Candying involves soaking fruit in sugar syrup, creating a thick, sweet coating that enhances flavor and extends shelf life by reducing moisture content. Edible film coatings form a thin, transparent layer made from natural polymers, which acts as a barrier to oxygen and moisture, preserving freshness without altering taste. While candying adds sweetness and texture, edible films maintain the fruit's original flavor and provide a more subtle preservation method.

Table of Comparison

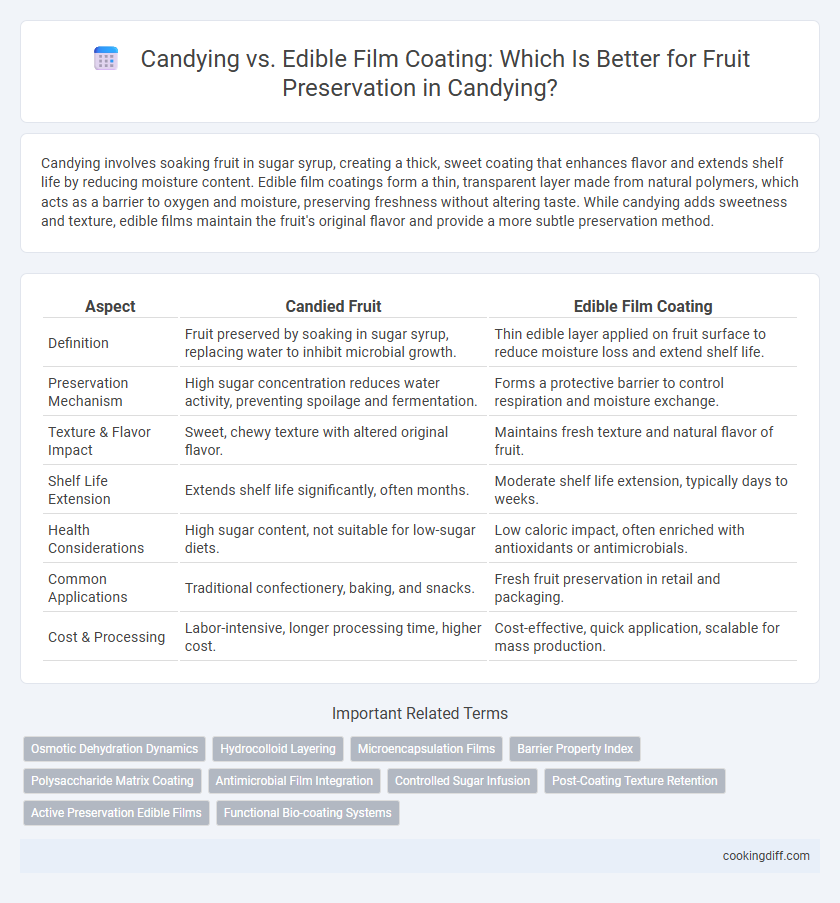

| Aspect | Candied Fruit | Edible Film Coating |

|---|---|---|

| Definition | Fruit preserved by soaking in sugar syrup, replacing water to inhibit microbial growth. | Thin edible layer applied on fruit surface to reduce moisture loss and extend shelf life. |

| Preservation Mechanism | High sugar concentration reduces water activity, preventing spoilage and fermentation. | Forms a protective barrier to control respiration and moisture exchange. |

| Texture & Flavor Impact | Sweet, chewy texture with altered original flavor. | Maintains fresh texture and natural flavor of fruit. |

| Shelf Life Extension | Extends shelf life significantly, often months. | Moderate shelf life extension, typically days to weeks. |

| Health Considerations | High sugar content, not suitable for low-sugar diets. | Low caloric impact, often enriched with antioxidants or antimicrobials. |

| Common Applications | Traditional confectionery, baking, and snacks. | Fresh fruit preservation in retail and packaging. |

| Cost & Processing | Labor-intensive, longer processing time, higher cost. | Cost-effective, quick application, scalable for mass production. |

Introduction to Fruit Preservation Techniques

Candying involves infusing fruit with sugar syrup to extend shelf life by reducing water activity and inhibiting microbial growth. This method enhances texture and flavor while preserving natural fruit colors.

