Braising and pressure cooking both tenderize meat by breaking down collagen, but braising uses low, slow heat in liquid, resulting in rich, deep flavors and a delicate texture. Pressure cooking achieves tenderness much faster by using high steam pressure, making it ideal for busy cooks who need quick results without sacrificing moisture. While braising enhances complexity through gradual cooking, pressure cooking offers convenience and efficiency, delivering tender meat in a fraction of the time.

Table of Comparison

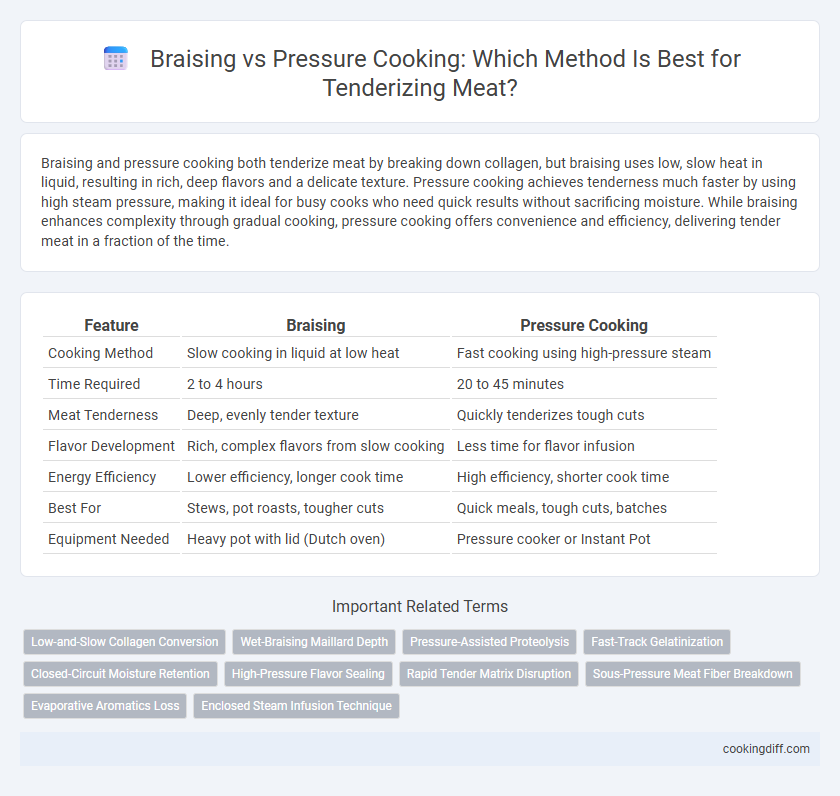

| Feature | Braising | Pressure Cooking |

|---|---|---|

| Cooking Method | Slow cooking in liquid at low heat | Fast cooking using high-pressure steam |

| Time Required | 2 to 4 hours | 20 to 45 minutes |

| Meat Tenderness | Deep, evenly tender texture | Quickly tenderizes tough cuts |

| Flavor Development | Rich, complex flavors from slow cooking | Less time for flavor infusion |

| Energy Efficiency | Lower efficiency, longer cook time | High efficiency, shorter cook time |

| Best For | Stews, pot roasts, tougher cuts | Quick meals, tough cuts, batches |

| Equipment Needed | Heavy pot with lid (Dutch oven) | Pressure cooker or Instant Pot |

Introduction to Braising and Pressure Cooking

| Braising | Braising involves cooking meat slowly in a small amount of liquid at low temperatures, allowing collagen breakdown to create tender, flavorful results. This method combines moist and dry heat, typically performed in a covered pot in the oven or on a stovetop. Braising is ideal for tougher cuts such as brisket, chuck, and short ribs, resulting in succulent texture through prolonged cooking. |

| Pressure Cooking | Pressure cooking uses high-pressure steam to cook meat quickly while breaking down connective tissues efficiently. By increasing pressure, temperatures rise above boiling point, significantly reducing cooking times compared to braising. This technique preserves moisture and enhances tenderness, making it suitable for similar tough cuts but with faster turnaround. |

How Braising Works for Tenderizing Meat

Braising tenderizes meat by cooking it slowly at a low temperature in a small amount of liquid, which breaks down tough collagen fibers into gelatin, resulting in a tender and flavorful texture. The prolonged moisture and heat penetration allow connective tissues to dissolve without drying out the meat.

