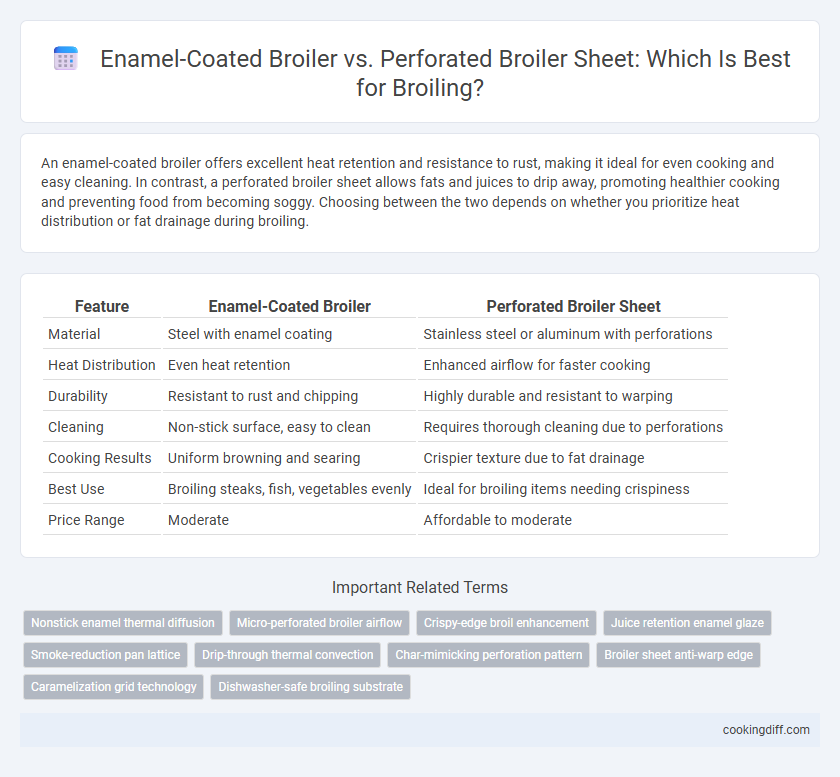

An enamel-coated broiler offers excellent heat retention and resistance to rust, making it ideal for even cooking and easy cleaning. In contrast, a perforated broiler sheet allows fats and juices to drip away, promoting healthier cooking and preventing food from becoming soggy. Choosing between the two depends on whether you prioritize heat distribution or fat drainage during broiling.

Table of Comparison

| Feature | Enamel-Coated Broiler | Perforated Broiler Sheet |

|---|---|---|

| Material | Steel with enamel coating | Stainless steel or aluminum with perforations |

| Heat Distribution | Even heat retention | Enhanced airflow for faster cooking |

| Durability | Resistant to rust and chipping | Highly durable and resistant to warping |

| Cleaning | Non-stick surface, easy to clean | Requires thorough cleaning due to perforations |

| Cooking Results | Uniform browning and searing | Crispier texture due to fat drainage |

| Best Use | Broiling steaks, fish, vegetables evenly | Ideal for broiling items needing crispiness |

| Price Range | Moderate | Affordable to moderate |

Introduction to Broiling: Tools Matter

Enamel-coated broilers provide a durable, non-stick surface ideal for even heat distribution during broiling, preventing food from sticking and making cleanup easier. Perforated broiler sheets allow fat and juices to drain away, promoting healthier cooking and enhanced browning by exposing food directly to the broiler's heat. Choosing the right tool can significantly impact cooking efficiency and final dish quality in broiling techniques.

What is an Enamel-Coated Broiler?

An enamel-coated broiler is a kitchen tool designed with a smooth, non-stick surface that resists high heat and prevents food from sticking during broiling. This coating ensures easy cleaning and durability under intense heat conditions compared to perforated broiler sheets.

- Heat Resistance - The enamel coating withstands high temperatures without cracking or peeling.

- Non-stick Surface - Facilitates even cooking and easy food release during the broiling process.

- Durability - More robust than perforated sheets, providing longevity and consistent performance.

Enamel-coated broilers offer enhanced cooking efficiency and effortless maintenance for broiling tasks.

Understanding Perforated Broiler Sheets

How does a perforated broiler sheet enhance the broiling process compared to an enamel-coated broiler? Perforated broiler sheets allow heat and air to circulate more evenly around food, promoting faster and more consistent cooking. These sheets also enable fat and juices to drip away, reducing smoke and improving the texture of broiled dishes for better flavor and health benefits.

Heat Distribution Comparison

Enamel-coated broilers provide even heat distribution due to their solid surface, which helps maintain consistent cooking temperatures. In contrast, perforated broiler sheets allow heat and air to circulate freely, promoting faster and more uniform browning of food.

- Enamel-coated broiler - The solid enamel surface retains and radiates heat evenly, reducing hot spots during broiling.

- Perforated broiler sheet - Holes in the sheet facilitate better airflow, enhancing the exposure of food to direct heat.

- Heat distribution impact - Enamel-coated broilers excel in steady heat retention, while perforated sheets optimize crisping through improved heat circulation.

Nonstick Properties: Enamel vs Perforated

Enamel-coated broilers offer superior nonstick properties due to their smooth, glass-like surface that prevents food from adhering and simplifies cleanup. This coating also resists staining and corrosion, enhancing durability during high-heat broiling.

Perforated broiler sheets, while allowing fat and juices to drain for healthier cooking, often lack nonstick features, causing food to stick and making cleaning more difficult. Some perforated sheets are coated with nonstick materials, but they generally wear out faster and require more maintenance than enamel surfaces.