Edible film coating creates a thin, protective layer over fruit surfaces using materials like polysaccharides or proteins, minimizing moisture loss and oxygen exposure. Both techniques aim to maintain freshness but employ different preservation mechanisms for improved fruit longevity.

What is Candying?

Candying is a preservation method that involves soaking fruit in sugar syrup to replace its water content, thereby inhibiting microbial growth and enzymatic activity. This process enhances the fruit's shelf life while imparting a sweet flavor and chewy texture.

Candying differs significantly from edible film coating, which creates a protective barrier to reduce moisture loss and oxidation without altering the fruit's texture or taste. The sugar infusion in candying provides both preservation and flavor enhancement, whereas edible films primarily aim to maintain freshness and appearance. Candying is especially effective for fruits like citrus peels and cherries, preserving them for extended periods in confectionery applications.

What is Edible Film Coating?

Edible film coating is a thin layer of edible material applied to the surface of fruit to extend shelf life and maintain freshness by acting as a barrier to moisture, oxygen, and microbial contamination. This technology uses natural substances like polysaccharides, proteins, or lipids, which are safe for consumption and environmentally friendly. Unlike candying, which involves sugar infusion to preserve fruit, edible film coating maintains the fruit's natural texture and flavor without altering its original taste profile.

Historical Context: Candying vs Edible Coatings

How have candying and edible film coatings evolved historically for fruit preservation? Candying dates back to ancient times, using sugar to preserve fruit by creating a protective, sweet barrier that inhibits microbial growth. Edible film coatings emerged more recently with advances in food science, employing biodegradable materials to extend shelf life while maintaining fruit quality and appearance.

Process Overview: How Candying Preserves Fruit

Candying preserves fruit by immersing it in a concentrated sugar solution that replaces the natural water content, effectively inhibiting microbial growth and enzymatic reactions. This process enhances shelf life while imparting a sweet flavor and firm texture to the fruit.

- Sugar Saturation - High sugar concentration creates osmotic pressure that draws out moisture from fruit cells, minimizing spoilage.

- Dehydration - Partial dehydration during candying reduces the water activity essential for microbial survival.

- Flavor and Texture Maintenance - Candying locks in natural fruit flavors and maintains firmness compared to edible film coatings.

Process Overview: How Edible Film Coatings Work

Edible film coatings preserve fruit by forming a thin, semi-permeable barrier that regulates gas exchange and moisture loss, extending shelf life and maintaining freshness. These coatings often consist of natural polymers like cellulose, chitosan, or alginate, which create a protective layer without altering the fruit's taste or texture. Unlike candying, which involves sugar infusion to enhance flavor and preservation, edible film coatings focus on maintaining the fruit's natural qualities while preventing microbial growth and oxidation.

Comparative Analysis: Taste and Texture

Candying fruit enhances its sweetness and imparts a chewy texture by saturating it with sugar, which also acts as a natural preservative. This method intensifies the fruit's flavor profile but often results in a denser, less juicy bite compared to fresh fruit.

Edible film coating preserves the fruit's natural taste and crispness by forming a thin, protective layer that reduces moisture loss and oxidation. Unlike candying, edible coatings maintain the original texture while providing a subtle barrier against spoilage, making them ideal for fresh fruit consumption.

Nutritional Impact of Each Method

| Preservation Method | Nutritional Impact |

|---|---|

| Candying | Increases sugar content significantly, which can lead to a reduction in vitamin C and antioxidant levels due to high-temperature processing and sugar infusion. |

| Edible Film Coating | Maintains most original nutrients by creating a protective barrier that reduces oxidation and moisture loss without altering the fruit's natural composition. |

Commercial and Home Applications

Candying involves preserving fruit by infusing it with sugar syrup, creating a sweet, long-lasting product primarily used in confectionery industries and gourmet home cooking. Edible film coatings, made from biopolymers, form a thin protective layer to extend shelf life and maintain freshness, widely adopted in commercial fruit packaging and home preservation techniques.