This method contrasts with pressure cooking, where high pressure and temperature cook meat rapidly but can sometimes lead to a different texture. Braising is ideal for cuts like brisket, chuck, and shank that require gentle, slow cooking to become tender.

Pressure Cooking: The Science Behind Tenderization

Pressure cooking tenderizes meat by using high-pressure steam to increase the boiling point of water, allowing temperatures to rise above 212degF (100degC). This accelerated heat breaks down collagen and connective tissues faster than traditional methods, resulting in meat that is tender and juicy in a fraction of the time.

The sealed environment of a pressure cooker retains moisture and intensifies heat, ensuring even cooking and preventing drying out. Scientific studies show that pressure cooking can reduce cooking times by up to 70% while preserving flavor and nutritional content.

Key Differences Between Braising and Pressure Cooking

Braising involves slow cooking meat in a tightly covered pot with a small amount of liquid at low temperatures, enhancing flavor through gradual heat exposure. Pressure cooking uses high-pressure steam to rapidly cook meat, significantly reducing tenderizing time while preserving moisture.

- Cooking Time - Braising requires several hours, while pressure cooking reduces the process to under an hour.

- Temperature and Pressure - Braising uses low simmering temperatures, whereas pressure cooking operates at high pressure and elevated temperatures.

- Texture and Flavor Development - Braising develops deeper, richer flavors and tenderizes meat gradually; pressure cooking produces tender meat quickly but may yield less complex flavors.

Flavor Development: Braising vs Pressure Cooking

Braising enhances flavor development through slow, moist heat that allows collagen to break down gradually, resulting in rich, deep-tasting meat with complex caramelization. Pressure cooking tenderizes meat faster but may limit the Maillard reaction, producing less pronounced flavors compared to traditional braising.

Braising's extended cooking time promotes the fusion of spices, herbs, and meat juices, creating a robust, layered taste profile. Pressure cooking traps steam to tenderize meat quickly, preserving its natural flavors but often sacrificing the rich browning effects. Choosing between these methods depends on whether depth of flavor or speed of cooking is prioritized.

Texture Comparison: Which Method Yields More Tender Meat?

Braising slowly cooks meat in liquid at low temperatures, allowing collagen to break down gradually, resulting in a tender, moist texture with rich, developed flavors. Pressure cooking uses high pressure and temperature to rapidly tenderize meat, often producing a uniformly soft texture but sometimes at the expense of depth in flavor. For the most tender meat with complex texture, braising generally yields superior results, while pressure cooking excels in speed and convenience.

Time and Efficiency: Braising Compared to Pressure Cooking

Braising typically requires several hours of slow cooking at low temperatures to break down tough meat fibers, resulting in tender, flavorful dishes. Pressure cooking drastically reduces cooking time by using high pressure and temperature, making it a more efficient method for tenderizing meat.

- Time Efficiency - Braising can take 2 to 4 hours, whereas pressure cooking usually completes the process in 30 to 60 minutes.

- Heat Application - Braising uses gentle, indirect heat while pressure cooking applies intense heat and pressure to speed up tenderizing.

- Flavor Development - Braising promotes deeper flavor infusion through slow simmering, which is less pronounced in pressure cooking.

Choosing between braising and pressure cooking depends on balancing desired tenderness, flavor depth, and available time.

Suitable Cuts of Meat for Braising and Pressure Cooking

Braising is ideal for tougher, collagen-rich cuts like chuck roast, brisket, and short ribs that benefit from slow, moist heat to break down connective tissues. Pressure cooking tenderizes similar cuts faster by using high pressure and steam, making it suitable for brisket, shank, and pork shoulder. Both methods excel with well-marbled, tough cuts that require extended cooking to become tender and flavorful.

