid at low, consistent temperatures to tenderize meats, but temperature control can vary depending on the heat source. Delta-T cooking focuses on maintaining a precise temperature difference between the cooking environment and the food, allowing for more accurate control and preventing overcooking. This method enhances temperature precision compared to traditional braising by ensuring even heat distribution and consistent internal cooking.

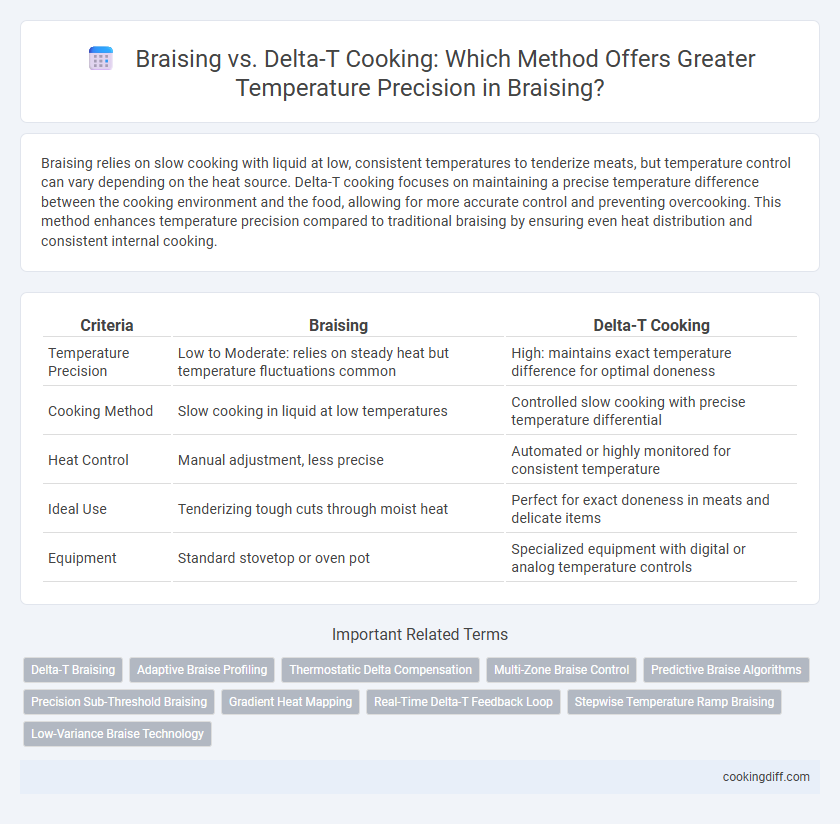

Table of Comparison

| Criteria | Braising | Delta-T Cooking |

|---|---|---|

| Temperature Precision | Low to Moderate: relies on steady heat but temperature fluctuations common | High: maintains exact temperature difference for optimal doneness |

| Cooking Method | Slow cooking in liquid at low temperatures | Controlled slow cooking with precise temperature differential |

| Heat Control | Manual adjustment, less precise | Automated or highly monitored for consistent temperature |

| Ideal Use | Tenderizing tough cuts through moist heat | Perfect for exact doneness in meats and delicate items |

| Equipment | Standard stovetop or oven pot | Specialized equipment with digital or analog temperature controls |

Introduction to Braising and Delta-T Cooking

| Braising is a cooking method that combines searing food at high temperatures and slow cooking it in liquid to achieve tender, flavorful results. Delta-T cooking involves precise temperature control by maintaining a small and consistent temperature difference between the cooking medium and the food, leading to more uniform cooking. The temperature precision in Delta-T cooking reduces moisture loss and optimizes texture, making it a modern alternative to traditional braising techniques. |

Understanding Braising: Traditional Slow Cooking

Braising is a traditional slow cooking method that combines moist heat and low temperatures to break down tough fibers in meat, ensuring tender and flavorful results. Delta-T cooking focuses on maintaining a precise temperature differential between the cooking medium and the food, optimizing heat transfer and preventing overcooking. Understanding braising emphasizes consistent low heat and moisture, contrasting with the precise thermal control that defines Delta-T techniques in culinary applications.

What Is Delta-T Cooking?

Delta-T cooking uses a controlled temperature difference between the cooking medium and the food, enabling precise temperature management. This method enhances tenderness and flavor by maintaining consistent heat transfer without overcooking.

- Delta-T Principle - Cooking relies on a steady, small temperature gap between the food and the surrounding liquid to optimize heat flow.

- Temperature Precision - Allows chefs to maintain exact target temperatures, improving consistency over traditional braising.

- Food Texture Benefits - Results in uniformly cooked, tender dishes by preventing temperature spikes common in conventional methods.

Temperature Precision: Why It Matters

Braising relies on steady, low heat to break down tough fibers slowly, requiring consistent temperature control to achieve tender results. Delta-T cooking employs a precise temperature differential between the cooking environment and the food, maintaining optimal heat transfer and preventing overcooking.

Temperature precision is crucial in braising to avoid drying out or undercooking ingredients, ensuring even texture and flavor development. Delta-T cooking enhances this control by regulating the exact temperature gradient, allowing for consistent and predictable doneness. This method minimizes moisture loss and preserves the integrity of delicate proteins, making it superior in maintaining optimal cooking conditions.

Techniques Compared: Braising vs Delta-T Methods

Braising uses a consistent low temperature with moisture to break down tough fibers in meat, relying on a stable heat environment. Delta-T cooking employs a precise temperature differential between the cooking medium and the target internal temperature for controlled, gentle cooking.

- Braising relies on a steady temperature near simmering point - maintaining a uniform heat facilitates collagen breakdown and tenderizes tougher cuts.

