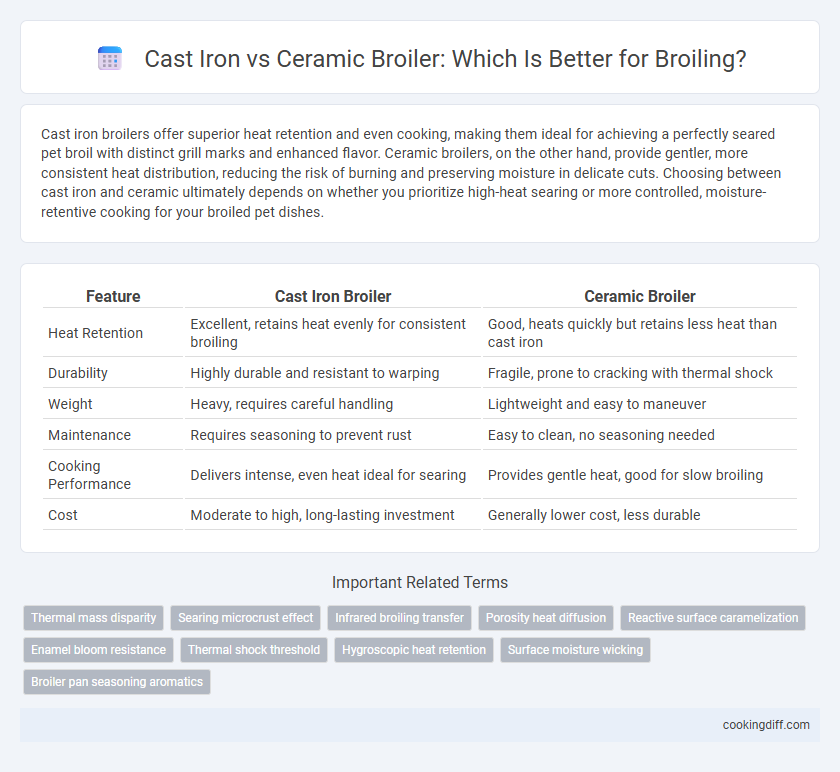

Cast iron broilers offer superior heat retention and even cooking, making them ideal for achieving a perfectly seared pet broil with distinct grill marks and enhanced flavor. Ceramic broilers, on the other hand, provide gentler, more consistent heat distribution, reducing the risk of burning and preserving moisture in delicate cuts. Choosing between cast iron and ceramic ultimately depends on whether you prioritize high-heat searing or more controlled, moisture-retentive cooking for your broiled pet dishes.

Table of Comparison

| Feature | Cast Iron Broiler | Ceramic Broiler |

|---|---|---|

| Heat Retention | Excellent, retains heat evenly for consistent broiling | Good, heats quickly but retains less heat than cast iron |

| Durability | Highly durable and resistant to warping | Fragile, prone to cracking with thermal shock |

| Weight | Heavy, requires careful handling | Lightweight and easy to maneuver |

| Maintenance | Requires seasoning to prevent rust | Easy to clean, no seasoning needed |

| Cooking Performance | Delivers intense, even heat ideal for searing | Provides gentle heat, good for slow broiling |

| Cost | Moderate to high, long-lasting investment | Generally lower cost, less durable |

Introduction to Broiling: Cast Iron vs Ceramic Broilers

Broiling is a high-heat cooking method that sears food quickly, ideal for achieving a crispy exterior and juicy interior. Cast iron broilers offer superior heat retention and even distribution, making them efficient for consistent cooking results. Ceramic broilers heat up rapidly and provide a non-stick surface, but may not retain heat as long as cast iron alternatives.

Material Composition: Cast Iron and Ceramic Broilers

Cast iron broilers are known for their exceptional heat retention and even heat distribution, making them ideal for achieving a consistent sear on meats. Their dense material composition allows for high-temperature broiling that locks in moisture and flavor efficiently.

Ceramic broilers, composed of clay-based materials, provide superior heat insulation and tend to distribute heat more gradually. This material composition reduces the risk of hot spots and allows for a gentler cooking process, preserving the natural texture of delicate foods.

Heat Distribution and Retention Comparison

Cast iron broilers excel in heat retention, maintaining a consistent high temperature ideal for searing meats and achieving even browning. Ceramic broilers provide more uniform heat distribution across the cooking surface, reducing hot spots and allowing for precise temperature control. While cast iron's durability supports intense heat, ceramic broilers offer superior thermal insulation, which contributes to energy efficiency during broiling.

Performance Under High Temperatures

Cast iron broilers excel in high-temperature retention, providing consistent and even heat ideal for searing meats. Ceramic broilers offer rapid heat buildup but can be prone to thermal shock when exposed to sudden temperature changes.

- Heat Retention - Cast iron maintains steady heat longer, ensuring uniform cooking.

- Heat Distribution - Ceramic provides quick heat spread but may develop hotspots over time.

- Durability - Cast iron withstands frequent temperature fluctuations without damage, unlike ceramic.

Flavor Enhancement in Broiling

How does the choice between cast iron and ceramic broilers impact flavor enhancement in broiling? Cast iron broilers excel at retaining and evenly distributing high heat, creating a superior sear that intensifies the natural flavors of meat and vegetables. Ceramic broilers offer gentler, more uniform heat that preserves moisture but may result in less pronounced caramelization and flavor development.