- Commercial Candying - Used to produce premium candied fruits for bakery and confectionery markets with enhanced flavor and texture.

- Home Candying - Enables DIY preservation of seasonal fruits without refrigeration, extending usability for months.

- Edible Film Coating - Offers a breathable, moisture-resistant barrier that minimizes spoilage and reduces the need for plastic packaging.

Both methods support fruit preservation but differ significantly in processing, application, and sensory outcomes.

Related Important Terms

Osmotic Dehydration Dynamics

Candying preserves fruit by osmotically dehydrating it with high-concentration sugar solutions, extracting moisture to inhibit microbial growth and enhance shelf life. In contrast, edible film coatings act as semi-permeable barriers to reduce moisture loss but do not induce the osmotic dehydration dynamics that significantly alter fruit texture and sugar content during preservation.

Hydrocolloid Layering

Hydrocolloid layering in candying forms a thick, sugar-rich barrier that enhances fruit preservation by reducing moisture loss and microbial growth, creating a long-lasting shelf life. Edible film coatings, while also employing hydrocolloids, generate a thinner, more flexible layer that controls gas exchange and maintains fruit texture without significantly altering flavor or appearance.

Microencapsulation Films

Candying preserves fruit through sugar infusion, creating a dehydrated, high-sugar barrier that inhibits microbial growth and extends shelf life; microencapsulation films, a type of edible film coating, encapsulate active compounds around the fruit surface, offering controlled release of preservatives and enhanced protection against oxidation and moisture loss. Compared to candying, microencapsulation films provide a more uniform, thinner, and customizable protective layer without significantly altering texture or flavor, making them ideal for maintaining fruit freshness and nutritional quality.

Barrier Property Index

Candying offers a high Barrier Property Index (BPI) by creating a dense sugar matrix that effectively reduces moisture loss and microbial growth in fruit preservation, outperforming traditional edible film coatings. While edible films provide a thin protective layer, their lower BPI often results in less efficient barrier performance against oxygen and water vapor, making candying a more robust method for extending fruit shelf life.

Polysaccharide Matrix Coating

Polysaccharide matrix coatings in candying create a thick, sugar-based layer that enhances fruit preservation by reducing moisture loss and microbial growth, offering extended shelf life with a sweet flavor profile. Edible film coatings, composed mainly of biopolymer polysaccharides, form a thin, breathable barrier that maintains fruit texture and freshness without altering taste, optimizing gas exchange and reducing oxidation.

Antimicrobial Film Integration

Candying preserves fruit by infusing sugar to inhibit microbial growth, while edible film coatings incorporate antimicrobial agents like chitosan or essential oils for enhanced protection. Integrating antimicrobial films offers controlled release of bioactive compounds, extending shelf life and maintaining fruit quality more effectively than traditional candying methods.

Controlled Sugar Infusion

Candying involves the controlled sugar infusion process that replaces fruit water content with concentrated sugar syrup, effectively reducing microbial growth and extending shelf life. In contrast, edible film coating primarily creates a physical barrier to moisture and gas exchange without significantly altering the fruit's internal sugar levels.

Post-Coating Texture Retention

Candying enhances fruit preservation by infusing sugar that crystallizes on the surface, creating a firm texture that maintains fruit integrity post-coating. Edible film coatings form a thin, flexible barrier that retards moisture loss, but often result in softer textures that may compromise crispness after application.

Active Preservation Edible Films

Active preservation edible films enhance fruit shelf life by incorporating antimicrobial agents and antioxidants, providing a protective barrier that slows microbial growth and oxidative damage. Unlike traditional candying, which relies on sugar infiltration and dehydration to preserve fruit, these films offer a dynamic, controlled-release mechanism that maintains fruit quality without altering texture or flavor.

Candying vs Edible film coating for fruit preservation. Infographic

cookingdiff.com

cookingdiff.com