Nutrient Retention in Braised vs Pressure Cooked Meat

Braising preserves more water-soluble vitamins in meat due to its lower cooking temperature and longer cooking time. Pressure cooking, while faster, can cause greater nutrient loss because of the high heat and pressure applied during the process.

- Braising retains vitamins - Slow cooking at moderate heat helps preserve B vitamins and antioxidant levels in meat.

- Pressure cooking reduces nutrients - High pressure and temperature accelerate nutrient degradation, especially of heat-sensitive vitamins.

- Mineral retention is similar - Both methods generally maintain minerals like iron and zinc effectively despite differences in heat exposure.

Related Important Terms

Low-and-Slow Collagen Conversion

Braising utilizes low-and-slow collagen conversion by cooking meat at a low temperature over an extended period, breaking down tough connective tissues into gelatin that enhances tenderness and moisture retention. Pressure cooking achieves collagen breakdown more rapidly through high heat and pressure, but the slower process of braising allows for more even gelatinization and deeper flavor development in the meat.

Wet-Braising Maillard Depth

Wet-braising develops Maillard reactions more gradually, enhancing deep, complex flavors and tenderizing meat through slow cooking in liquid, while pressure cooking accelerates tenderization but often produces less Maillard depth due to shorter exposure and higher moisture. For recipes seeking rich, caramelized crusts and nuanced savory profiles, wet-braising remains superior in flavor development despite longer cooking times.

Pressure-Assisted Proteolysis

Pressure cooking accelerates tenderizing meat by enhancing pressure-assisted proteolysis, which breaks down collagen and muscle fibers more rapidly than traditional braising methods. This intensified enzymatic activity under high pressure significantly reduces cooking time while maintaining moisture and flavor in tougher cuts.

Fast-Track Gelatinization

Braising slowly converts collagen into gelatin through prolonged low-temperature cooking, tenderizing meat by breaking down connective tissues over hours. Pressure cooking accelerates gelatinization by applying high heat and pressure, reducing cooking time significantly while achieving comparable tenderness.

Closed-Circuit Moisture Retention

Braising uses a closed-circuit method where meat is slowly cooked in a small amount of liquid, allowing natural juices to circulate and retain moisture, resulting in tender, flavorful cuts. Pressure cooking creates a sealed environment that traps steam and moisture rapidly, but the intense pressure can sometimes reduce moisture retention compared to the gentle simmering process in braising.

High-Pressure Flavor Sealing

Braising slowly tenderizes meat by breaking down collagen through low-temperature, moist heat, enhancing rich, deep flavors over time. Pressure cooking accelerates this process using high-pressure steam that seals in juices and intensifies flavor, delivering tender and flavorful meat in a fraction of the time.

Rapid Tender Matrix Disruption

Braising slowly breaks down collagen in meat by cooking it at low temperatures over an extended period, enabling gradual tender matrix disruption that enhances texture and flavor. Pressure cooking accelerates this process by using high pressure and heat to rapidly denature proteins and dissolve connective tissues, resulting in faster tenderization without sacrificing moisture retention.

Sous-Pressure Meat Fiber Breakdown

Braising breaks down meat fibers slowly through low, moist heat over extended cooking times, resulting in tender, flavorful cuts. Sous-pressure cooking accelerates this process by combining pressure and precise temperature control, enhancing collagen dissolution and fiber breakdown for faster and equally tender results.

Evaporative Aromatics Loss

Braising relies on slow cooking with evaporative heat, which enhances flavor through gradual reduction but results in some loss of volatile aromatics due to steam evaporation. Pressure cooking, by sealing the cooking environment, minimizes evaporative aromatics loss, preserving more intense and concentrated meat flavors while tenderizing faster.

Braising vs Pressure Cooking for Tenderizing Meat Infographic

cookingdiff.com

cookingdiff.com