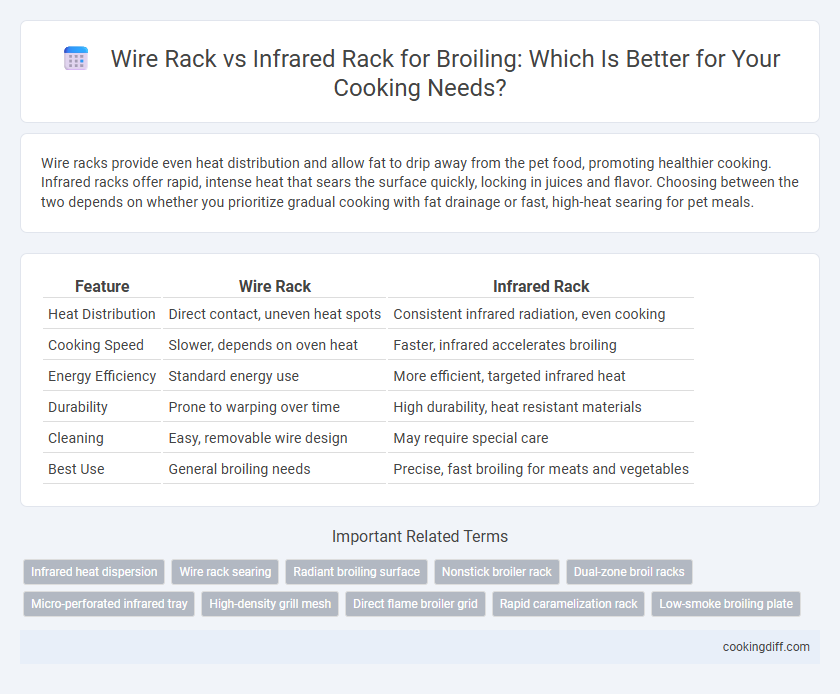

Wire racks provide even heat distribution and allow fat to drip away from the pet food, promoting healthier cooking. Infrared racks offer rapid, intense heat that sears the surface quickly, locking in juices and flavor. Choosing between the two depends on whether you prioritize gradual cooking with fat drainage or fast, high-heat searing for pet meals.

Table of Comparison

| Feature | Wire Rack | Infrared Rack |

|---|---|---|

| Heat Distribution | Direct contact, uneven heat spots | Consistent infrared radiation, even cooking |

| Cooking Speed | Slower, depends on oven heat | Faster, infrared accelerates broiling |

| Energy Efficiency | Standard energy use | More efficient, targeted infrared heat |

| Durability | Prone to warping over time | High durability, heat resistant materials |

| Cleaning | Easy, removable wire design | May require special care |

| Best Use | General broiling needs | Precise, fast broiling for meats and vegetables |

Introduction to Broiling Techniques

Broiling uses intense, direct heat to cook food quickly, emphasizing the Maillard reaction for rich flavor and texture. Wire racks allow air circulation and even heat distribution, promoting consistent browning.

Infrared racks emit radiant heat that penetrates food more deeply, reducing cooking time and enhancing caramelization. Choosing between wire and infrared racks depends on desired cooking speed and flavor intensity.

What is a Wire Rack?

| Wire Rack | A wire rack is a metal grid structure used in broiling to elevate food, allowing heat to circulate evenly for optimal cooking results. Typically made from stainless steel or chrome-plated steel, wire racks withstand high temperatures and promote better airflow compared to solid surfaces. Its design prevents food from sitting in rendered fats, enhancing crispness and reducing sogginess during the broiling process. |

What is an Infrared Rack?

An infrared rack is a specialized grilling accessory that emits intense infrared radiation, providing even and efficient heat distribution during broiling. This technology allows for faster cooking times and better browning compared to traditional wire racks.

- Infrared radiation - Produces high, direct heat ideal for searing and caramelizing food surfaces.

- Material composition - Typically made of ceramic or metal coated to withstand high temperatures and evenly distribute heat.

- Cooking efficiency - Reduces cooking time by concentrating heat closer to the food, ensuring thorough and consistent doneness.

Infrared racks enhance broiling performance by combining rapid heat transfer with precise temperature control.

Heat Distribution: Wire Rack vs Infrared Rack

Wire racks provide even heat distribution by allowing hot air to circulate around the food, which helps achieve uniform cooking. Infrared racks generate intense, focused heat that penetrates food quickly, offering faster browning but with less overall heat dispersion.

- Wire Rack promotes airflow - The open design of wire racks enables heat to flow evenly around the food, preventing hot spots.

- Infrared Rack delivers concentrated heat - Infrared technology emits radiant heat that targets food directly, enhancing searing and caramelization.

- Heat retention differences - Wire racks heat more gradually and maintain consistent temperatures, whereas infrared racks heat up rapidly but concentrate heat in smaller areas.