- Delta-T cooking controls the temperature gradient precisely - this allows gradual cooking that prevents overcooking and preserves moisture.

- Braising typically involves longer cooking times - while Delta-T methods optimize cooking duration by dynamically adjusting heat input based on temperature differences.

Equipment Requirements: Pots, Ovens, and Precision Tools

How do equipment requirements differ between braising and Delta-T cooking for temperature precision? Braising typically requires heavy, enameled cast iron pots and conventional ovens that maintain steady low heat. Delta-T cooking demands precise temperature control tools such as sous vide machines or slow cookers paired with digital thermometers for exact heat management.

Flavor Development and Texture Outcomes

Braising combines searing and slow cooking to develop deep, rich flavors and tenderize tough cuts through prolonged heat and moisture exposure. Delta-T cooking uses precise temperature control to gradually increase the food's internal temperature for consistent texture and enhanced flavor extraction.

- Flavor Development - Braising promotes complex Maillard reaction flavors from initial searing before slow simmering enhances savory depth.

- Texture Outcomes - Braising breaks down collagen into gelatin, creating tender, succulent meat with moist textures.

- Precision Control - Delta-T cooking maintains steady, incremental temperature rises to avoid overcooking and preserve desired texture.

Delta-T cooking offers superior temperature precision while braising excels in flavor complexity through traditional cooking methods.

Energy Efficiency and Cooking Times

Braising typically involves cooking at a constant low temperature, which can lead to longer cooking times and higher energy consumption compared to Delta-T cooking. Delta-T cooking adjusts the temperature difference between the cooking medium and the food, improving temperature precision and reducing energy waste.

Energy efficiency in Delta-T cooking is enhanced by maintaining optimal heat transfer, allowing foods to cook faster while preserving moisture and texture. This method significantly shortens cooking times compared to traditional braising, resulting in lower overall energy usage.

Best Applications: When to Use Each Method

Braising excels in tenderizing tough cuts of meat through slow, moist heat, ideal for stews and pot roasts that require low, consistent temperatures around 160-180degF (71-82degC). Delta-T cooking offers precise temperature control by maintaining a consistent difference between the food's core and the cooking environment, making it perfect for delicate proteins and vegetables that need exact doneness without overcooking.

Choose braising when aiming for rich flavors and breakdown of collagen in tougher ingredients, benefiting from long cook times with liquid. Delta-T suits chefs seeking consistent texture and moisture retention in premium cuts or components sensitive to thermal shock, optimizing cooking efficiency and product quality.

Related Important Terms

Delta-T Braising

Delta-T braising enhances temperature precision by maintaining a constant temperature differential between the cooking medium and the meat, resulting in more even heat penetration and consistent texture. Unlike traditional braising, which relies on a fixed liquid temperature, Delta-T controls the temperature gradient, reducing overcooking and improving moisture retention.

Adaptive Braise Profiling

Adaptive Braise Profiling enhances braising by dynamically adjusting temperature based on precise Delta-T cooking principles, ensuring consistent, tender results. This method maintains optimal heat gradients to prevent overcooking and preserve moisture, outperforming traditional braising techniques reliant on static temperature settings.

Thermostatic Delta Compensation

Braising requires precise temperature control to break down collagen and tenderize meat, which Thermostatic Delta Compensation in Delta-T cooking achieves by maintaining a consistent temperature differential between the food and the cooking environment. This method minimizes temperature fluctuations, enhancing moisture retention and ensuring even cooking compared to traditional braising techniques that rely on constant external temperatures.

Multi-Zone Braise Control

Multi-Zone Braise Control in braising offers precise temperature management across different sections of the cooking vessel, outperforming Delta-T cooking's reliance on constant temperature differentials. This advanced control system ensures optimal heat distribution, enhancing texture and flavor development by maintaining target temperatures in each zone for consistent, high-quality results.

Predictive Braise Algorithms

Predictive Braise Algorithms enhance temperature precision in braising by continuously adjusting heat based on food thermal properties, contrasting with the steady Delta-T method that maintains a fixed temperature difference. This dynamic control optimizes moisture retention and texture by anticipating temperature gradients within the food during the braising process.

Precision Sub-Threshold Braising

Precision Sub-Threshold Braising offers enhanced temperature control by maintaining heat just below the boiling point, reducing the risk of overcooking while allowing gradual collagen breakdown for tender results. Compared to Delta-T cooking, which adjusts temperature based on the difference between the food's core and environment, precision sub-threshold braising provides a more stable and consistent temperature environment optimized for delicate meat textures.

Gradient Heat Mapping

Braising relies on consistent low and slow heat, creating a uniform temperature environment, while Delta-T cooking utilizes gradient heat mapping to maintain a precise temperature difference between the cooking medium and the food, optimizing thermal transfer efficiency. Gradient heat mapping in Delta-T cooking allows for more accurate control of internal temperatures, reducing the risk of overcooking compared to the more generalized heat application in traditional braising methods.

Real-Time Delta-T Feedback Loop

Braising leverages low, steady temperatures to break down tough cuts of meat, while Delta-T cooking employs a real-time Delta-T feedback loop to maintain precise temperature differentials between the cooking medium and the food, ensuring even heat transfer and optimal doneness. This dynamic control in Delta-T cooking prevents overcooking and enhances texture by continuously adjusting heat based on actual temperature changes rather than fixed set points.

Stepwise Temperature Ramp Braising

Stepwise temperature ramp braising enhances temperature precision by gradually increasing heat, allowing connective tissues to break down evenly and retain moisture better than traditional Delta-T cooking. This method improves texture and flavor by maintaining consistent, controlled increments, optimizing heat transfer and minimizing overcooking risks.

Braising vs Delta-T cooking for temperature precision. Infographic

cookingdiff.com

cookingdiff.com