Durability and Longevity: Which Lasts Longer?

Cast iron broilers offer superior durability due to their dense, resilient material that resists warping and can withstand high temperatures over extended use. Ceramic broilers, while efficient in heat retention, are more prone to cracking or chipping, which can compromise their lifespan.

Longevity of cast iron broilers often exceeds decades with proper seasoning and maintenance, making them a long-term investment. Ceramic broilers require careful handling and may need replacement sooner in demanding cooking environments, impacting their overall durability.

Ease of Cleaning and Maintenance

Cast iron broilers require thorough cleaning and seasoning to prevent rusting, making maintenance more labor-intensive. Ceramic broilers offer a non-stick surface that simplifies cleaning and reduces the need for special care.

- Durability - Cast iron is highly durable but demands seasoning and careful drying to maintain its surface.

- Non-stick surface - Ceramic coatings resist food sticking, allowing easier cleanup after broiling.

- Maintenance frequency - Cast iron needs regular upkeep while ceramic broilers require less frequent maintenance.

Ceramic broilers provide a more user-friendly cleaning experience compared to cast iron models.

Safety Considerations for Home Broiling

Cast iron broilers offer excellent heat retention but require careful handling due to their heavy weight and high surface temperature, increasing the risk of burns in home kitchens. Ceramic broilers provide a safer alternative with lower heat conductivity on exterior surfaces, reducing accidental contact injuries during broiling.

When broiling at home, ensure proper ventilation and use heat-resistant gloves regardless of broiler type to prevent burns and respiratory irritation from smoke. Ceramic broilers are less likely to crack under thermal shock, making them safer for frequent use, while cast iron may require seasoning to avoid rust that could compromise safety. Both types demand regular maintenance to avoid buildup of food residues that can ignite and cause kitchen fires.

Cost Analysis: Cast Iron vs Ceramic Broilers

| Broiler Type | Initial Cost | Durability | Maintenance | Heat Efficiency |

|---|---|---|---|---|

| Cast Iron Broiler | $40 - $100 | Exceptional, often lasts decades | Requires seasoning and rust prevention | High heat retention for even broiling |

| Ceramic Broiler | $80 - $150 | Moderate, prone to cracking | Needs gentle cleaning and careful handling | Excellent radiant heat, faster preheating |

Related Important Terms

Thermal mass disparity

Cast iron broilers offer superior thermal mass, retaining and distributing heat evenly for consistent broiling results, while ceramic broilers have lower thermal mass, leading to faster heating but less stable temperature control. The significant thermal mass disparity affects cooking performance, with cast iron ideal for high-heat, steady broiling and ceramic better suited for quick, less intensive heat applications.

Searing microcrust effect

Cast iron broilers excel in creating a superior searing microcrust effect due to their excellent heat retention and even distribution, which allows sustained high temperatures essential for perfect browning. Ceramic broilers, while offering gentler heat, often lack the intense surface temperature needed to develop the same deeply caramelized, crispy texture characteristic of cast iron searing.

Infrared broiling transfer

Cast iron broilers excel in infrared heat transfer due to their dense material, providing consistent high temperatures and superior searing capabilities. Ceramic broilers offer efficient infrared radiation with faster heat-up times and even distribution, but may lack the intense heat retention of cast iron necessary for optimal broiling performance.

Porosity heat diffusion

Cast iron broilers offer superior heat retention and even diffusion due to their dense, less porous structure, ensuring consistent high-temperature cooking essential for perfect broiling. Ceramic broilers, with their more porous composition, tend to have uneven heat distribution and slower heat conduction, which can result in less efficient broiling performance.

Reactive surface caramelization

Cast iron broilers excel in reactive surface caramelization due to their superior heat retention and even distribution, which promotes intense Maillard reactions and deeper crust formation on foods. Ceramic broilers, while offering non-reactive and smoother surfaces, tend to provide less effective caramelization because their heat transfer is less consistent and surface interactions are minimal.

Enamel bloom resistance

Cast iron broilers offer superior enamel bloom resistance compared to ceramic broilers, as their dense structure withstands high heat cycles without cracking or discoloration. Ceramic broilers, while excellent at heat distribution, are more prone to enamel bloom deterioration due to thermal shock and surface wear over time.

Thermal shock threshold

Cast iron broilers have a higher thermal shock threshold due to their dense, durable material, allowing rapid temperature changes without cracking, whereas ceramic broilers are more prone to thermal shock damage because of their brittle nature. This makes cast iron broilers more reliable for intense broiling compared to ceramic options.

Hygroscopic heat retention

Cast iron broilers excel in hygroscopic heat retention due to their dense, porous structure, allowing them to maintain and evenly distribute high temperatures for superior searing and browning. Ceramic broilers, while offering rapid heat absorption, tend to lose heat more quickly and provide less consistent temperature retention during the broiling process.

Surface moisture wicking

Cast iron broilers excel at surface moisture wicking due to their dense, porous structure, which absorbs and redistributes juices, resulting in a well-seared, caramelized exterior. Ceramic broilers maintain moisture by providing even heat distribution but tend to trap surface moisture, often causing less crispy, steamed textures during broiling.

Cast iron broiler vs ceramic broiler for broiling. Infographic

cookingdiff.com

cookingdiff.com