Cooking Speed Comparison

Which heats faster for broiling: a wire rack or an infrared rack? Infrared racks emit concentrated radiant heat, significantly reducing cooking time compared to traditional wire racks. Wire racks rely on ambient oven heat, resulting in slower, less intense heat transfer during broiling.

Food Texture and Browning Results

Wire racks promote even air circulation around the food, resulting in uniform browning and a crisp texture. The direct contact with the metal also helps achieve a well-defined sear on meats and vegetables during broiling.

Infrared racks use radiant heat that penetrates food more deeply, enhancing caramelization and producing a richer, more pronounced browning. This method often yields juicier interiors with a slightly softer crust compared to wire racks.

Ease of Cleaning and Maintenance

Wire racks are generally easier to clean as they can be removed and soaked or scrubbed without specialized tools. Infrared racks require careful maintenance to avoid damage to the heating elements and often need gentle cleaning methods to preserve their efficiency. Choosing wire racks simplifies upkeep, while infrared racks demand more precise attention to maintain optimal broiling performance.

Safety Considerations for Broiling

Wire racks provide stable support but may cause uneven heat distribution during broiling, requiring careful placement to avoid flare-ups and burns. Infrared racks offer more consistent heat, reducing the risk of undercooked spots, but must be used with caution to prevent overheating and potential fire hazards.

Choosing the right rack involves assessing heat tolerance and airflow, as wire racks allow better ventilation, minimizing smoke buildup, which enhances kitchen safety. Infrared racks, while efficient, can reach higher temperatures rapidly, so close monitoring is essential to avoid food charring or accidental contact burns. Proper maintenance and regular cleaning of both rack types are critical to prevent grease accumulation and reduce fire risks during broiling.

Best Foods for Each Rack Type

Wire racks excel at broiling thick cuts of meat like steaks and pork chops, allowing even heat circulation and fat drainage for a crispy exterior. Infrared racks are ideal for delicate foods such as fish and vegetables, providing intense radiant heat that sears quickly without drying. Choosing the right rack optimizes cooking results based on the food's texture and moisture content.

Related Important Terms

Infrared heat dispersion

Infrared racks provide superior heat dispersion by emitting consistent infrared radiation that evenly cooks food, reducing hotspots commonly found in wire racks. Wire racks rely on direct contact and convection, which can cause uneven broiling and less efficient heat transfer compared to infrared technology.

Wire rack searing

Wire racks excel in broiling by allowing direct air circulation around food, which enhances even heat distribution and achieves superior searing with crisp, caramelized surfaces. In contrast to infrared racks, wire racks provide better versatility for high-heat searing, making them ideal for browning steaks and vegetables quickly while retaining juiciness.

Radiant broiling surface

Wire racks provide even heat distribution through direct exposure to radiant heat, ensuring consistent broiling results, while infrared racks utilize infrared radiation for faster surface searing and more intense radiant heat transfer, ideal for achieving a crisp exterior. Infrared racks excel in maintaining high radiant temperatures with minimal heat loss, enhancing the broiling surface efficiency compared to conventional wire racks.

Nonstick broiler rack

Nonstick broiler racks on wire racks offer even heat distribution and easy cleanup, making them ideal for traditional broiling tasks. Infrared racks provide faster searing and high heat intensity but may risk sticking unless coated with advanced nonstick materials designed to withstand extreme temperatures.

Dual-zone broil racks

Dual-zone broil racks combine the even heat distribution of wire racks with the intense, direct heat of infrared racks, optimizing searing and caramelization during broiling. This hybrid design enhances cooking precision by maintaining distinct temperature zones, allowing for versatile preparation of proteins and vegetables with improved texture and flavor.

Micro-perforated infrared tray

Micro-perforated infrared trays provide superior heat distribution and enhanced browning compared to traditional wire racks during broiling, thanks to their ability to emit consistent infrared radiation. This technology allows for faster cooking times and improved searing by minimizing flare-ups and evenly penetrating heat through the micro-perforations.

High-density grill mesh

High-density grill mesh on wire racks provides even heat distribution and superior airflow, enhancing the broiling process by reducing flare-ups and ensuring consistent cooking. Infrared racks, while efficient in targeting heat, often lack the fine mesh structure that promotes optimal ventilation and uniform searing during broiling.

Direct flame broiler grid

Direct flame broiler grids, such as wire racks, offer superior heat circulation and even cooking by allowing flames to directly contact the food, enhancing caramelization and searing. Infrared racks, while effective at providing consistent radiant heat, often lack the open structure of wire racks, reducing direct flame exposure and consequently the intensity of broiling.

Rapid caramelization rack

An infrared rack accelerates rapid caramelization during broiling by delivering intense, evenly distributed heat that quickly seals and browns the food's surface. Wire racks, while effective for air circulation, lack the high radiant heat necessary for the faster Maillard reaction that infrared technology provides.

Wire rack vs infrared rack for broiling. Infographic

cookingdiff.com

cookingdiff.com