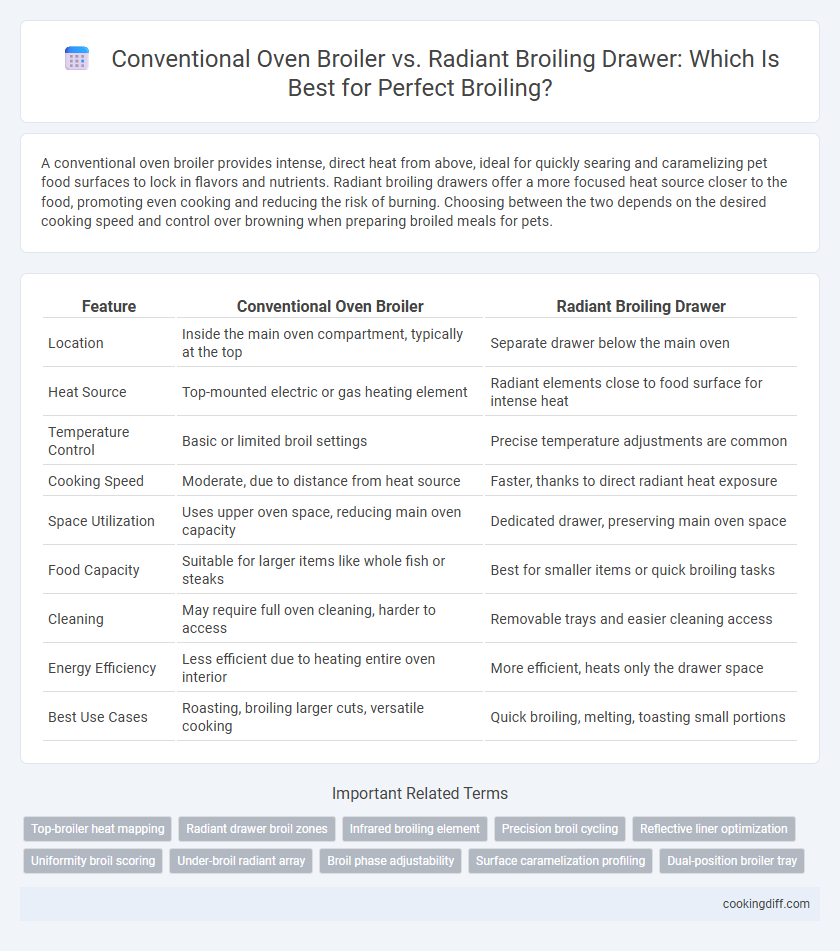

A conventional oven broiler provides intense, direct heat from above, ideal for quickly searing and caramelizing pet food surfaces to lock in flavors and nutrients. Radiant broiling drawers offer a more focused heat source closer to the food, promoting even cooking and reducing the risk of burning. Choosing between the two depends on the desired cooking speed and control over browning when preparing broiled meals for pets.

Table of Comparison

| Feature | Conventional Oven Broiler | Radiant Broiling Drawer |

|---|---|---|

| Location | Inside the main oven compartment, typically at the top | Separate drawer below the main oven |

| Heat Source | Top-mounted electric or gas heating element | Radiant elements close to food surface for intense heat |

| Temperature Control | Basic or limited broil settings | Precise temperature adjustments are common |

| Cooking Speed | Moderate, due to distance from heat source | Faster, thanks to direct radiant heat exposure |

| Space Utilization | Uses upper oven space, reducing main oven capacity | Dedicated drawer, preserving main oven space |

| Food Capacity | Suitable for larger items like whole fish or steaks | Best for smaller items or quick broiling tasks |

| Cleaning | May require full oven cleaning, harder to access | Removable trays and easier cleaning access |

| Energy Efficiency | Less efficient due to heating entire oven interior | More efficient, heats only the drawer space |

| Best Use Cases | Roasting, broiling larger cuts, versatile cooking | Quick broiling, melting, toasting small portions |

Introduction to Broiling: Methods and Technology

Broiling uses intense radiant heat to cook food quickly, typically from above the food surface. Conventional oven broilers and radiant broiling drawers represent two primary methods, differing in heat source location and intensity control.