Cleaning and Maintenance Differences

Enamel-coated broilers offer a non-porous surface that resists food sticking, making cleaning simpler with just warm soapy water and no abrasive scrubbers needed. The smooth finish prevents rust and staining, significantly reducing maintenance time compared to other materials.

Perforated broiler sheets with multiple holes allow drippings to fall through, but food particles can get trapped, requiring thorough scrubbing and occasional soaking for proper cleaning. These sheets often need more frequent maintenance to prevent buildup and corrosion due to their exposed metal and textured surface.

Durability and Lifespan

| Enamel-Coated Broiler | Offers excellent resistance to high heat and corrosion, providing a durable cooking surface that maintains its integrity over repeated use. The enamel coating prevents rust and enhances lifespan by protecting against chipping and wear during cleaning. With proper care, enamel-coated broilers can last several years without significant degradation. |

| Perforated Broiler Sheet | Constructed typically from stainless steel or aluminum, perforated broiler sheets offer good durability but are more prone to warping and surface corrosion over time, especially if not dried properly. While versatile and lightweight, their lifespan is generally shorter than enamel-coated options due to direct metal exposure and potential for chipping from contact with food or utensils. |

Performance with Various Foods

Enamel-coated broilers offer even heat distribution and are ideal for delicate foods like fish and vegetables, preventing sticking and ensuring consistent cooking. Perforated broiler sheets allow fat to drain away during cooking, enhancing browning and crisping for meats like chicken wings and burgers.

- Enamel-coated broiler - Provides non-stick surface suitable for fragile foods, reducing the risk of burning or tearing.

- Perforated broiler sheet - Promotes better airflow and fat drainage, resulting in crispier textures for fatty cuts of meat.

- Versatility - Enamel-coated broilers excel with moist, tender foods, while perforated sheets improve roasting and broiling of heavier, greasier items.

Health and Safety Considerations

Enamel-coated broilers provide a non-reactive, smooth surface that resists rust and bacterial buildup, promoting safer cooking environments. Their easy-to-clean nature minimizes contamination risks, making them a healthier choice for broiling.

Perforated broiler sheets allow fats and juices to drain away, reducing smoke and flare-ups that can produce harmful compounds. However, their porous surface may harbor bacteria if not cleaned thoroughly after use. Regular sterilization and inspection of both enamel-coated and perforated broilers are essential to maintain optimal health and safety standards during broiling.

Related Important Terms

Nonstick enamel thermal diffusion

Enamel-coated broilers provide superior nonstick properties and even thermal diffusion, preventing food from sticking while ensuring consistent heat distribution for optimal broiling results. In contrast, perforated broiler sheets allow fat and juices to drain but may compromise uniform heat transfer and risk food adhesion due to their open design.

Micro-perforated broiler airflow

Micro-perforated broiler sheets enhance airflow distribution during broiling, promoting even heat circulation and preventing food from steaming by allowing excess moisture to escape. Enamel-coated broilers provide a smooth, durable surface but typically lack the breathable design of micro-perforated sheets, making the latter superior for achieving crispy, evenly browned results.

Crispy-edge broil enhancement

Enamel-coated broilers provide even heat distribution and prevent food from sticking, enhancing crispy-edge broil results by maintaining consistent surface contact. Perforated broiler sheets improve air circulation and fat drainage, resulting in crispier edges and less sogginess for broiled foods.

Juice retention enamel glaze

Enamel-coated broilers offer superior juice retention due to their non-porous, smooth glaze that prevents moisture loss during broiling, enhancing flavor and tenderness. Perforated broiler sheets allow better heat circulation but often cause juices to drip away, resulting in drier food compared to the enamel-coated option.

Smoke-reduction pan lattice

An enamel-coated broiler with a smoke-reduction pan lattice traps drippings effectively, minimizing flare-ups and reducing smoke during broiling. In contrast, a perforated broiler sheet allows more direct heat exposure and drippings to fall through, increasing smoke but enhancing browning and crispiness.

Drip-through thermal convection

Enamel-coated broilers provide an even, radiant heat surface ideal for consistent cooking, while perforated broiler sheets enhance drip-through thermal convection by allowing fats and juices to escape, reducing smoke and promoting crispness. Perforated sheets improve airflow and heat circulation beneath the food, resulting in faster cooking times and a healthier, less greasy outcome.

Char-mimicking perforation pattern

Enamel-coated broilers offer a smooth, non-stick surface ideal for even heat distribution but may lack the authentic charred texture during broiling. Perforated broiler sheets with a char-mimicking perforation pattern enhance airflow and promote realistic searing marks, replicating traditional open-flame grilling results more effectively.

Broiler sheet anti-warp edge

Enamel-coated broiler sheets feature an anti-warp edge that maintains structural integrity under high heat, preventing warping and ensuring even cooking performance. Perforated broiler sheets with anti-warp edges enhance airflow while resisting deformation, promoting consistent broiling and durability.

Caramelization grid technology

Enamel-coated broilers feature a smooth surface that promotes even heat distribution but may limit airflow, whereas perforated broiler sheets with Caramelization grid technology enhance airflow and direct heat to food for superior caramelization and crisping. The perforated design allows fats to drain away while maximizing contact with hot air, resulting in faster Maillard reactions and richer flavor development during broiling.

Enamel-coated broiler vs Perforated broiler sheet for broiling. Infographic

cookingdiff.com

cookingdiff.com