- Conventional Oven Broiler - Positioned at the top of the oven, it provides broad, even heat ideal for thick cuts and charred finishes.

- Radiant Broiling Drawer - Located below the main oven cavity, it delivers direct, concentrated heat with rapid temperature adjustments.

- Heat Source Technology - Conventional broilers generally use electric coils or gas flames, while broiling drawers utilize infrared radiant elements for efficient energy transfer.

What is a Conventional Oven Broiler?

A conventional oven broiler is located at the top of a standard oven and uses radiant heat to cook food quickly by exposing it directly to high temperatures. It is designed for tasks such as searing steaks, melting cheese, or browning casseroles, providing intense, focused heat from above. Unlike a radiant broiling drawer, which is a separate compartment with a dedicated heat source, the conventional oven broiler shares the oven cavity and heating elements, making it suitable for versatile cooking needs.

Understanding Radiant Broiling Drawers

Radiant broiling drawers offer direct, intense heat from a radiant heating element located close to the food, providing faster and more even cooking compared to conventional oven broilers. These drawers are designed for efficient heat distribution and often produce better caramelization and crisping effects.

- Direct Heat Source - Radiant broiling drawers use a dedicated radiant heating element positioned near the food for immediate high temperatures.

- Even Cooking - The placement and design ensure uniform heat distribution, reducing hot spots common in conventional ovens.

- Improved Browning - Radiant heat enhances surface caramelization, resulting in superior texture and flavor development.

Understanding these features helps optimize broiling results by choosing the right method for your cooking needs.

Key Differences in Heat Distribution

Conventional oven broilers deliver heat from a top-mounted element, providing concentrated, high-intensity heat ideal for searing and caramelizing. Radiant broiling drawers emit heat from a lower, more enclosed source, offering more even temperature distribution with less risk of burning.

- Heat Source Location - Conventional broilers heat from above, while radiant broiling drawers heat from below or around the food.

- Heat Intensity - Conventional broilers typically have higher direct heat, creating faster surface browning.

- Cooking Uniformity - Radiant broiling drawers promote more consistent heat spreading for even cooking results.

Temperature Control and Precision

How does temperature control differ between a conventional oven broiler and a radiant broiling drawer? Conventional oven broilers often have less precise temperature settings, relying on a single high-heat element that can fluctuate. Radiant broiling drawers provide more accurate temperature control with adjustable settings, enabling consistent and even cooking results.

Cooking Times: Speed and Efficiency Compared

Conventional oven broilers typically have longer cooking times due to their higher placement within the oven, which results in less direct heat contact with the food. Radiant broiling drawers, positioned closer to the heating element, deliver more intense and even heat, significantly reducing cooking times.

With radiant broiling drawers, food cooks faster and more uniformly, improving efficiency for meals that require quick, high-heat exposure. Conventional broilers may require preheating and careful monitoring to avoid uneven cooking or burning, making them less time-efficient overall.

Browning and Texture Outcomes

Conventional oven broilers provide intense, direct heat from above, producing even browning and a classic crisp texture ideal for meats and vegetables. Radiant broiling drawers deliver focused heat that enhances caramelization while maintaining moisture, resulting in a tender yet flavorful finish.

Broiling with a conventional oven often yields a more consistent crust due to uniform heat distribution, perfect for achieving a desirable Maillard reaction. Radiant broiling drawers excel at quick, high-temperature searing that locks in juiciness and offers greater control over texture variations. Both methods influence browning intensity and surface texture, with radiant broilers typically producing a slightly softer interior and a rich, caramelized exterior.

Energy Consumption and Cost Efficiency

Conventional oven broilers consume more energy as they heat the entire oven cavity, leading to higher electricity usage and increased operational costs. Radiant broiling drawers target heat directly onto the food surface, reducing energy consumption by up to 30% compared to traditional oven broilers.

Cost efficiency improves with radiant broiling drawers due to shorter cooking times and focused heat delivery, lowering overall energy bills. Conventional oven broilers often require longer preheating periods, which contributes to increased energy expenditure and less economical cooking.

Cleaning, Maintenance, and Durability

Conventional oven broilers typically require frequent cleaning of the oven cavity and broiler pan to prevent grease buildup, which can affect performance and safety. Radiant broiling drawers feature removable trays that simplify cleaning and often have coatings that resist food sticking, enhancing durability. Both systems demand regular maintenance, but radiant broiling drawers generally offer longer-lasting components due to their specialized design focused on heat distribution and containment.

Related Important Terms

Top-broiler heat mapping

Conventional oven broilers distribute heat from a top heating element, creating uneven temperature zones that often result in hot and cool spots, affecting consistent cooking performance. Radiant broiling drawers utilize an infrared heat source positioned closer to the food, delivering more uniform top-broiler heat mapping and faster, more controlled browning.

Radiant drawer broil zones

Radiant broiling drawers feature distinct broil zones that provide concentrated, high-intensity heat directly from infrared elements, ensuring even cooking and superior browning compared to conventional oven broilers. These zoned designs allow precise temperature control and targeted heat distribution, optimizing the broiling process for different food types and thicknesses.

Infrared broiling element

Infrared broiling elements in radiant broiling drawers provide more intense and evenly distributed heat compared to conventional oven broilers, resulting in faster cooking times and superior searing. These elements emit high-energy infrared waves that penetrate food visibly more efficiently than traditional radiant heat sources in standard oven broilers.

Precision broil cycling

Conventional oven broilers often use cycling elements that fluctuate between high and low heat, leading to inconsistent temperature control during broiling. Radiant broiling drawers, equipped with precision broil cycling technology, maintain a steady, high-intensity radiant heat for more even cooking and better crust development on foods.

Reflective liner optimization

Conventional oven broilers typically use a reflective liner designed to maximize heat distribution by reflecting infrared radiation evenly across the food surface, enhancing browning and searing efficiency. Radiant broiling drawers often incorporate advanced reflective materials and positioning to intensify and concentrate heat directly from the element, resulting in faster cooking times and more precise temperature control.

Uniformity broil scoring

Conventional oven broilers typically provide uneven heat distribution due to their top-mounted heating elements, resulting in variable broil uniformity scores often below 75%. Radiant broiling drawers utilize specialized infrared elements positioned close to the food, achieving superior uniformity scores above 85% by delivering consistent, even heat across the cooking surface.

Under-broil radiant array

Under-broil radiant arrays in conventional oven broilers emit intense, direct infrared heat from above, enabling rapid surface searing and caramelization, while radiant broiling drawers offer more evenly distributed heat that reduces flare-ups and provides consistent cooking results. Radiant broiling drawers typically feature an array of infrared elements positioned below the food, creating a gentler under-broil environment ideal for delicate items and precise temperature control.

Broil phase adjustability

Conventional oven broilers typically offer limited broil phase adjustability, often restricted to preset high or low settings, which can affect precise temperature control during cooking. Radiant broiling drawers provide enhanced broil phase adjustability through adjustable heat intensity and customizable broiling cycles, enabling more consistent and tailored results for different types of food.

Surface caramelization profiling

Conventional oven broilers deliver intense, direct heat from the top element, creating a robust surface caramelization characterized by deep browning and crisp crusts. Radiant broiling drawers utilize infrared heat, producing even surface caramelization with precise temperature control, resulting in consistent browning and enhanced flavor profiles.

Conventional oven broiler vs radiant broiling drawer for broiling. Infographic

cookingdiff.com

cookingdiff.com